A high-efficiency cutting blade

A cutting insert and high-efficiency technology, used in milling cutters, metal processing equipment, milling machine equipment, etc., can solve the problems of rapid damage of the main cutting edge, large cutting allowance of the blade, abnormal wear of the blade edge, etc., to ensure the surface quality. , Improve the durability, protect the effect of the wiper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

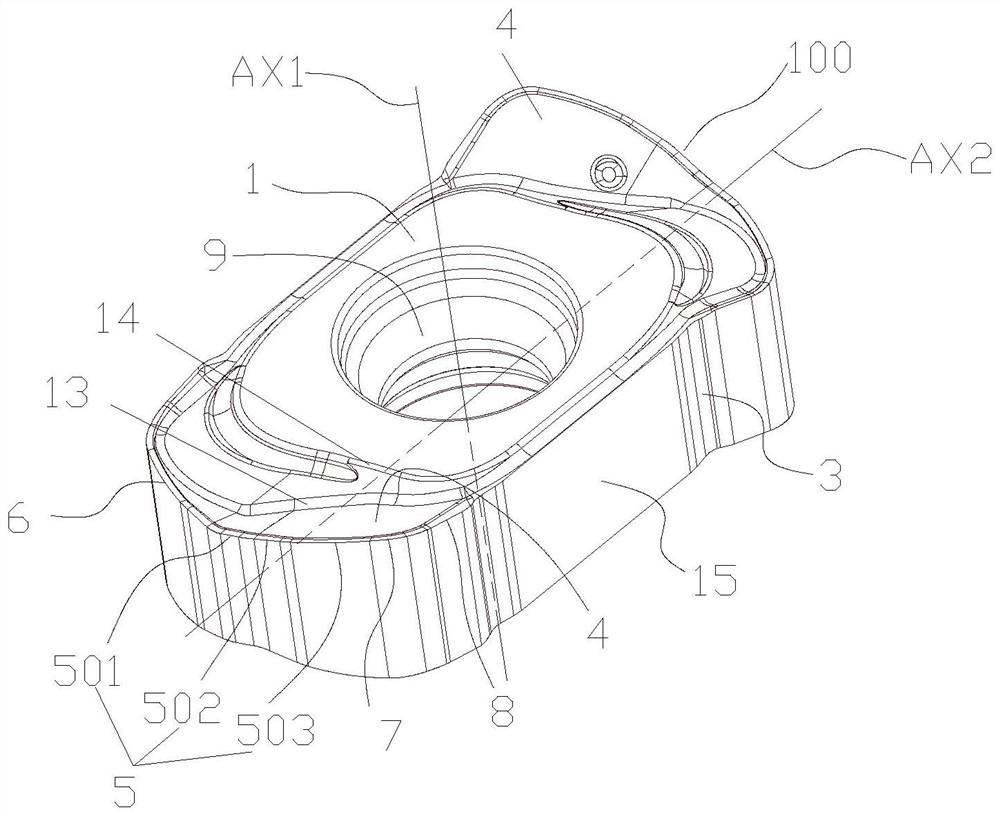

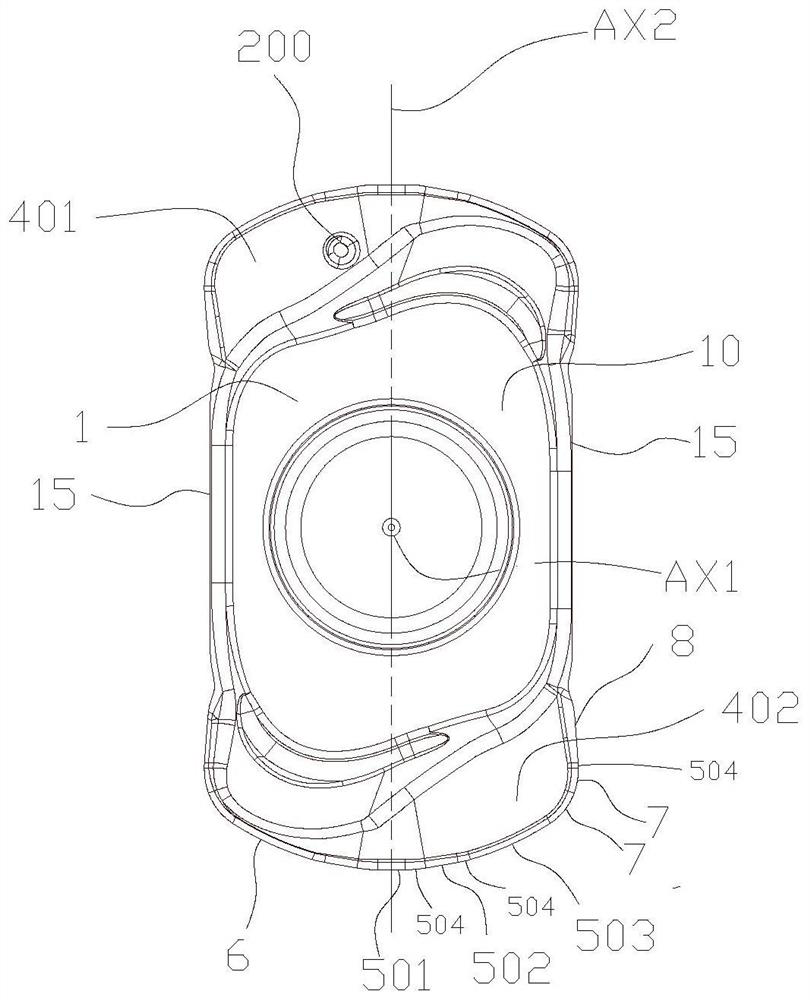

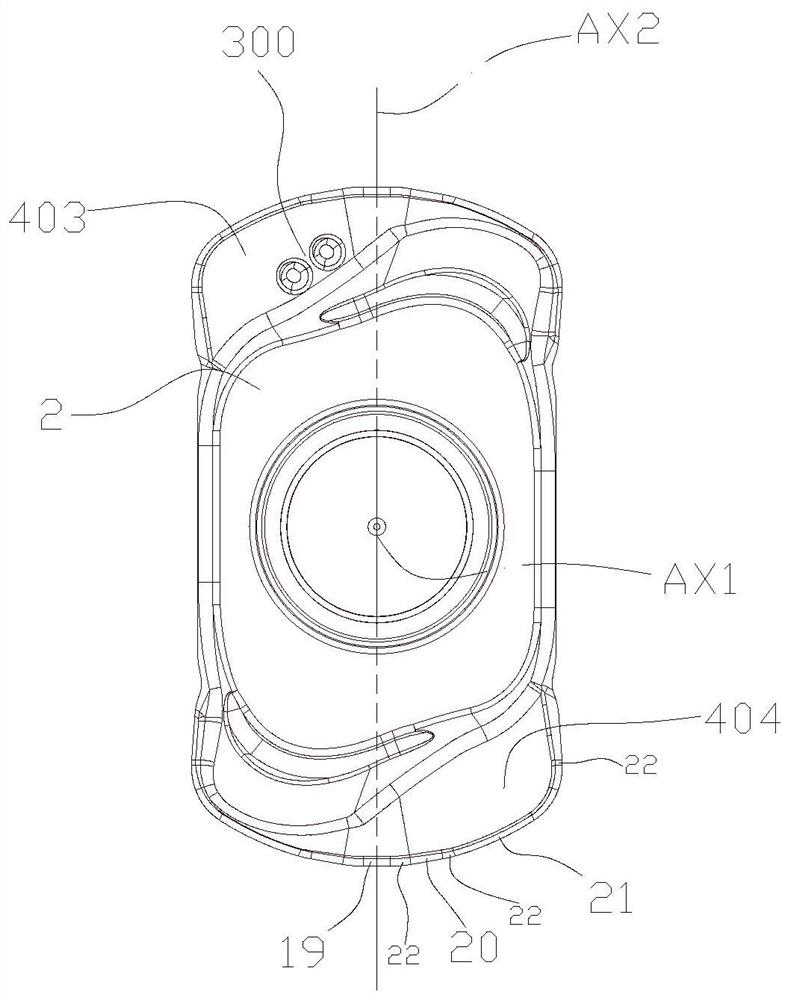

[0041] like figure 1 Shown is a high-efficiency cutting insert described in this embodiment, including an insert body 100 surrounded by an upper bottom surface 1, a lower bottom surface 2, and a side surface 3 connecting the upper bottom surface 1 and the lower bottom surface 2, the insert The cutting unit 4 is distributed on the main body 100, and the cutting unit 4 includes at least one main cutting edge 5. Under the cutting condition of a certain feed amount, the blade main body 100 and the part move relative to the main cutting edge 5 to promote the blade main body. 100 cuts into the interior of the part, forms curled chips on the rake face, and removes excess material; the main cutting edge 5 is composed of a wiper edge 501, a first cutting edge 502 and a second cutting edge 503. The wiper edge 501 is in a straight state, the wiper edge 501, the first cutting edge 502 and the second cutting edge 503 protrude toward the outer direction of the insert body 100 and form a spa...

Embodiment 2

[0061] like Figure 12 As shown, this embodiment differs from Embodiment 1 in the way of assembling the blade body 100 . Specifically, the blade body 100 can be rotated counterclockwise around the rotation center 28 for cutting processing, which widens the blade body 100 The use range of the blade body 100 enables all parts of the blade body 100 to function. The blade main body 100 is also installed on the blade body with a negative axial angle for cutting, and the cutting clearance angle is reserved. For the polishing effect of the surface of the part, the second secondary cutting edge undertakes the main work of removing the material of the part. At the same time, the secondary cutting edge and its secondary emptying edge will also participate in the actual cutting task in the case of a large depth of cut. At the same time, the secondary cutting edge 6 The first secondary cutting edge, the second secondary cutting edge and their bridging curves are all convex and curved tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com