Waste wood treatment equipment

A technology for processing equipment and wood, applied in the field of wood processing, can solve the problems of easily damaged pulverizing rollers and increase the use cost, and achieve the effect of improving the pulverization efficiency and reducing the use cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

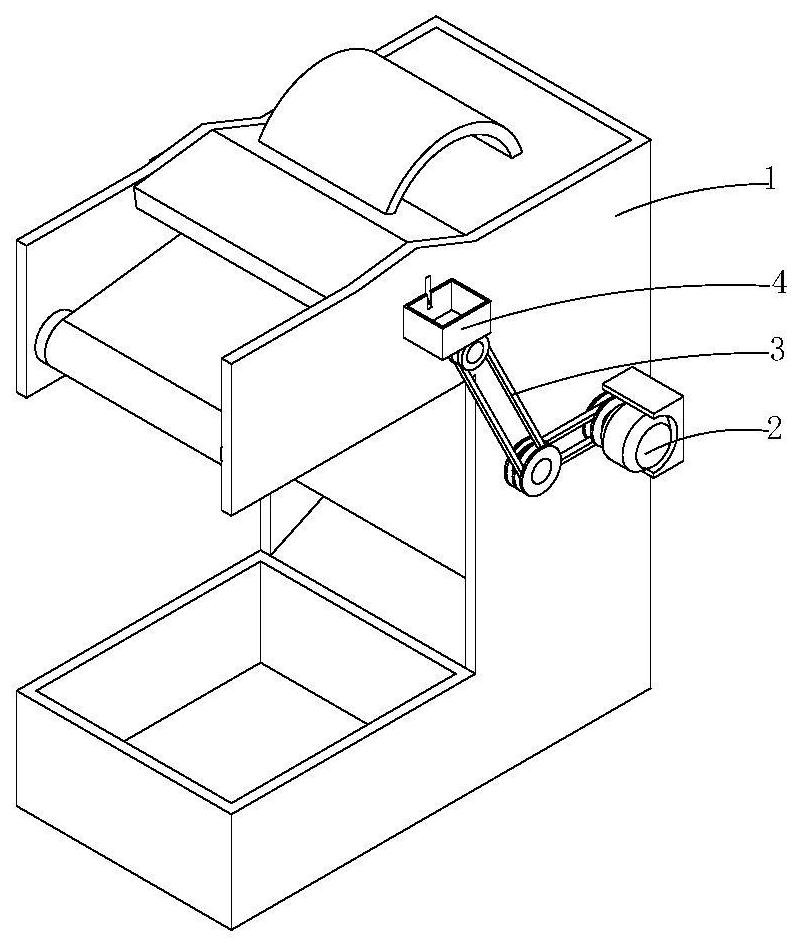

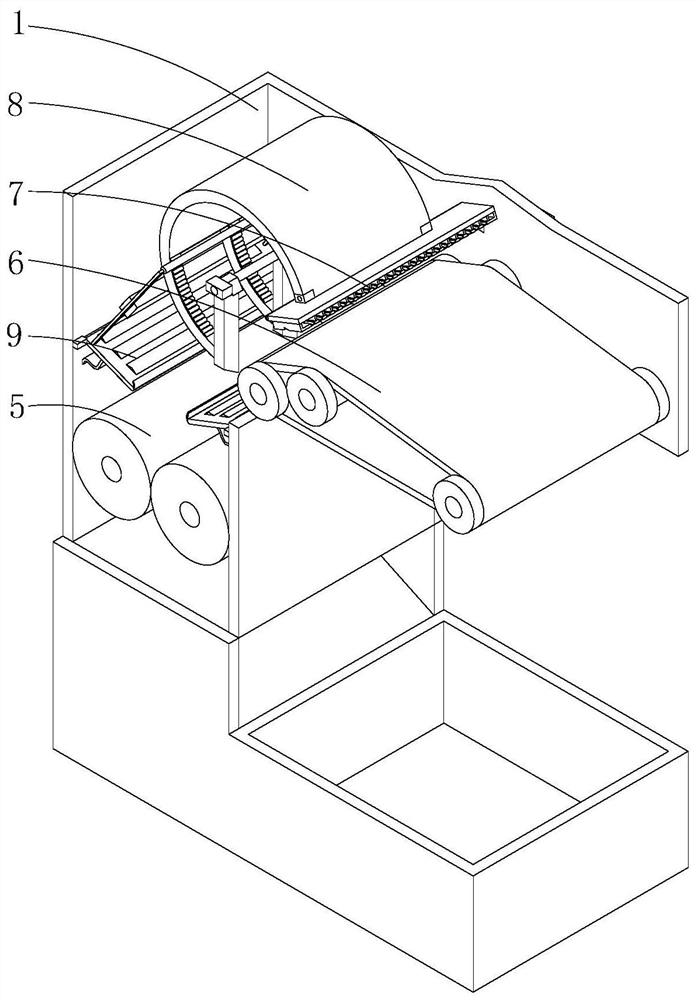

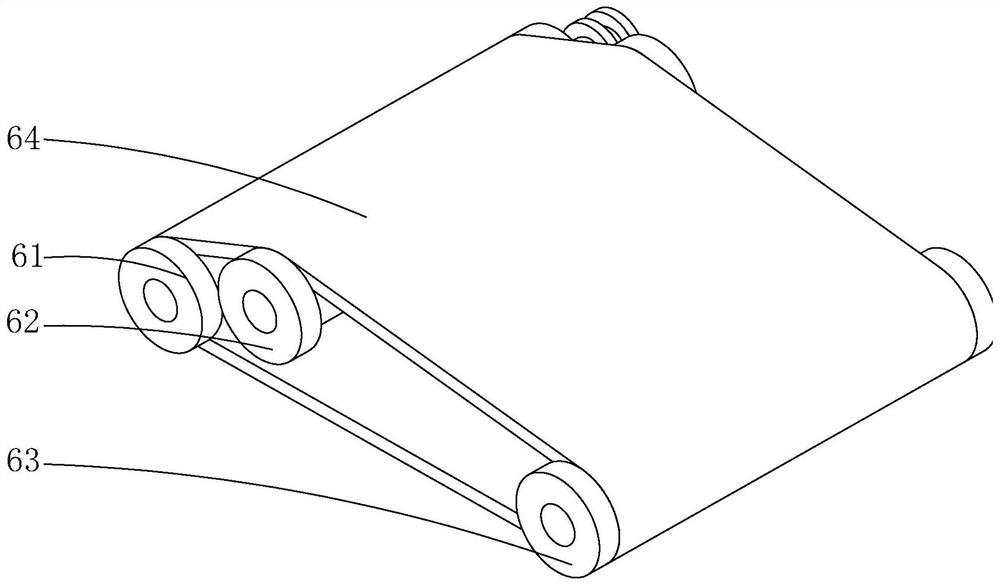

[0032] see Figure 1-11 , the present invention provides a technical solution: a kind of processing equipment for waste and old wood, including equipment casing 1, motor 2, pulley group 3, collection box 4 and crushing roller 5, the top of the inner wall of equipment casing 1 is bent, and through the equipment The top of the shell 1 is bent so that the equipment shell 1 cooperates with the second wheel 62 to bend and tear the waste wood. The top of the equipment shell 1 is provided with a chute that matches the arc-shaped plate 82. Through the equipment shell 1 The setting of the chute matching the arc plate 82 on the top enables the arc plate 82 to drive the nail re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com