Automatic continuous injection molding machine tool for silica gel products

An injection molding and product technology, applied in the field of silicone product processing, can solve the problems of taking up time, unable to operate continuously, uneven position, etc., to achieve the effect of improving the utilization rate and strengthening the applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

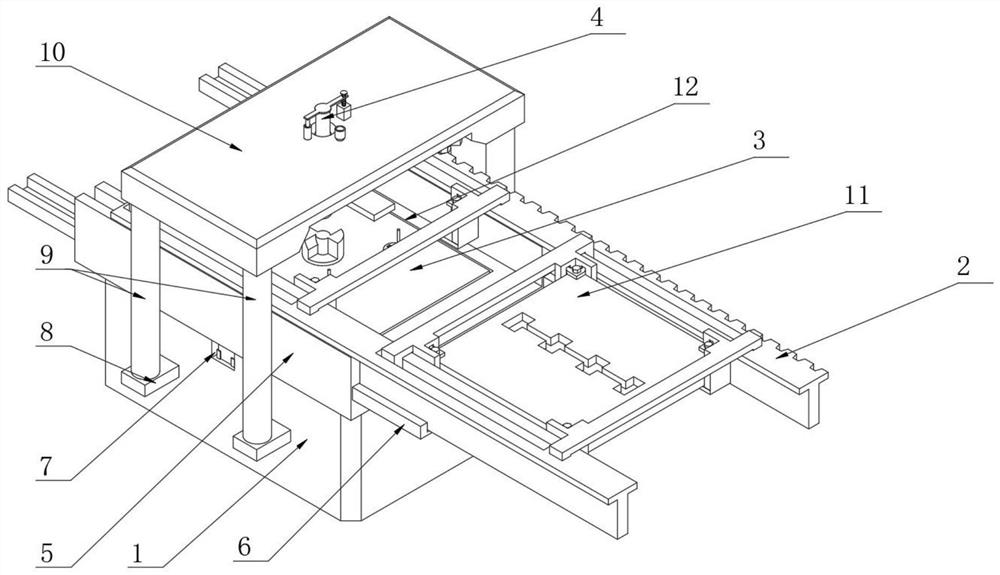

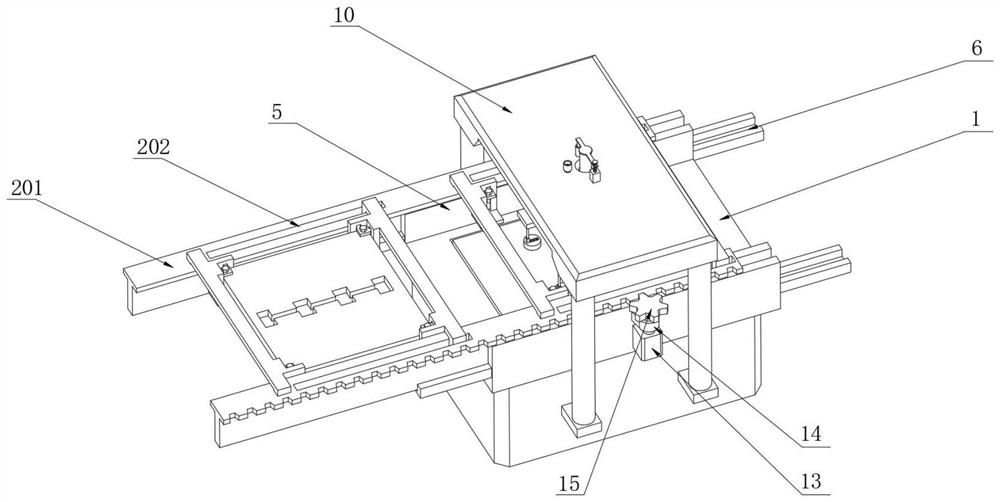

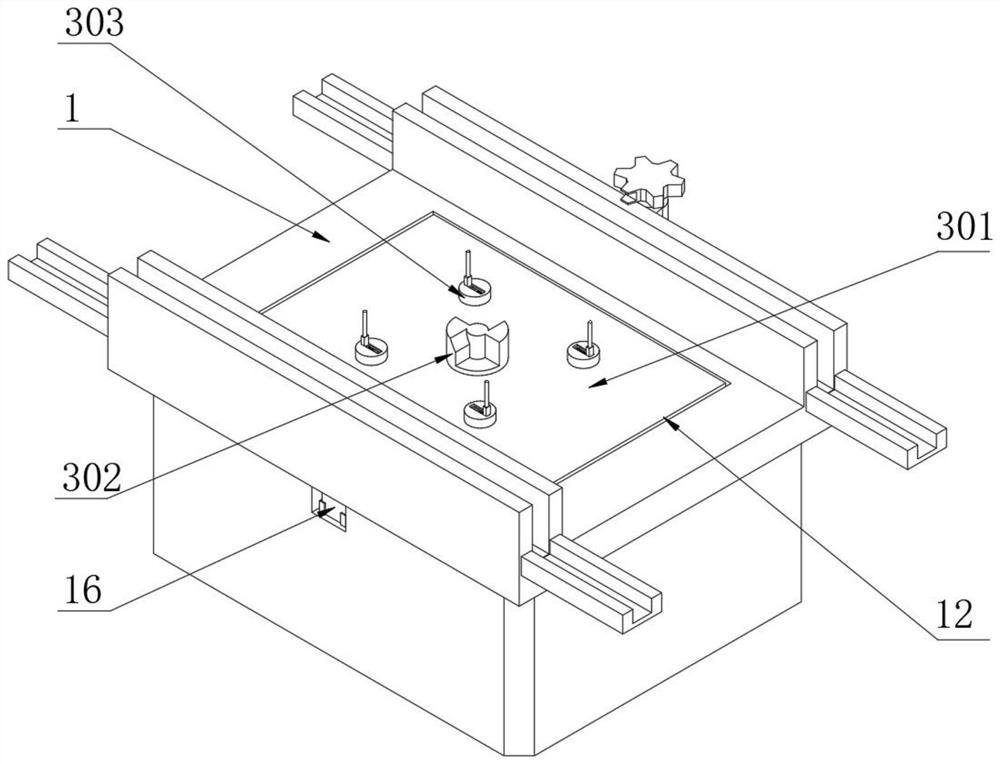

[0037] Such as Figure 1-13 As shown, an automatic continuous injection molding machine tool for silicone products, including a workbench 1, the two sides of the workbench 1 are respectively integrally provided with side extension plates 8, and the two sides of the upper surface of the workbench 1 are respectively integrally provided with The side slide frame 5, the center of the upper surface of the workbench 1 is provided with a reset card slot 12, the upper surface of each side extension plate 8 is fixedly installed with a support column 9, and the upper end of each support column 9 is fixedly installed with a mounting plate 10. An injection molding component 4 for silicone injection molding is installed at the center of the plate 10, and a matching component 3 is installed inside the worktable 1. The matching component 3 includes a transmission cavity 307, and the transmission cavity 307 is opened inside the workbench 1. Each side slide frame 5 Extended support frames 6 ar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap