Cloth setting machine

A sizing machine and cloth technology, applied in the processing of textile material drums, equipment configuration for processing textile materials, spraying/spraying of textile materials, etc., can solve problems such as adjusting the amount of water vapor ejected, reducing the effect of cloth setting, etc., to reduce slippage The probability of increasing the heat setting effect and the effect of increasing the contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following is attached Figure 1-2 The application is described in further detail.

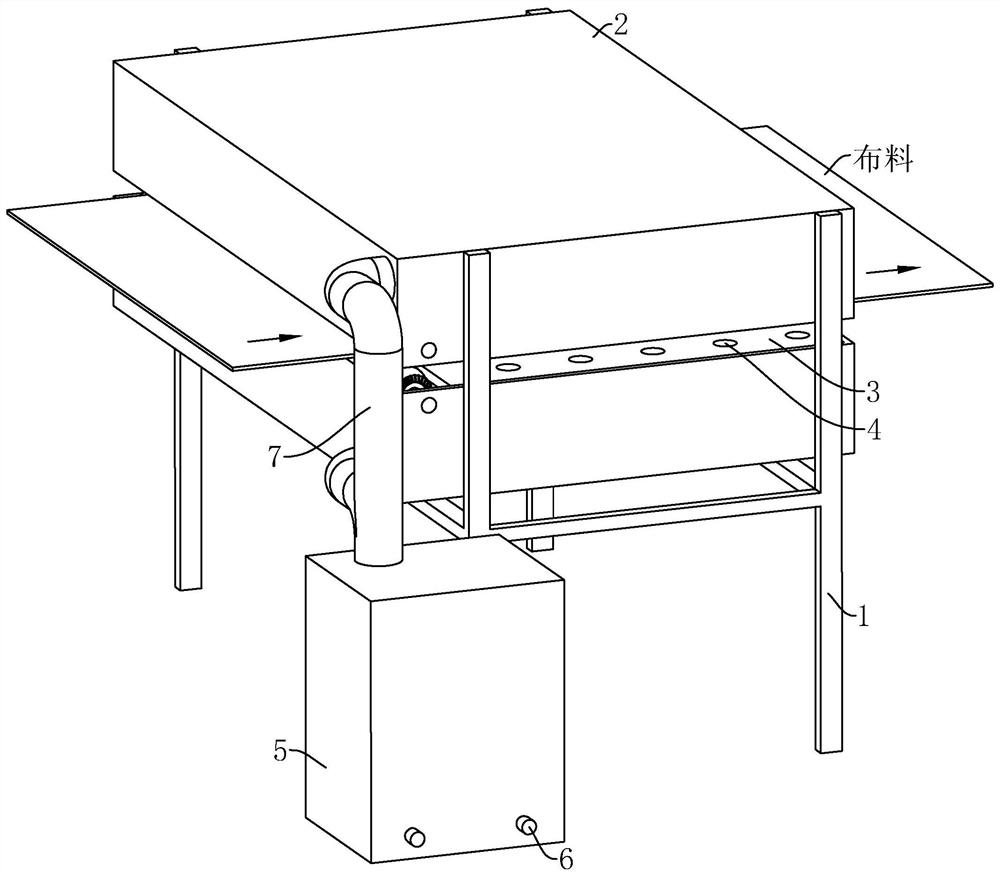

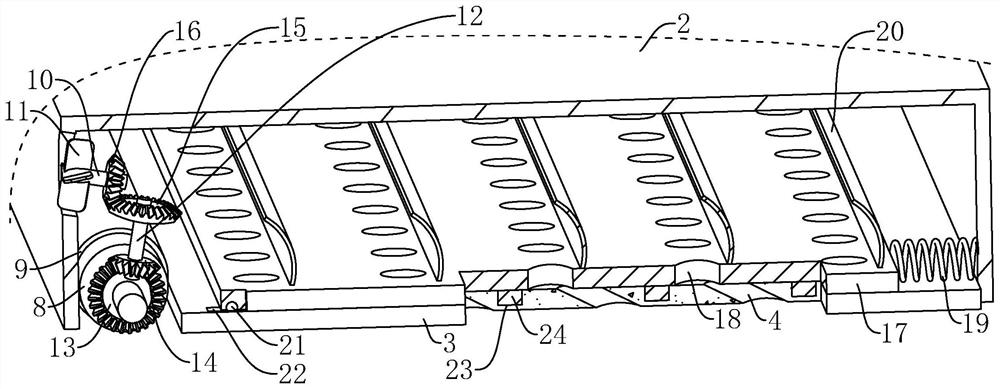

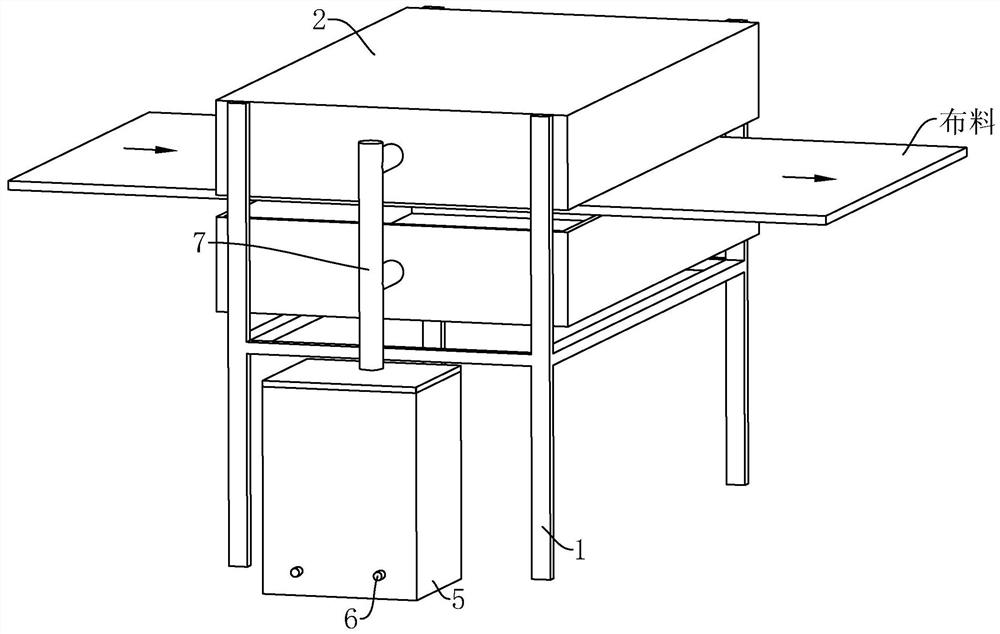

[0035] refer to figure 1 , a cloth setting machine, comprising a frame 1, two air outlet hoods 2 fixedly connected to the frame 1, the two air outlet hoods 2 are arranged symmetrically up and down, and there is a hole for the cloth to pass between the two air outlet hoods 2 gap, the opening of the air outlet cover 2 is equipped with a splitter plate 3, and the splitter plate 3 is evenly provided with multiple rows of first air outlet holes 4 for uniform spraying of water vapor; The water tank 5 containing clear water, the electric heating pipe 6 arranged inside the water tank 5, and the connecting pipe 7 communicating with the water tank 5 and the air outlet cover 2, the electric heating pipe 6 is connected with the power supply by electric wires. Workers start the electric heating tube 6 to heat the clean water. After the clean water is heated, water vapor will be formed. The wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com