Flexible and reliable pulse type self-propelled heating device

A heating device and reliable technology, applied in cooking utensils, household appliances, applications, etc., can solve problems affecting customer consumption experience, low efficiency, difficult cooking process continuity, streamlined operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

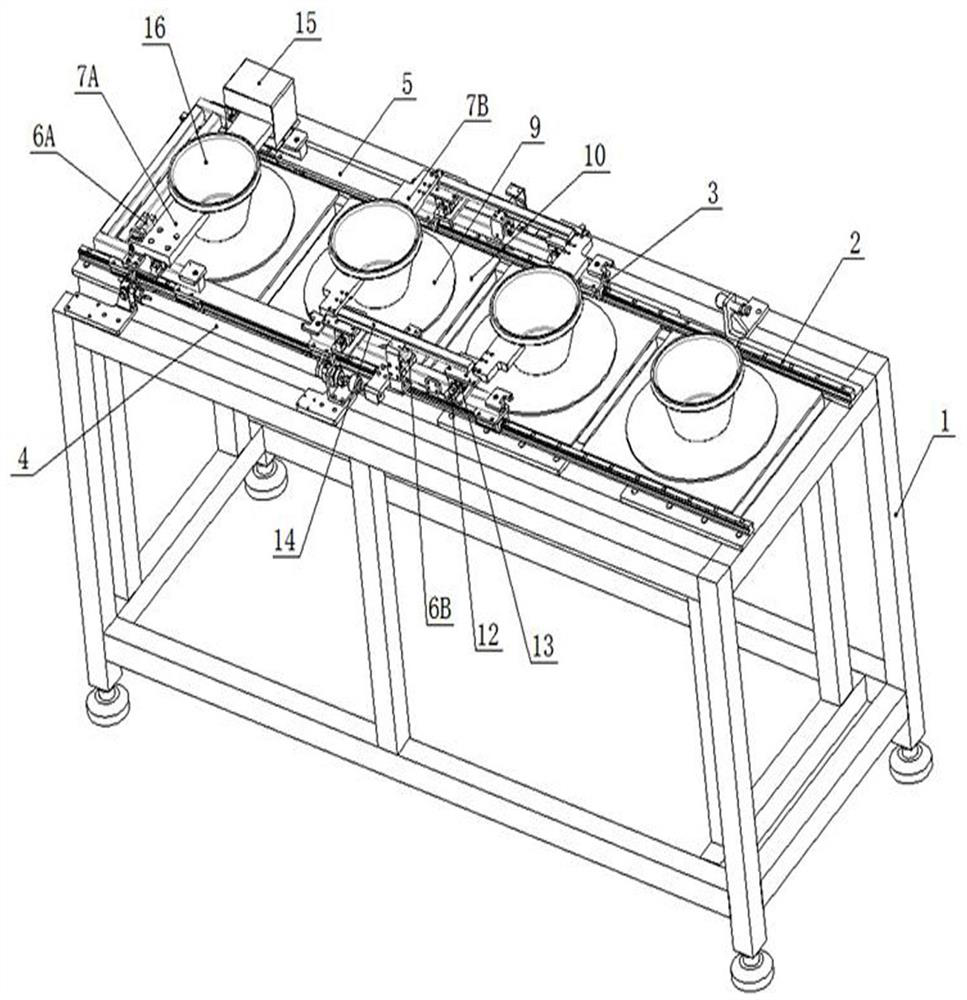

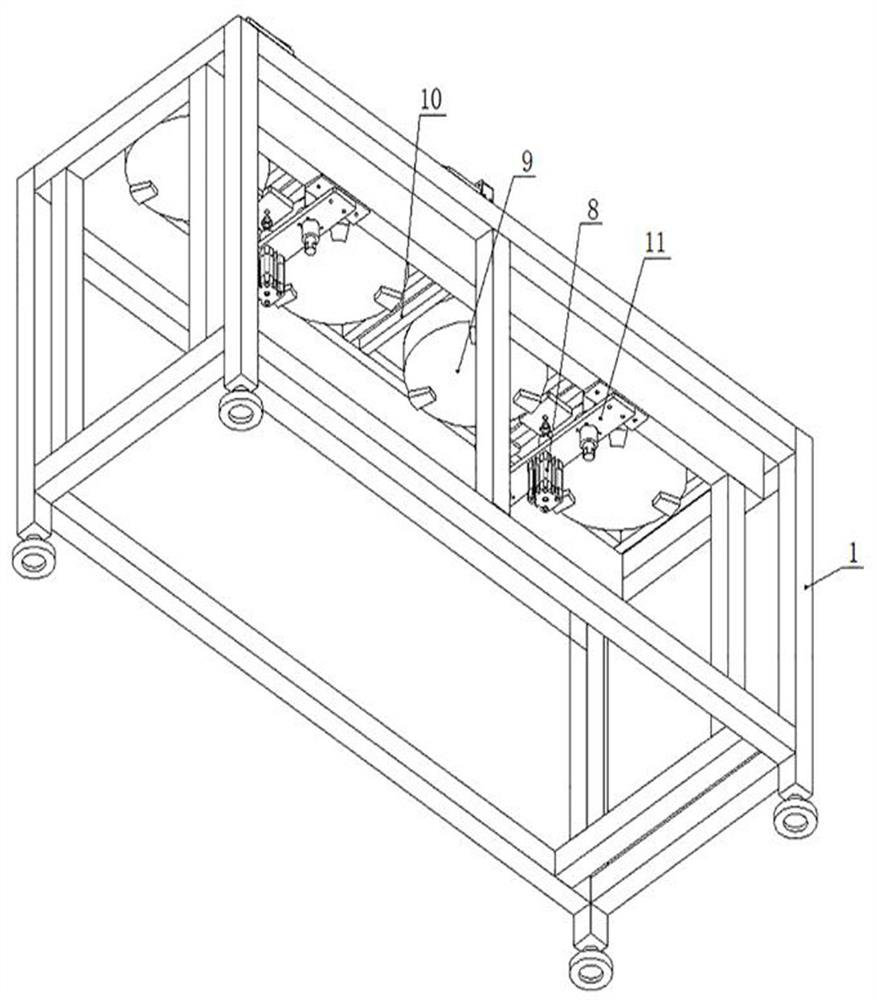

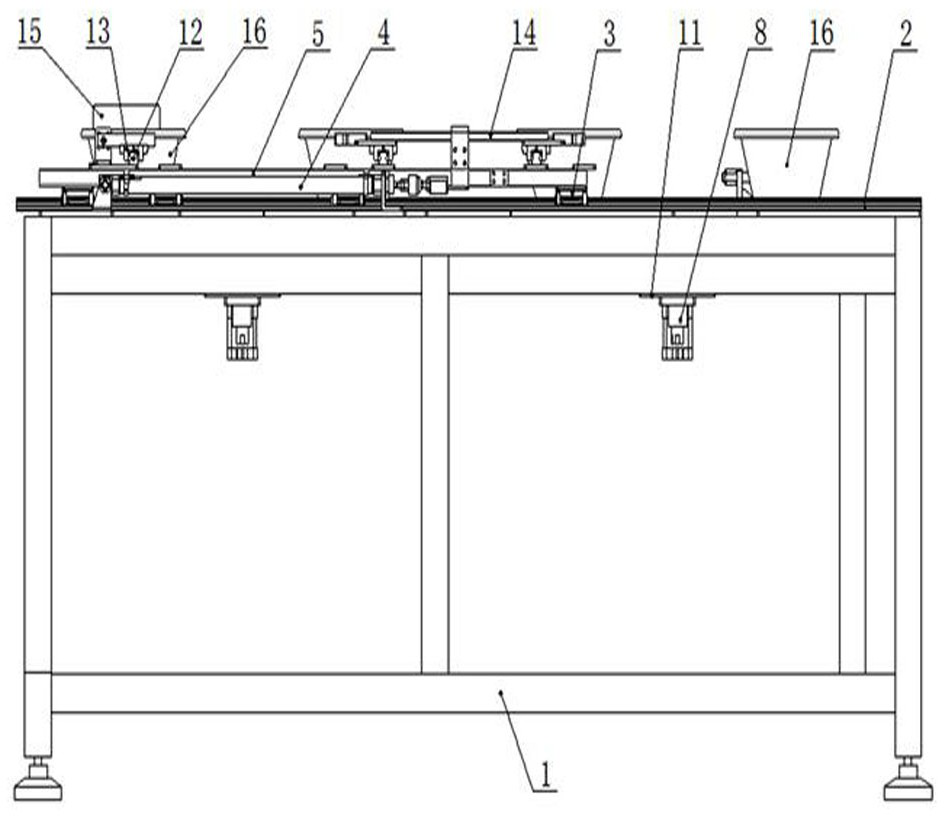

[0030] Such as Figures 1 to 3 Shown, with the present invention that has 4 electric furnaces 9 heating positions, cook small pot of rice noodles as an example, the working process is:

[0031] 1. Start the equipment, control system, supporting manipulator and each electric control part self-inspection, linear drive unit Ⅰ4, linear drive unit Ⅱ6 and linear drive unit Ⅲ8 return to the ready state according to the current state of each heating position, the manipulator returns to the origin, Complete equipment operation preparation.

[0032] 2. Judging the status of the heating position:

[0033]2.1 The first heating position reads the order information: the control system receives the pushed customer order information, and after receiving the new order, splits the order into preset single product information and puts it into the product queue, and obtains the product information from the product queue during operation ;

[0034] 2.2 The control system judges the processing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com