Production equipment for flat lifting belt

A technology for production equipment and hoisting belts, applied in the direction of measuring devices, textile material processing, textiles and papermaking, etc., can solve the problems of too many correction devices and the inability to monitor equipment in real time, so as to ensure position stability and level uniformity in real time The effect of monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

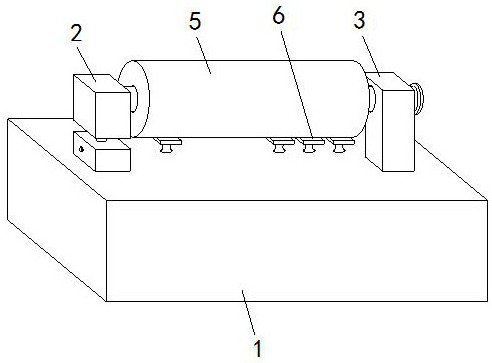

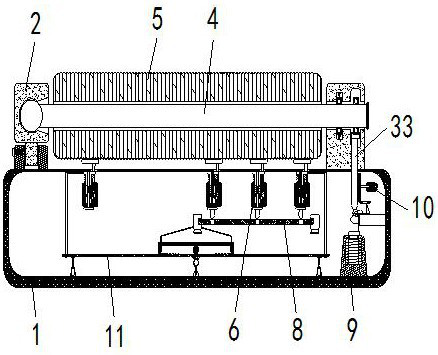

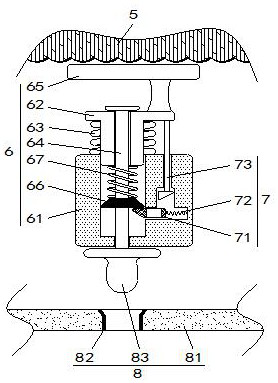

[0034] Such as Figure 1 to Figure 5 As shown, the production equipment of the flat lifting belt according to the present invention includes a workbench 1, on which a roll 5 is installed through a rotating shaft 4, and the inside of the workbench 1 and below the roll 5 are evenly distributed Driven assembly 6, the inside of workbench 1 and below driven assembly 6 are equipped with sensing assembly 8; during work, when roll 5 deflects, it will drive driven assembly 6 below it to move and communicate with sensing assembly 8 Contact, because the roll 5 is skewed, therefore, the amplitude of the driven assembly 6 at different positions being squeezed by the roll 5 is inconsistent, by counting the number of driven assemblies 6 that are in contact with the sensing assembly 8, you can The degree of deflection of the roll 5 is judged.

[0035] Two main mounts 2 are installed on the workbench 1, a rotating shaft 4 is installed between the two main mounts 2, and a roll 5 is installed o...

Embodiment 2

[0045] Such as Figure 6-7As shown in Comparative Example 1, another embodiment of the present invention is: the main mounting base 2 is provided with a positioning assembly 3, and the positioning assembly 3 includes a secondary bearing 31 and a main bearing 32 installed on the rotating shaft 4, A support spring set is installed on the secondary bearing 31, and a strut 33 is movably clamped under the main bearing 32, and the strut 33 is movably inserted into the inside of the workbench 1; when working, the right end of the rotating shaft 4 is installed on the main mounting seat through the bearing 2, as shown in Embodiment 1, the right end of the rotating shaft 4 is supported by the main bearing 32, the main bearing 32 is installed on the strut 33, and the strut 33 is fixed by the elastic rod 102 at the same time, therefore, the right end of the rotating shaft 4 is Installed on the support rod 33 with a fixed position, the two bearings play a double support role for the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com