A device and method for drilling sealed coring while drilling in coal seams and soft rock formations

A technology of airtight coring and rock strata, which is applied in the direction of extracting undisturbed core devices, earthwork drilling and mining, etc., can solve the problems of inaccurate acquisition of original gas information, inaccurate estimation of gas loss, and increased construction labor intensity, so as to shorten the exposure time Time, simple operation process, and the effect of reducing gas volume loss and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

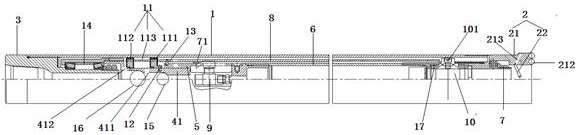

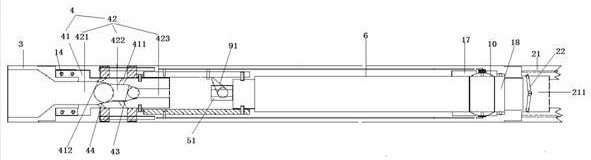

[0047] Comply with the above technical solutions, such as Figure 1 to Figure 4 As shown, this embodiment provides a kind of coal seam and soft rock layer drilling while drilling airtight coring device, including sampling outer cylinder 1, and the two ends of sampling outer cylinder 1 are respectively provided with sampling outer cylinder 1 coaxial and detachable fixed communication The sampling drill bit 2 and suspension joint 3;

[0048] The lower end of the suspension joint 3 extends into the sampling outer cylinder 1, the tail of the suspension joint 3 is provided with a bearing set 14, the bearing set is provided with a pressing ball seat 4, and the bottom of the pressing ball seat 4 is coaxially sleeved in turn to allow axial The moving connecting sleeve 5, the sampling inner cylinder 6 and the sampling inner cylinder connecting section 7;

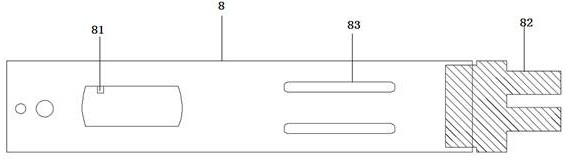

[0049] The connecting sleeve 5 and the sampling inner cylinder 6 are coaxially fitted with a push cylinder 8; the connecting sleev...

Embodiment 2

[0071] The target mine of this embodiment is a certain coal mine in Jincheng, and it is necessary to drill holes along the coal seam near the horizontal to carry out closed coring while drilling. The high-pressure fluid in this embodiment is high-pressure water.

[0072] Such as Figure 5 As shown, the present embodiment discloses a coal seam and soft rock layer drilling-while-drilling airtight coring method, which is realized by providing a coal seam and soft rock layer drilling-while-drilling airtight coring device in embodiment 1, including the following steps:

[0073] Step 1. Connect the suspension joint 3 with the drill pipe of the drilling rig, and drill the closed coring device while drilling from the hole to the preset coring point. During the drilling process, the inner hole cover plate 22 seals the inner hole channel 211 , the desorption valve 9 and the sealing ball valve 10 remain open;

[0074]Step 2. Put the first-stage plugging ball 15 into the drill pipe, inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com