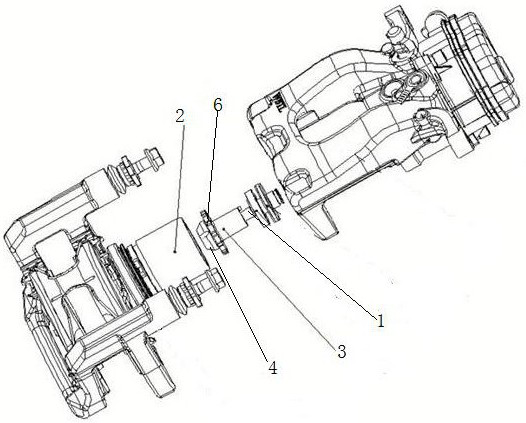

Internal limiting anti-rotation structure of driving brake caliper assembly

A technology of anti-rotation structure and limit structure, which is applied in the direction of brake actuators, brake parts, and axially joined brake parts, etc., which can solve problems such as prone to tilting, affecting stability, and poor assembly process. To achieve the effect of improving the relative axial tilt, improving the convenience of assembly, and ensuring the axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

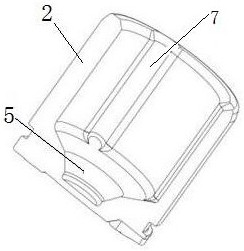

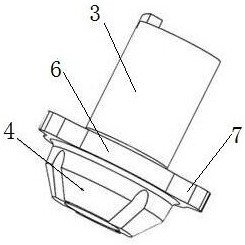

[0021] Such as Figure 4 As shown, the concave-convex limiting structure 7 adopts a groove and a boss structure, the groove is arranged on the inner side of the piston 2, the boss is arranged on the outer side of the limit block 6, the boss is snapped into the inner side of the groove, and is in contact with the surface of the groove Limiting and anti-rotation are performed, and the grooves and bosses are equidistantly distributed to ensure the supporting effect of the piston 2 on the brake screw sleeve 3, so that the brake screw sleeve 3 is kept axially placed.

Embodiment 2

[0023] Such as Figure 5 As shown, the concave-convex limiting structure 7 adopts a boss and a groove structure, the boss is arranged on the inner side of the piston 2, the groove is arranged on the outer side of the limit block 6, and the groove and the surface of the boss are in contact with each other to limit and prevent rotation. Both the bosses and the grooves are equidistantly arranged to ensure the supporting effect of the piston 2 on the brake screw sleeve 3 and keep the brake screw sleeve 3 placed axially.

Embodiment 3

[0025] Such as Figure 6 As shown, the concave-convex limiting structure 7 adopts a boss and a boss structure, and the bosses are respectively arranged on the inner side of the piston 2 and the outer side of the limiting block 6, and the boss in the piston 2 is in contact with the side of the boss on the outer side of the limiting block. Cooperate, the bosses are all non-equidistantly distributed, one or more bosses on the limit block 6 are located on the adjacent side of the inner boss of the piston, so that the bosses and bosses are in contact with each other to achieve forward and reverse directions of rotation. limit function.

[0026] The groove corresponding to the piston and the end area of the boss contain structural features such as chamfers or rounded corners to realize the guiding function of assembly.

[0027] The groove and the boss can choose circular arc structure and U-shaped groove structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com