A screw centering mechanism

A technology of centering mechanism and screw rod, which is applied in the direction of paper product packaging, packaging, packaging items, etc., can solve the problems of low production efficiency, high labor intensity, complex structure, etc., and achieve high production efficiency, stable and reliable work, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

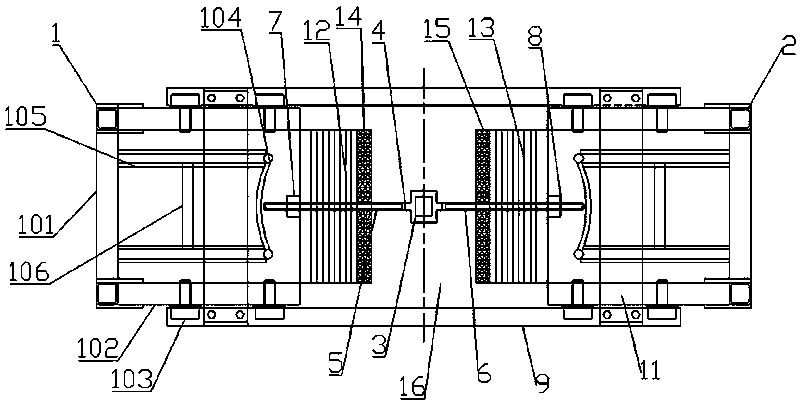

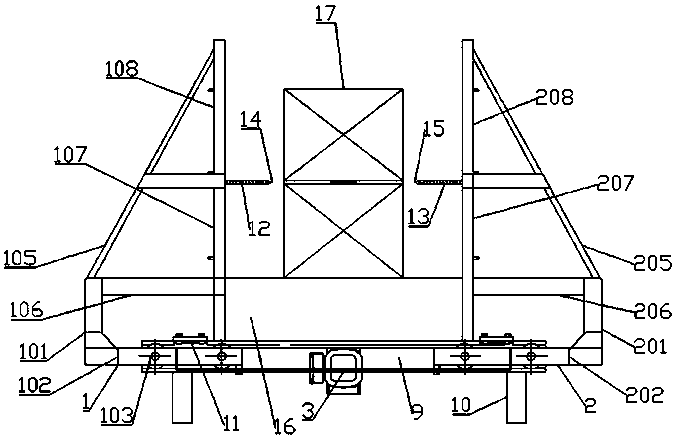

[0012] The specific implementation will be described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 , figure 2 As shown, a screw rod centering mechanism includes a left centering unit 1, a right centering unit 2, a centering motor 3, a screw rod 4, a left thread 5, a right thread 6, a left nut structure 7, and a right nut Structure 8, walking track 9, outrigger 10, connecting plate 11, left pulley rod 12, right pulley rod 13, left centering end 14, right centering end 15, centering bottom plate 16, cylindrical non-woven cloth roll 17 .

[0014] The left centering unit 1 and the right centering unit 2 are symmetrically arranged with respect to the whole mechanism, and the center point of symmetry is the center point of symmetry of the screw rod 4. The left centering unit includes a left support rod 101, a left cross bar 102, and a left traveling wheel 103 , the left straight bar 104, the left pull bar 105, the left transverse bar 106, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com