Cooling method and system for furnace gas cooler of waste sulfuric acid cracking furnace

A technology for coolers and cracking furnaces, applied in the direction of combustion methods, incinerators, combustion types, etc., can solve problems affecting production efficiency and long cooling time of cooling devices, so as to improve production efficiency, reduce maintenance time, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

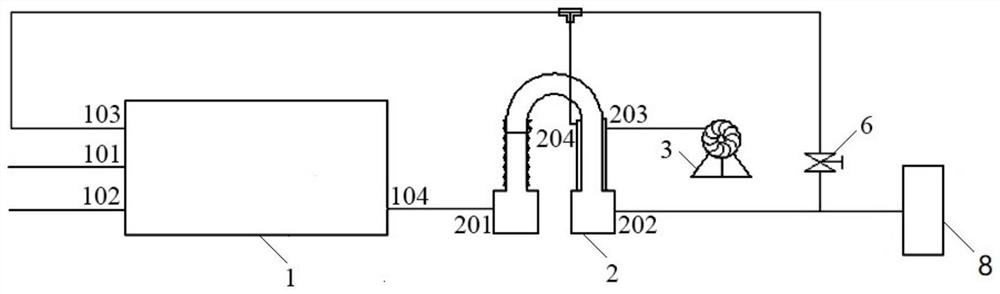

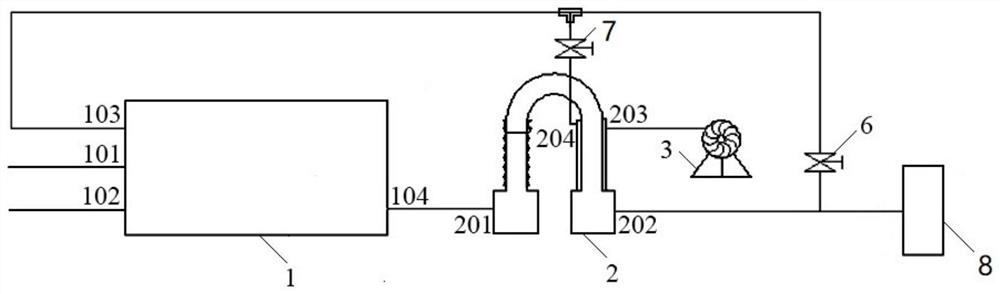

[0029] An implementation of this embodiment is as figure 1 shown.

[0030] A method for cooling the furnace gas cooler of a waste sulfuric acid cracking furnace, characterized in that it includes the operating state and the maintenance state,

[0031] Under the operation state, the furnace gas discharged from the cracking furnace 1 passes through the furnace gas cooler 2 into the furnace gas recovery module 8, and the air blower 3 sends air into the furnace gas cooler 2 and makes the air pass through the furnace gas cooler 2 Pass into cracking furnace 1, and described furnace gas cooler 2 heats air by furnace gas;

[0032] In the maintenance state, the air passes through the furnace gas cooler 2 into the furnace gas recovery module 8 , and the furnace gas from the cracking furnace 1 passes into the furnace gas recovery module 8 .

[0033] Principle description:

[0034] When in the running state, the cracking furnace 1 performs pyrolysis on the basis of the waste acid, fuel...

Embodiment 2

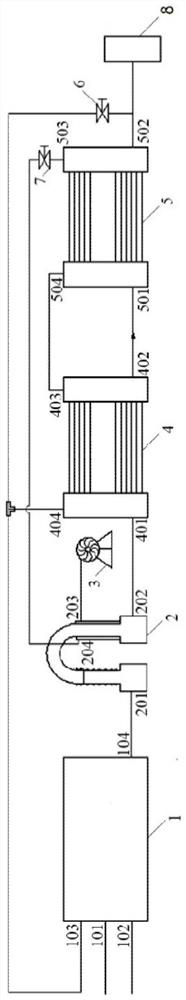

[0041] On the basis of Embodiment 1, in the operating state, the furnace gas discharged from the furnace gas cooler 2 passes through the air preheater and then passes into the furnace gas recovery module 8, and the gas discharged from the furnace gas cooler 2 Air passes through the cracking furnace 1 after passing through the air preheater;

[0042] In the maintenance state, the air discharged from the furnace gas cooler 2 passes through the air preheater and then passes into the furnace gas recovery module 8 .

[0043] The temperature of the furnace gas is further cooled by the air preheater, and the air is further heated, thereby improving the efficiency and effect of recovery and utilization of the waste heat of the furnace gas.

[0044] Preferably, the number of the air preheater is at least one, and in this embodiment, it is preferably two.

Embodiment 3

[0046] Such as figure 1 As shown, a waste sulfuric acid cracking furnace furnace gas cooler cooling system is characterized in that it includes a cracking furnace 1, a furnace gas cooler 2, an air blower 3, a first valve 6, and a furnace gas recovery module 8, and the cracking furnace 1 is provided with a natural gas inlet 101, a waste acid inlet 102, a furnace air inlet 103, and a furnace gas outlet 104, and the furnace gas cooler 2 is provided with a furnace gas cooler furnace gas inlet 201, a furnace gas cooler furnace gas outlet 202, Furnace gas cooler air inlet 203, furnace gas cooler air outlet 204,

[0047] The furnace inlet air inlet 103 and the furnace gas cooler air outlet 204 are connected, and the inlet of the furnace gas recovery module 8 is connected to the furnace inlet air inlet 103 and the furnace gas cooler air outlet 204 through the first valve 6 The pipelines between are communicated; the furnace gas outlet 104 is communicated with the furnace gas inlet 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com