High-voltage micro-current micro connector

A micro-connector and micro-current technology, which is applied in the direction of connection and connection device components, circuits, etc., can solve the problems of easy bending and deformation of the shrapnel, loose contact between the shrapnel and the terminal piece, and reduced elasticity, so as to achieve improved connection The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

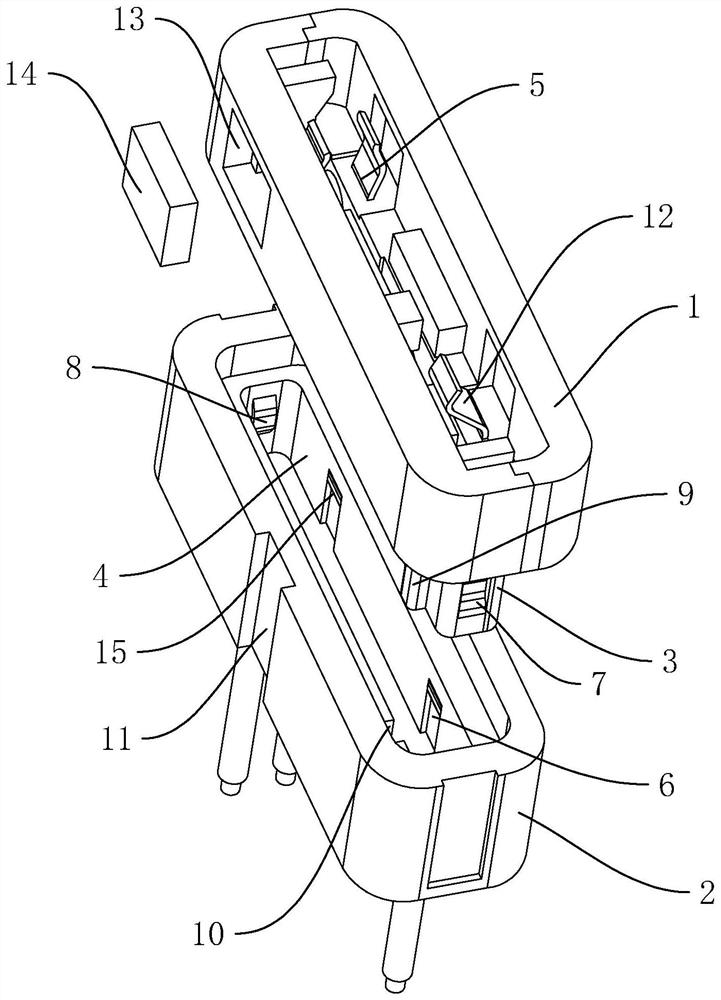

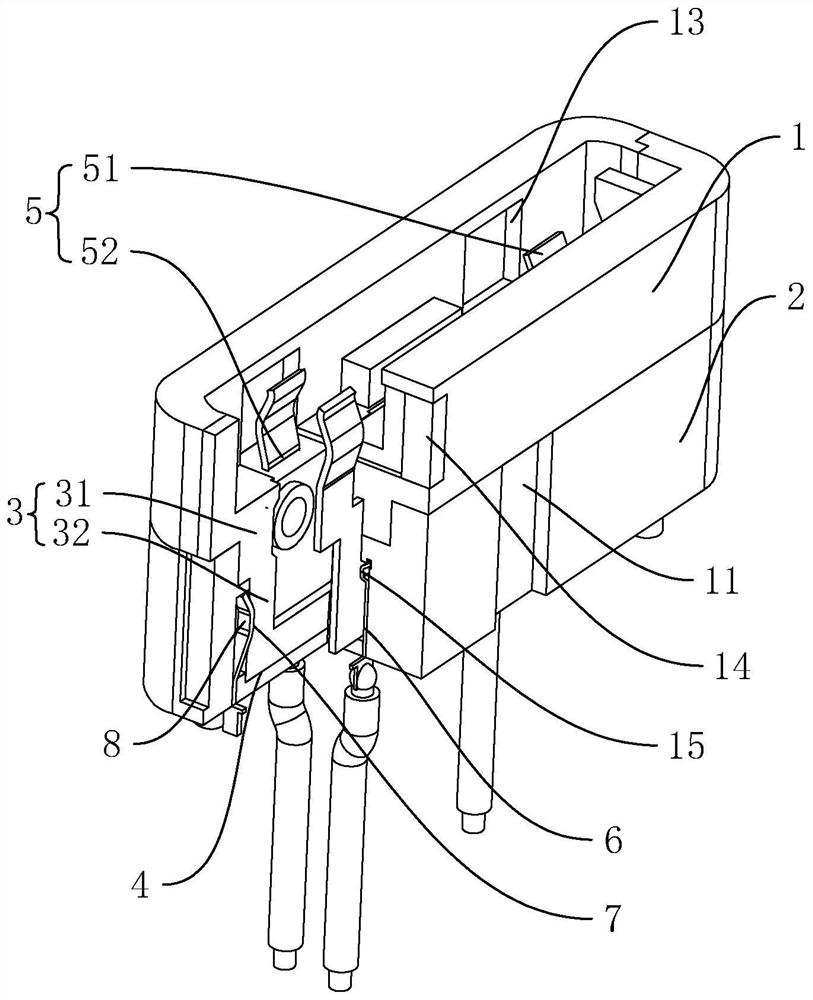

[0034] The following is attached Figure 1-2 The application is described in further detail.

[0035] The embodiment of the present application discloses a high-voltage micro-current micro-connector, refer to figure 1 , including a rectangular body 1 as a whole, a socket 2 connected to the body 1 and an insert block 3 integrally arranged on the body 1, a slot 4 is provided at one end of the width direction of the socket 2, and the insert block 3 is inserted into the slot 4, Electrode sheets 5 are embedded on both sides of the plug block 3 in the thickness direction. One end goes through the socket 2 and extends into the body 1, and the electrode piece 5 extends into the body 1 to connect the line of the fresh air device. The body 1 is spliced by two half-blocks. Block 3, the electrode sheet 5 on the half block is placed in the mold when the half block is poured, and is synchronously fixed on the half block when the half block is poured, and the corresponding electrode shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com