Pressing device for workpiece with notch and pin pressing device

A technology for pressing devices and workpieces, applied in workpiece clamping devices, manufacturing tools, metal processing, etc., can solve problems such as easy deformation, achieve the effects of ensuring stable processing, increasing swing stroke, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

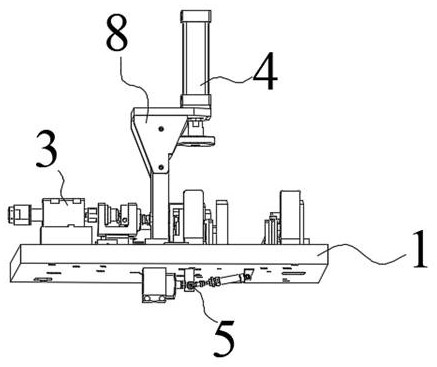

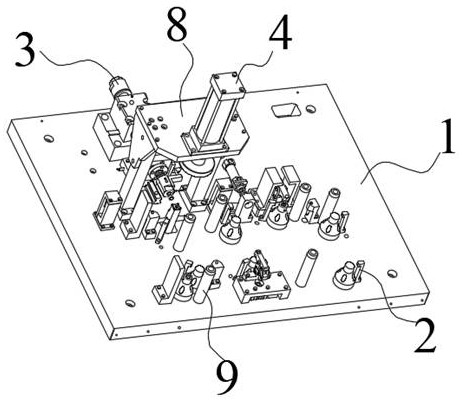

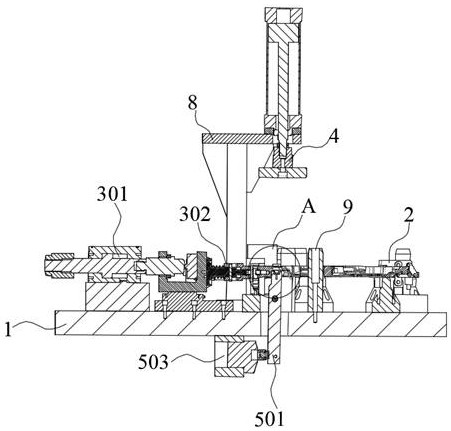

[0039] see Figure 1-6 , the compression device for workpieces containing notches in the preferred embodiment of the present invention is used to fix workpieces containing notches, and it includes a mounting seat 1, which is provided with a compression device for compressing and fixing the end surface of the workpiece. mechanism, on the mounting base 1 is also provided with an abutment mechanism 5, the abutment mechanism 5 is located on the side of the workpiece away from the pressing mechanism, and the end of the abutment mechanism 5 extends into the notch of the workpiece, and when the workpiece is processed At this time, the abutting mechanism 5 rotates and abuts against the side wall of the workpiece notch and applies an abutting force toward the side wall of the workpiece to be processed, such as figure 1 , 2 shown.

[0040]In the present invention, an abutment mechanism 5 is provided at the notch of the workpiece, and the inner wall of the notch is abutted by the abutm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com