Steel ingot mold

A technology of ingot mold and mold body, which is applied in manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc. The effect of energy consumption, reducing forging cycle and saving fire time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make those skilled in the art better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them. In the case of no conflict, the embodiments and the features in the embodiments of the present invention can be combined with each other.

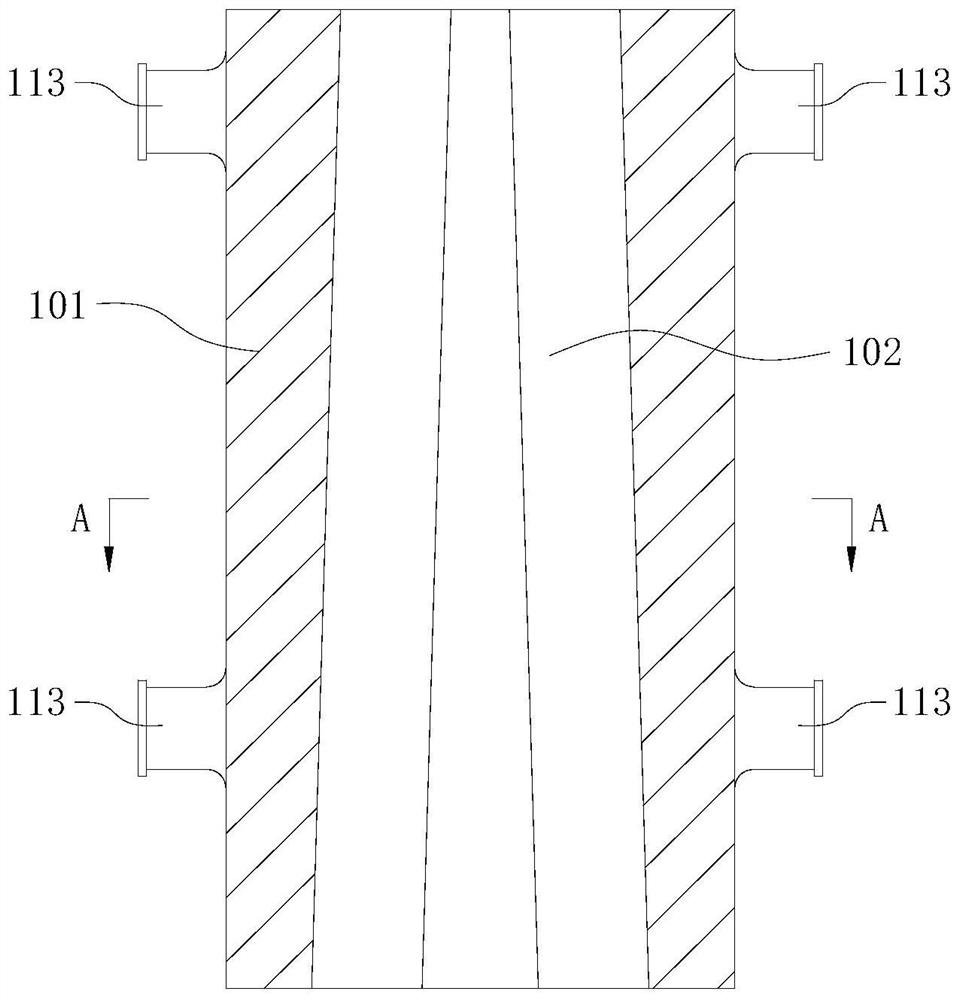

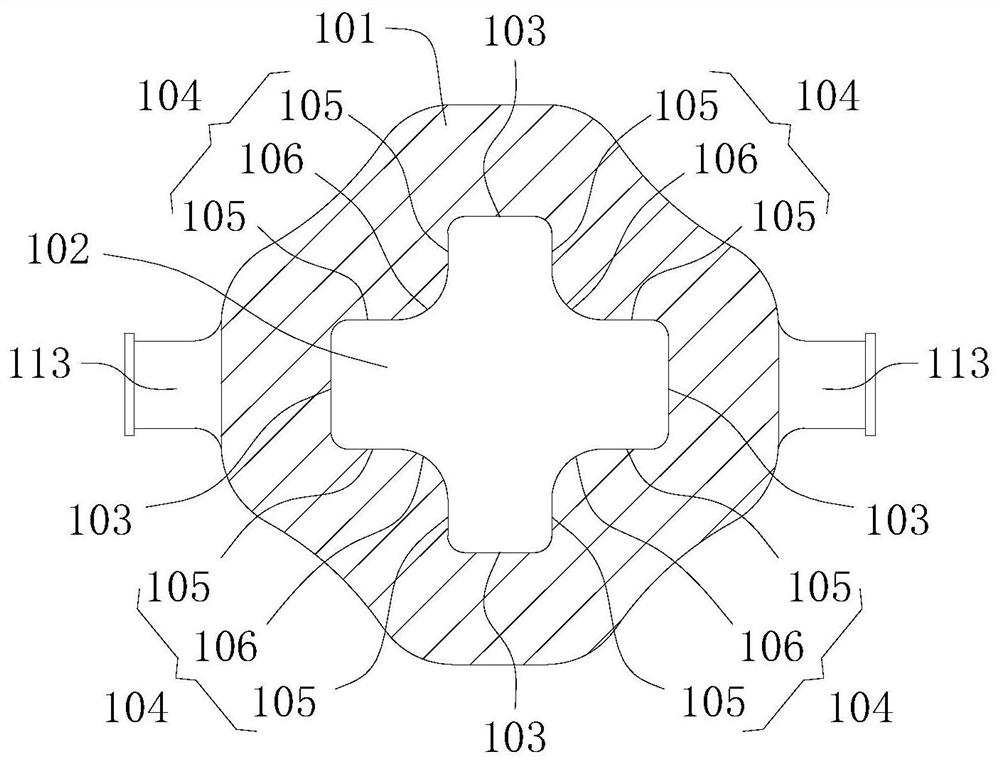

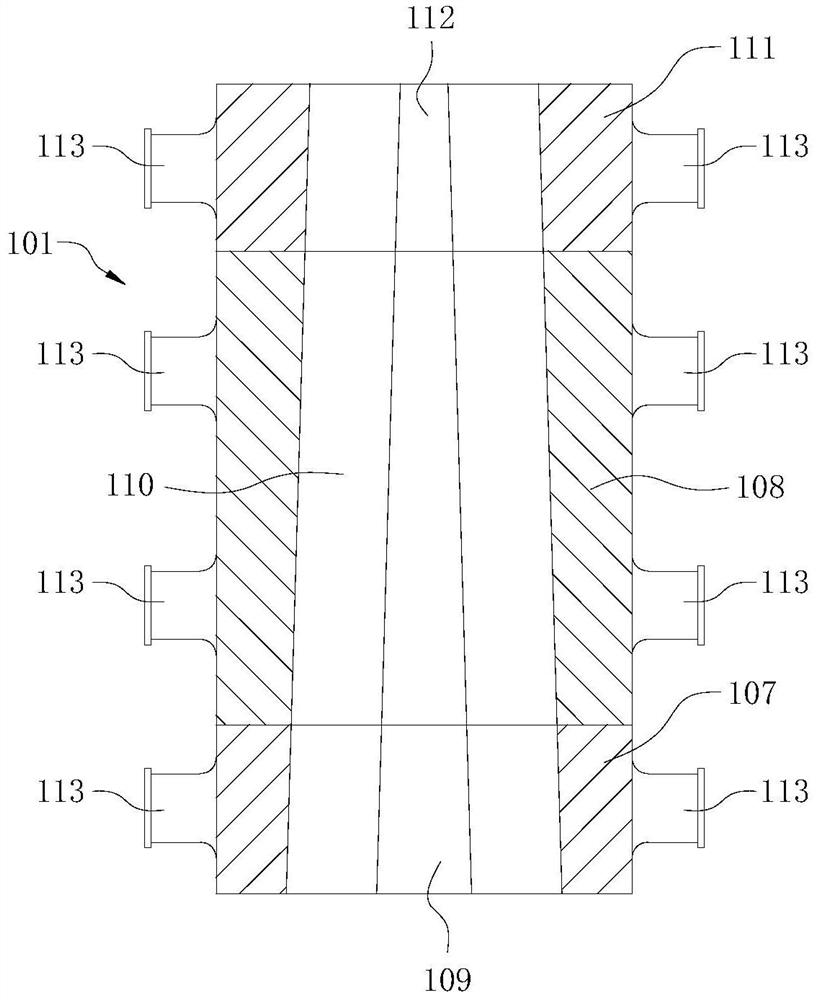

[0020] figure 1 It is a structural schematic diagram of the steel ingot mold provided by the embodiment of the present invention; figure 2 yes figure 1 Middle A-A sectional view.

[0021] see figure 1 , figure 2 The steel ingot mold provided by the embodiment of the present invention includes a steel ingot mold body 101; the steel ingot mold body 101 has a pouring cavity 102 vertically arranged and passing through the steel ingot mold body 101; the pouring cavity 102 is small at the top and large at the bottom Or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com