Rural black ash sewage treatment system and technological process

A sewage treatment, black ash technology, applied in gray water treatment, toilet black water treatment, biological water/sewage treatment, etc., can solve the problems of inconvenient practical use, inconvenient sand cleaning, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

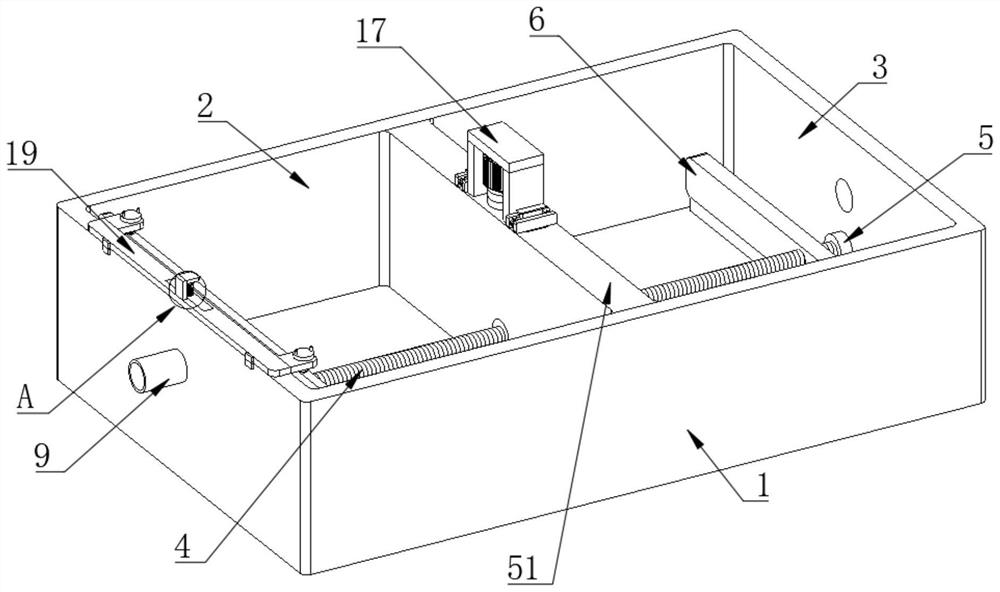

[0041] Embodiment one, by Figure 1 to Figure 7 Given, the present invention comprises three lattice septic tanks, grid sedimentation tank and sand settling equipment, and sand settling equipment comprises sand settling box 1, and clapboard 51 is arranged in the sand settling box 1, and the both sides of divider plate 51 are ash respectively. The water tank 2 and the black water tank 3 are provided with a two-way screw rod 4 in the sand settling box 1, and a control chamber 8 is provided in the partition 51, and the two ends of the two-way screw screw 4 and the inner wall of the sand settling box 1 pass through the first bearing 5 Connection, the gray water tank 2 and the black water tank 3 are equipped with a first movable plate 6, the bottom of the first movable plate 6 is provided with a number of flexible scrapers 7, and the two-way screw rod 4 runs through the two first movable plates 6 and the partition 51 The connection mode between the bidirectional screw rod 4 and the...

Embodiment 2

[0044] Embodiment two, on the basis of embodiment one, by Figure 4 , Figure 5 , Image 6 and Figure 7 Given, the anti-off piece includes a card slot 23 opened on one side of the side plate 18, and the side of the two side plates 18 away from each other is provided with a second fixing plate 24, and the second fixing plate 24 is fixedly connected to the partition plate 51, The side of the second fixed plate 24 away from the side plate 18 is provided with a second movable plate 25, and the side of the second movable plate 25 close to the second fixed plate 24 is fixedly connected with a limiting plate 26, and the limiting plate 26 runs through the second fixed plate 24, and one end of the limiting plate 26 is located in the slot 23, the second movable plate 25 and the second fixed plate 24 are connected by a number of tension springs 27, and the limiting plate 26 is provided with a limiting plate that matches the partition plate 51 Clip, the limit clip includes the first t...

Embodiment 3

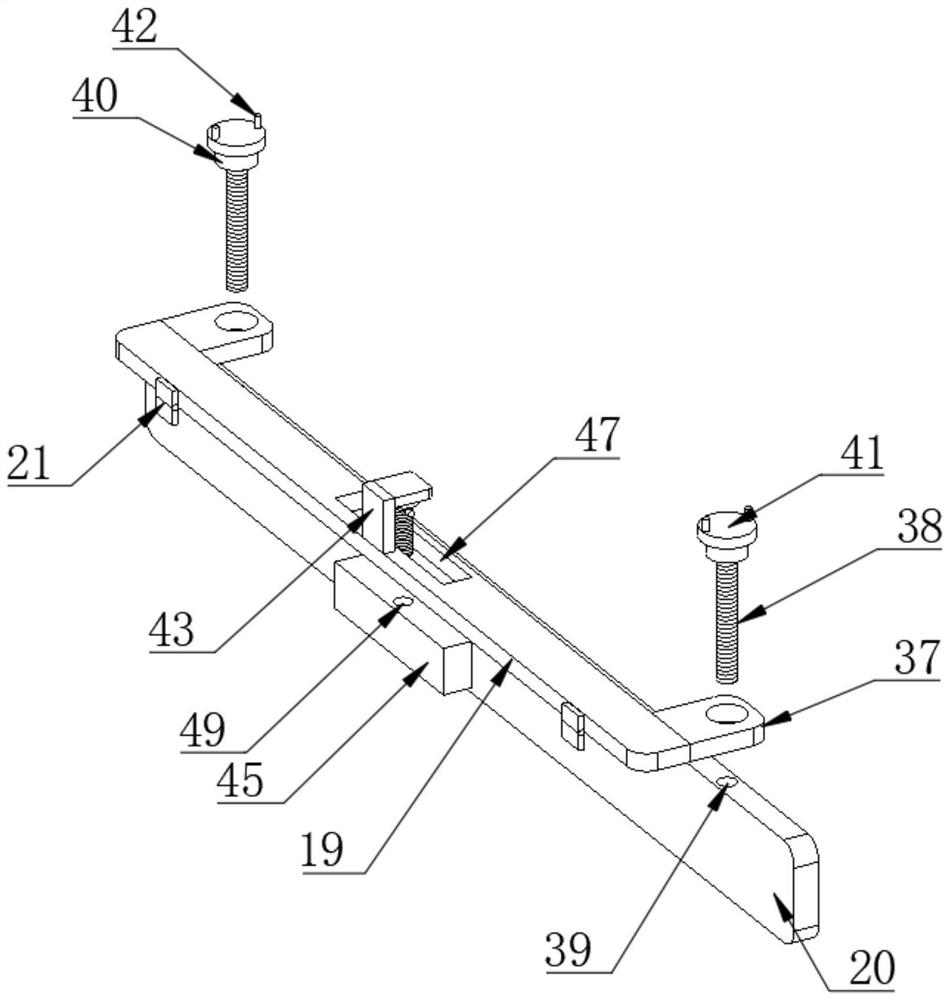

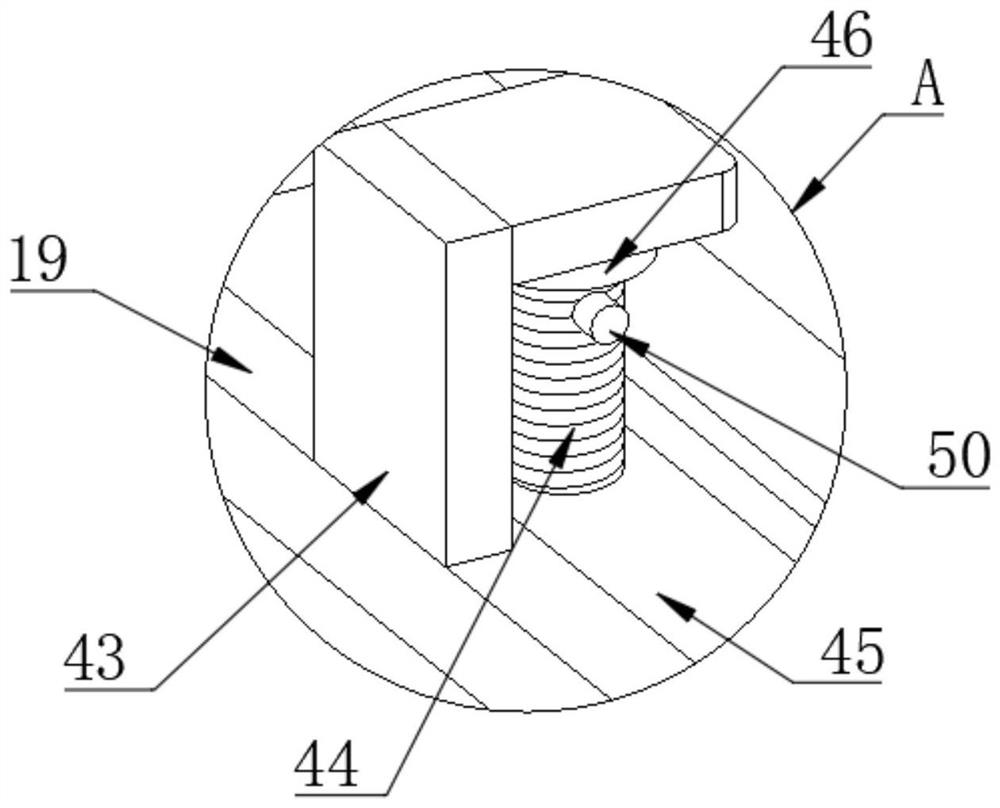

[0046] Embodiment three, on the basis of embodiment one, by figure 1 and figure 2 Given, the oil trap regulator includes two third fixing plates 37 arranged on one side of the rotating cover plate 19, one side of the third fixing plate 37 is fixedly connected with one side of the rotating cover plate 19, and one side of the third fixing plate 37 The top is provided with a third fixed disk 41, the bottom of the third fixed disk 41 is fixedly connected with the first screw mandrel 38, the first screw mandrel 38 runs through the third fixed plate 37, the penetration of the first screw mandrel 38 and the third fixed plate 37 The fifth bearing 40 is provided at the top of the oil separator 20, and two thread grooves 39 are opened on the top of the oil separator 20. The bottom end of the first screw rod 38 is located in the thread groove 39, and the top of the third fixed plate 41 is fixedly connected with two first handles. 42;

[0047] By driving the first handle 42 to rotate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com