A dual-element melting and casting explosive and its additive manufacturing process

A melting and casting explosive and dual-element technology, which is applied in the field of explosives, can solve the problems of many preparation process restrictions and the energy level of melting and casting explosives needs to be further improved, and achieve the effect of simple preparation process, low explosive sensitivity and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The present embodiment provides a dual-element molten-cast explosive, which is an inner and outer coaxial charge, the inner-layer charge adopts a TNT-based high-energy explosive, and the outer-layer charge adopts a DNAN-based high-security explosive;

[0047] The mass ratio of the inner charge to the outer charge is 1:1.

[0048] TNT-based high-energy explosive, in mass percentage, consists of the following raw materials: 18% of TNT, 80% of HMX, and 2% of microcrystalline wax;

[0049] The DNAN-based high-security explosive, in terms of mass percentage, is composed of the following raw materials: DNAN is 18%, HMX is 80%, and microcrystalline wax is 2%.

[0050] The additive manufacturing process of the dual-element molten-cast explosive in this embodiment is to obtain the inner and outer layers of the dual-element molten-cast explosive molding grain by stacking layer by layer through an additive manufacturing molding process. Specifically, the process includes the foll...

Embodiment 2

[0064] The present embodiment provides a dual-element molten-cast explosive, which is an inner and outer coaxial charge, the inner charge adopts a TNT-based high-energy explosive, and the outer-layer charge adopts a DNAN-based high-security explosive;

[0065] The mass ratio of the inner charge to the outer charge is 1:1.

[0066] TNT-based high-energy explosive, in mass percentage, is composed of the following raw materials: 16% of TNT, 83% of HMX, and 1% of microcrystalline wax;

[0067] The DNAN-based high-security explosive, in terms of mass percentage, is composed of the following raw materials: DNAN is 20%, HMX is 78%, and microcrystalline wax is 2%.

[0068] The additive preparation process of the binary molten-cast explosive in this embodiment is basically the same as that of Example 1, and the only difference is that the formula ratio of the above-mentioned binary molten-cast explosive is different.

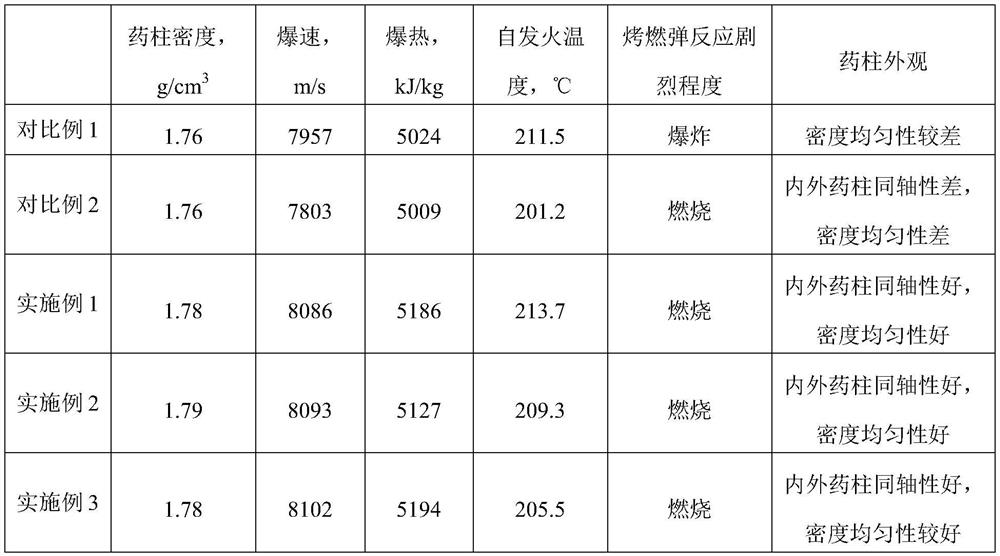

[0069] See Table 1 for the performance test results of this embodi...

Embodiment 3

[0071] The present embodiment provides a dual-element molten-cast explosive, which is an inner and outer coaxial charge, the inner charge adopts a TNT-based high-energy explosive, and the outer-layer charge adopts a DNAN-based high-security explosive;

[0072] The mass ratio of the inner charge to the outer charge is 1:1.

[0073] TNT-based high-energy explosive, in mass percentage, is composed of the following raw materials: 20% of TNT, 78% of HMX, and 2% of microcrystalline wax;

[0074] The DNAN-based high-security explosive, in terms of mass percentage, is composed of the following raw materials: DNAN is 15%, HMX is 83%, and microcrystalline wax is 2%.

[0075] The additive preparation process of the binary molten-cast explosive in this embodiment is basically the same as that of Example 1, and the only difference is that the formula ratio of the above-mentioned binary molten-cast explosive is different.

[0076] See Table 1 for the performance test results of this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com