Preparation method of waterproof and cool warp-knitted fabric and warp knitted fabric prepared by method

A waterproof, cool and functional technology, applied in warp knitting, textile material processing, rayon manufacturing, etc., can solve problems such as difficulty in simultaneous use, difficulty in dyeing polyethylene fibers, and large differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

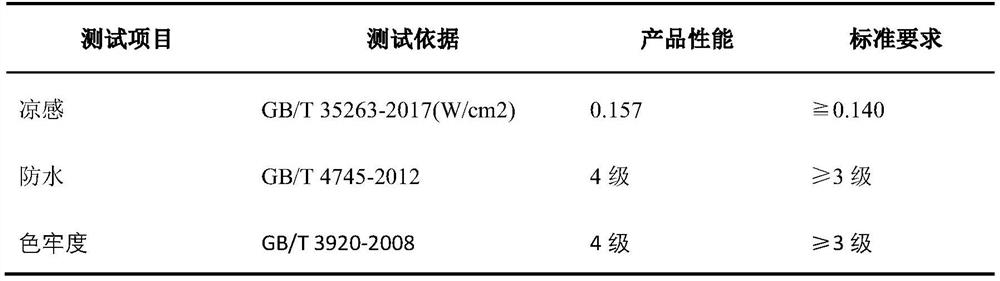

Embodiment 1

[0032] Polyethylene fiber modification: dyeable polyethylene fiber modified by montmorillonite. The preparation method includes mixing montmorillonite and polyethylene powder to prepare montmorillonite modified polyethylene polymer material. In the first step of premixing, a certain amount of montmorillonite and polyethylene powder are mixed in a premixer for 20 minutes, and the speed of the premixer is 300r / min.

[0033] The mixed powder is realized by twin-screw extrusion process, the processing temperature is 135-155°C, and the montmorillonite modified polyethylene chips are prepared, and the polyethylene fiber is prepared by melt spinning, wherein the content of montmorillonite in the polyethylene fiber is 1.2% .

[0034] 20 parts by weight of polyethylene fiber 75 / 72 DTY and 80 parts by weight of ordinary polyester 75 / 144 DTY are used as raw materials for the face thread, the middle thread is made of 50D FDY ordinary polyester, and the bottom thread is made of ordinary po...

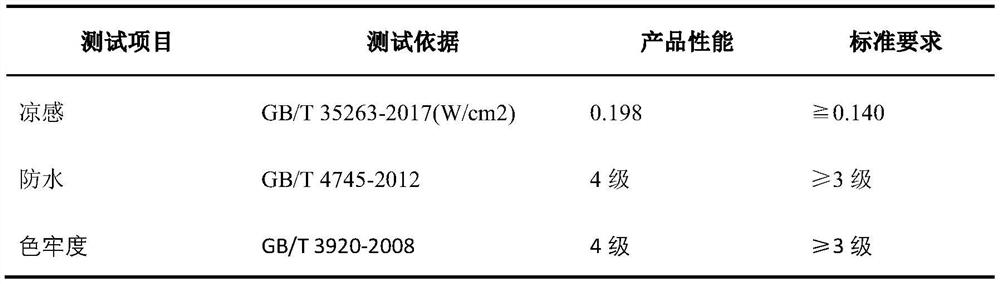

Embodiment 2

[0044] Polyethylene fiber modification: dyeable polyethylene fiber modified by montmorillonite. The preparation method includes mixing montmorillonite and polyethylene powder to prepare montmorillonite modified polyethylene polymer material. In the first step of premixing, a certain amount of montmorillonite and polyethylene powder are mixed in a premixer for 20 minutes, and the speed of the premixer is 300r / min.

[0045] The mixed powder is realized by twin-screw extrusion process, the processing temperature is 135-155°C, and the montmorillonite modified polyethylene chips are prepared, and the polyethylene fiber is prepared by melt spinning, wherein the content of montmorillonite in the polyethylene fiber is 1.2% .

[0046] 40 parts by weight of polyethylene fiber 75 / 72 DTY and 60 parts by weight of ordinary polyester 75 / 144 DTY are used as raw materials for the face yarn, the middle yarn is made of 50D FDY ordinary polyester, and the bottom yarn is made of ordinary polyeste...

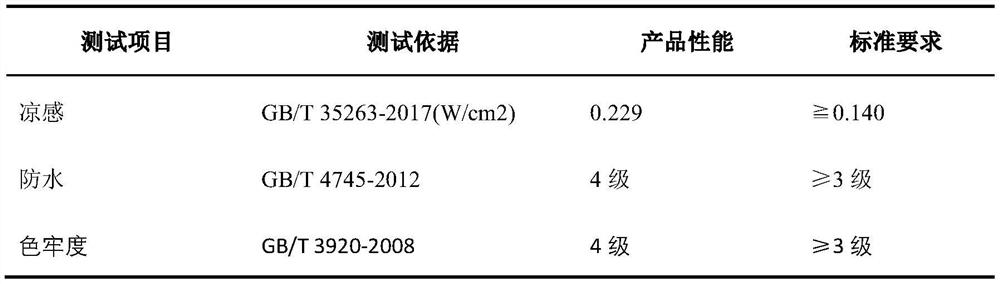

Embodiment 3

[0056] Polyethylene fiber modification: dyeable polyethylene fiber modified by montmorillonite. The preparation method includes mixing montmorillonite and polyethylene powder to prepare montmorillonite modified polyethylene polymer material. In the first step of premixing, a certain amount of montmorillonite and polyethylene powder are mixed in a premixer for 20 minutes, and the speed of the premixer is 300r / min.

[0057] The mixed powder is realized by twin-screw extrusion process, the processing temperature is 135-155°C, and the montmorillonite modified polyethylene chips are prepared, and the polyethylene fiber is prepared by melt spinning, wherein the content of montmorillonite in the polyethylene fiber is 1.2% .

[0058] 60 parts by weight of polyethylene fiber 75 / 72 DTY and 40 parts by weight of ordinary polyester 75 / 144 DTY are used as raw materials for the face yarn, the middle yarn is made of 50D FDY ordinary polyester, and the bottom yarn is made of ordinary polyeste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com