Threaded steel bar tensioning and anchoring device and construction method thereof

A threaded steel bar and anchoring device technology, which is applied in the processing of building materials, construction, building reinforcements, etc., can solve the problems of stress concentration, difficult construction, high cost, etc., and achieve reasonable overall force, low construction conditions and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

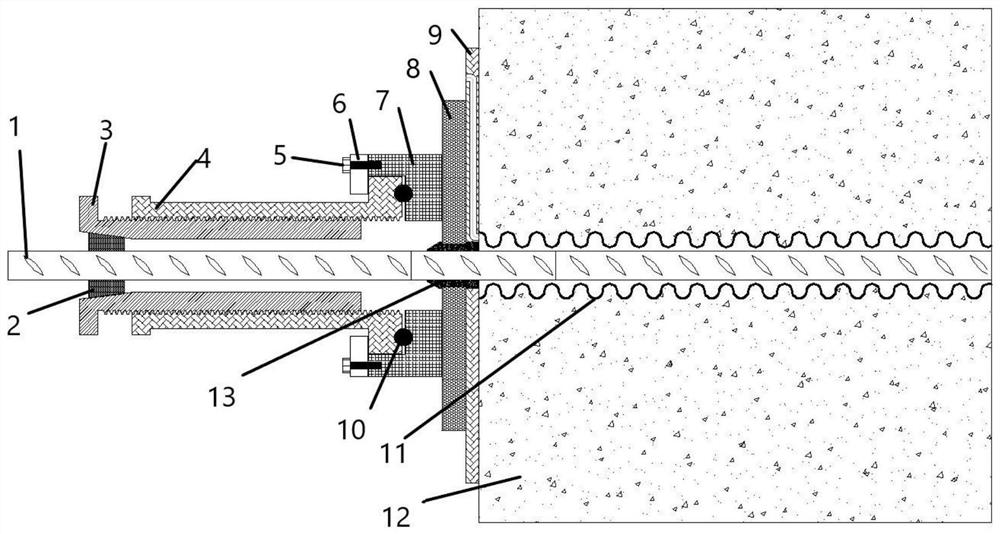

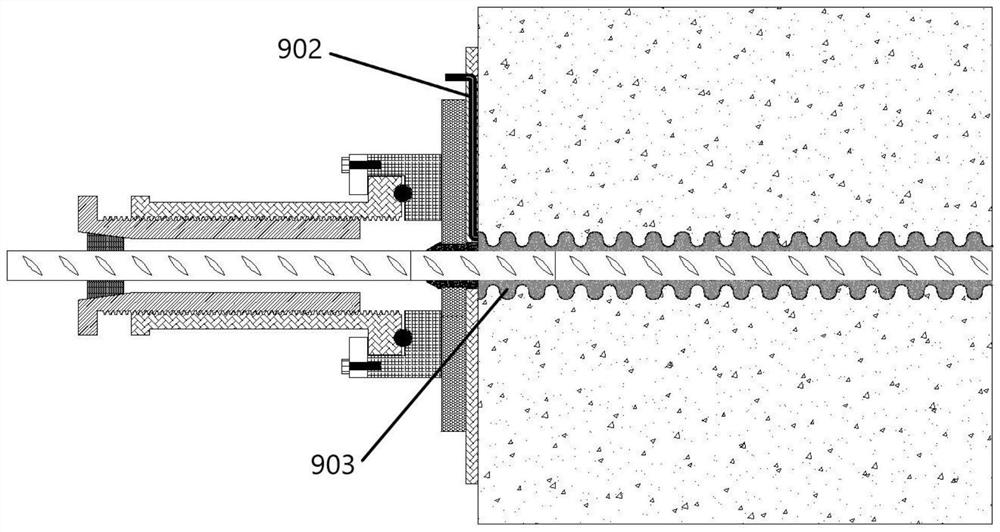

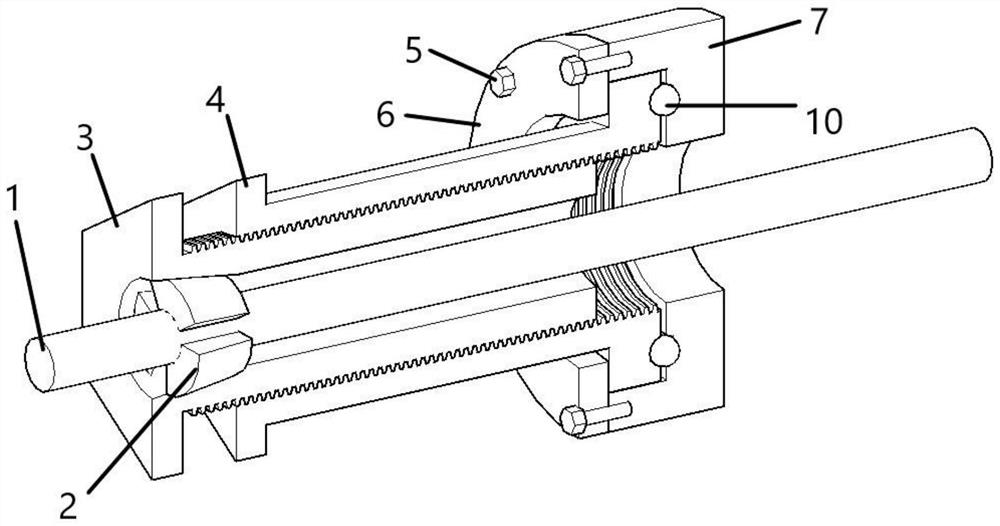

[0047] The tensioning and anchoring device for threaded steel bars described in this embodiment mainly includes a steel bar clip 2, an anchor head 3, a rotary cylinder 4, a base 7, a steel backing plate 8, a rubber backing plate 9 and a rubber plug 13, when the threaded steel bar is stretched At 1 o'clock, the anchor head 3 and the rotating cylinder 4 rotate relative to each other, and at this time the anchor head 3 pushes out to the left, driving the steel bar clip 2 and the threaded steel bar 1 to move to the left, thereby stretching the threaded steel bar 1. The reinforcement clip 2 is a split structure, including a plurality of clip units arranged around the threaded steel bar 1, and the section of the clip unit is a right-angled trapezoidal structure. The anchor head 3 is a hollow tubular structure, the outer end is provided with an anchor head hexagonal head for the knob, and the outer end of the anchor head 3 is provided with an inverted conical cavity structure 302 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com