Evaporative cooling system and operation method thereof

A technology for evaporative cooling and absorption of solutions, which is applied in air conditioning systems, heating methods, household heating, etc., can solve problems such as high energy consumption and cost, effective utilization, and lack of economically feasible utilization technologies, so as to reduce energy consumption, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

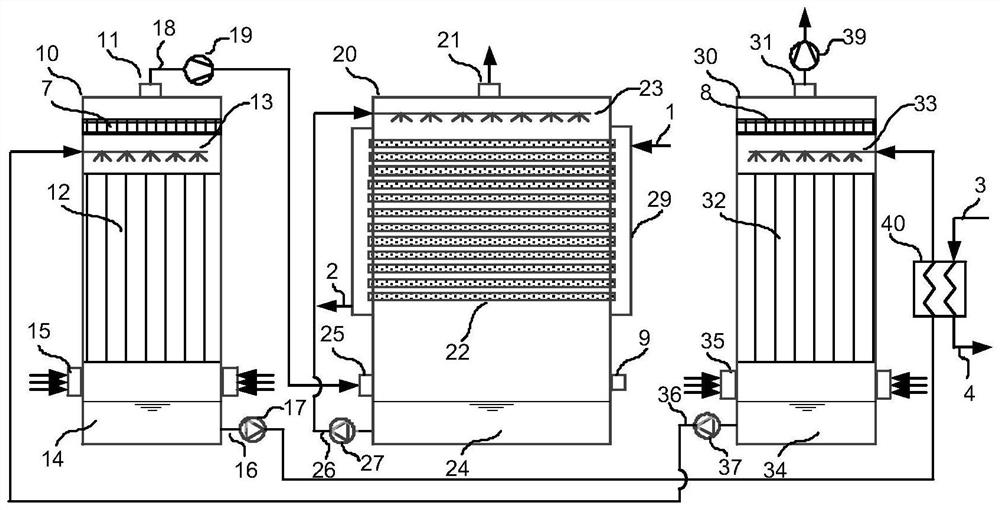

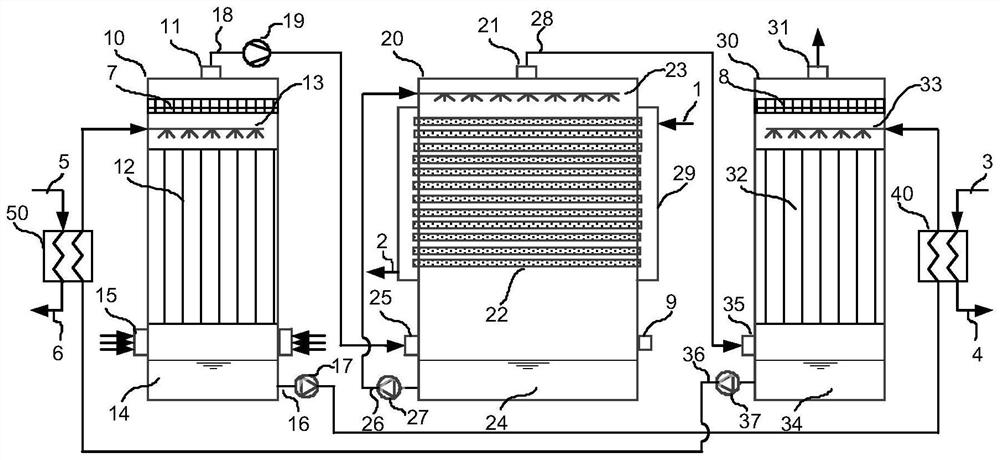

[0126] This embodiment provides an evaporative cooling system, see image 3 , the material of the air dehumidification tower 10 is ordinary carbon steel, its length and width are 4.5m, and the total height is 3.3m. The concentrated absorption solution spray mechanism 13 is composed of a spray main pipe and a nozzle. The height of the layer 12 is 2.5m, filled with polypropylene plastic Pall rings, the bottom of the air dehumidification tower 10 is used as a dilute absorption solution collection box 14, its height is 0.3m, and the first liquid collector 7 is composed of multi-layer 304 stainless steel wire mesh , its height is 0.1m; evaporative cooling device 20 is common carbon steel, its length and width are 4.5m, total height 3.3m, the heat transfer tube of heat transfer tube bundle 22 is oval heat transfer tube, and its material is common carbon steel, The absorption solution regeneration tower 30 is made of ordinary carbon steel, its length and width are 4.5m, and its total...

Embodiment 2

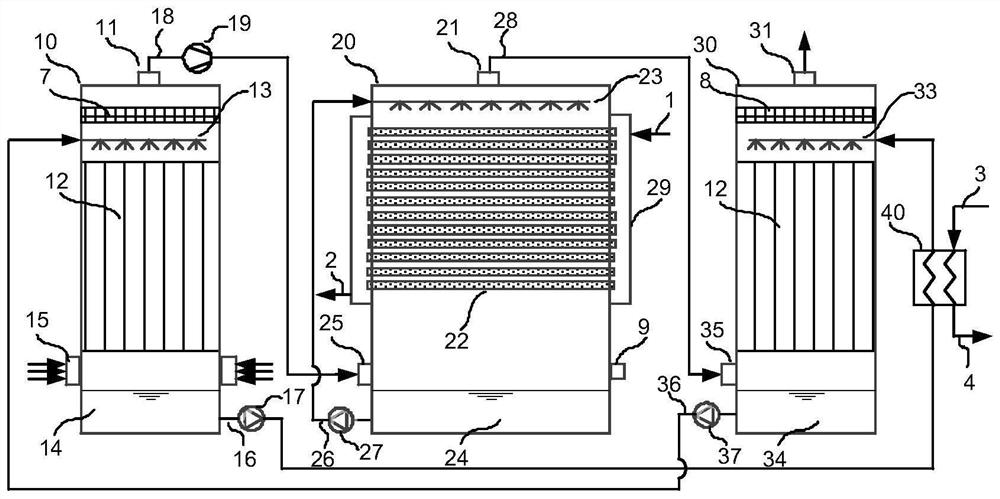

[0132] This embodiment provides an evaporative cooling system, see Figure 8 , The difference between this embodiment and Embodiment 1 is that the total height of the evaporative cooling device 20 is 4.4m, wherein the third packing layer 42 has a height of 1m and is filled with polypropylene plastic Pall rings; the second air fan 39 adopts a stainless steel shaft Flow fan.

[0133] For the operating method of the evaporative cooling system of this embodiment, see Figure 8 , including the following steps:

[0134] S1. Air dehumidification process: In the air dehumidification tower 10, the air that enters through the first air inlet 15 is mixed with the concentrated absorption solution sprayed by the concentrated absorption solution spraying device 13 in the air dehumidification tower 10. Countercurrent contact is carried out in the first packing layer 12 mentioned above, and the described concentrated absorption solution absorbs the moisture in the air to form a dilute absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com