Process for solving air holes and shrinkage porosity of top partition plate of double-flow-channel volute

A dual-channel, volute technology, applied in manufacturing tools, metal processing equipment, casting and molding equipment, etc., can solve the problems of pore shrinkage defects and complexity of the flow channel baffle plate, improve the process yield and prolong the gas storage time. and space, the effect of solving positional defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. Such as Figure 1-2 Shown: a dual-channel volute top diaphragm air hole and shrinkage solution process, including the following steps:

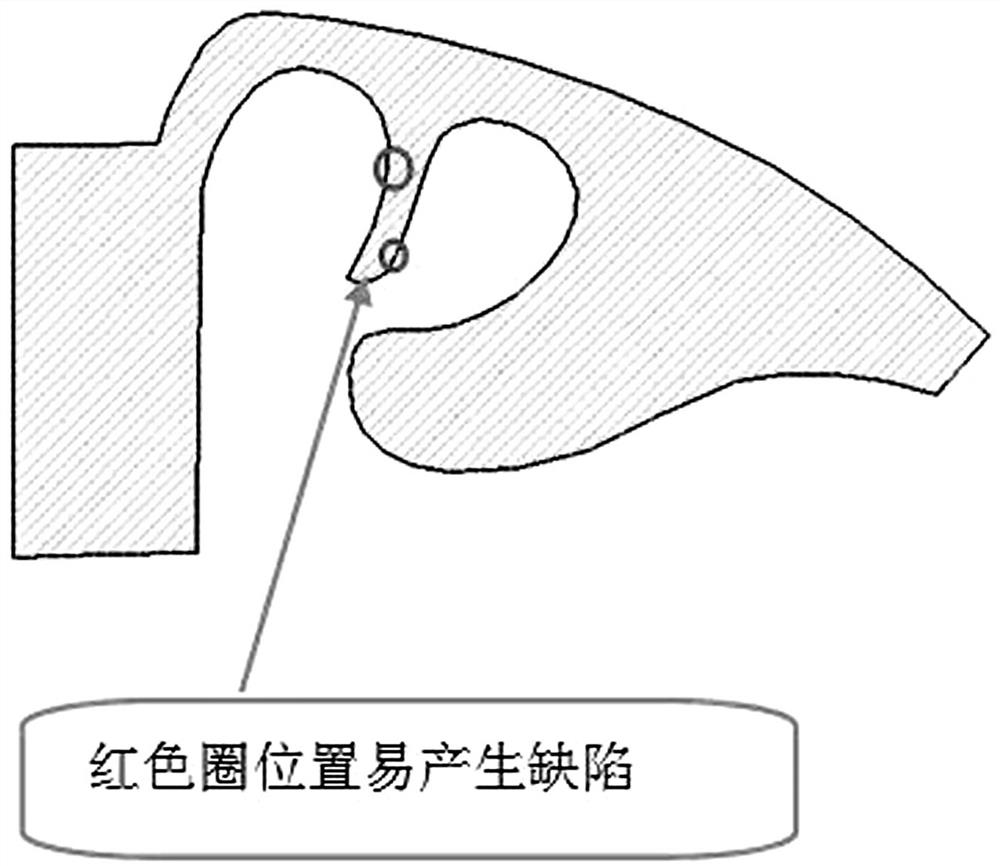

[0014] Step 1: Process Design: Reference figure 1 , determine the parting scheme according to the product structure, design the process according to the parting plan and conduct casting simulation analysis, and find out the position where the defect is most likely to appear on the top of the double-channel volute according to the results; generally, it is most likely to appear on the top of the product vortex;

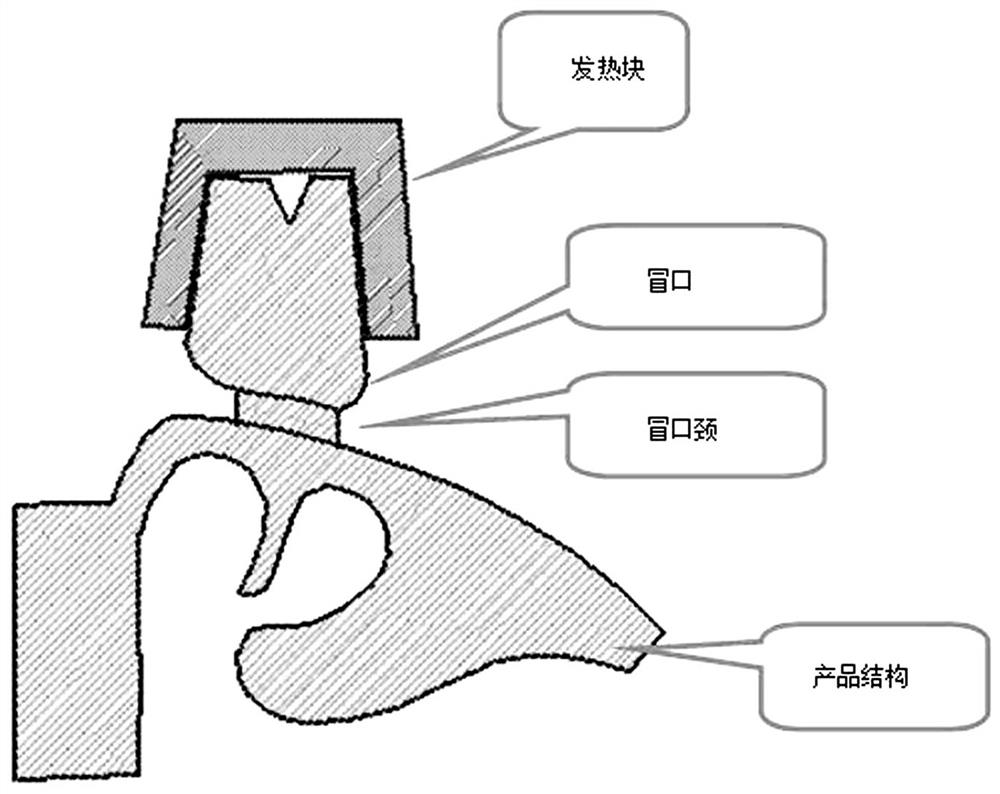

[0015] Step 2: Plan determination: reference figure 2 , design the riser neck process boss at the position where the defect is found, design the riser on the upper part of the riser neck boss, add a heating block outside the riser, and delay the feed and exhaust of the riser to the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com