Automatic production integrated device for safety air bag and production method

An integrated device and airbag technology, which is applied in the field of automatic production integrated devices for airbags, can solve the problems of lack of product process parameters, effective control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

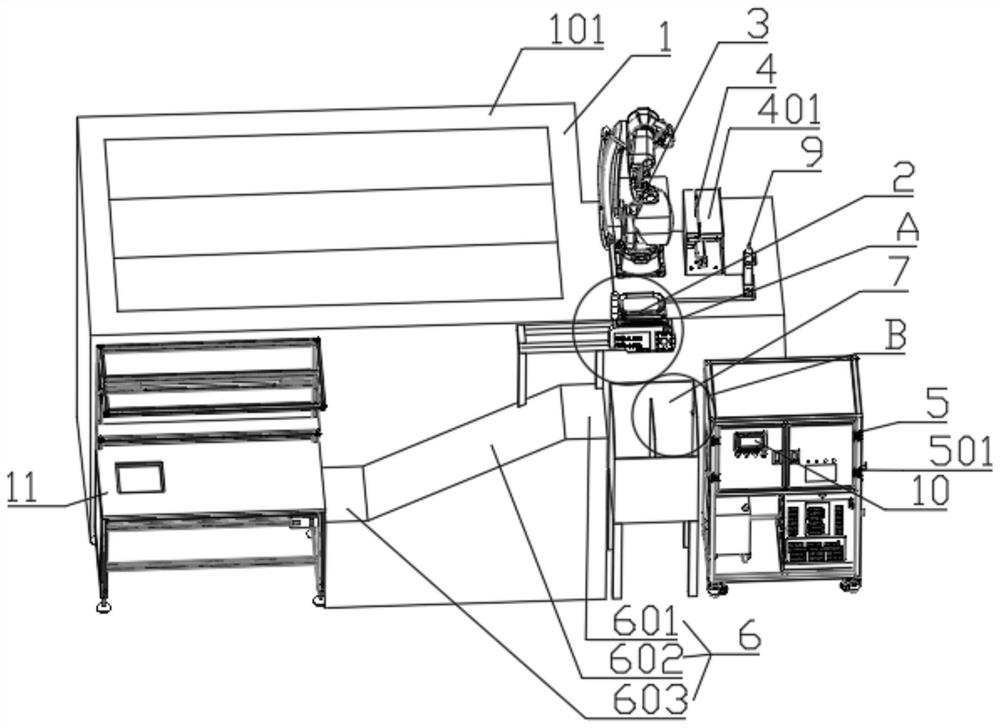

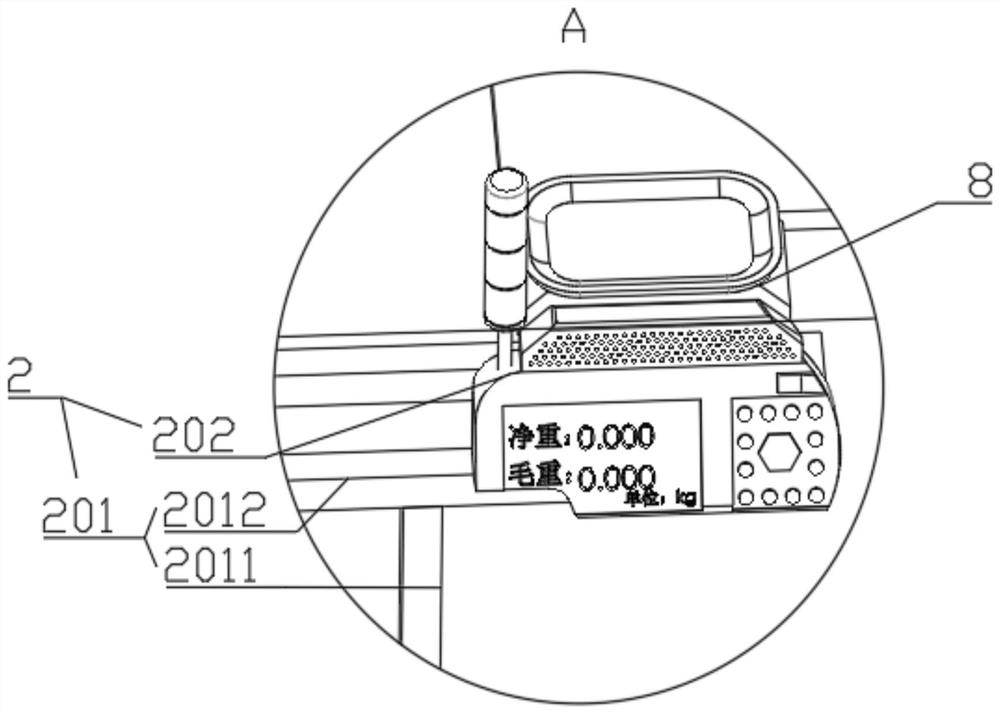

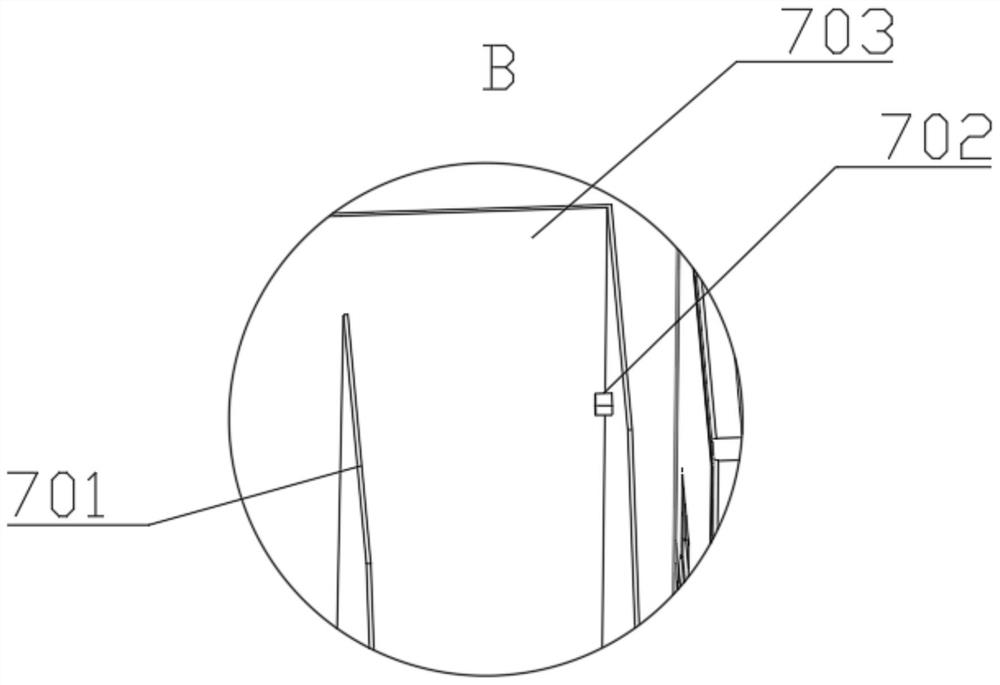

[0028] Such as Figures 1 to 4 As shown, the integrated device for automatic production of airbags, which includes injection molding module 1, weighing module 2, manipulator 3, barcode printing module 4, electronic control module 5, unloading flow line 6, heat gun 9 and defective product box 7 . Injection molding module 1 comprises injection molding machine 101; Unloading flow line 6 is arranged on the side of injection molding machine 101 along the width direction of injection molding machine 101; Unloading flow line 6 comprises first horizontal conveyer belt 601, inclined section conveyer belt 602 and the second according to conveying direction successively Two horizontal conveyor belts 603 , the first horizontal conveyor belt 601 is higher than the second horizontal conveyor belt 603 , one end of the inclined conveyor belt 602 is connected to the first horizontal conveyor belt 601 , and the other end is connected to the second horizontal conveyor belt 603 . The first horiz...

Embodiment 2

[0035] The present invention also includes a production method of an automatic production integrated device for airbags, which includes the following steps. First, the first five molds produced by the injection molding module 1 are put into the defective product box 7 through the manipulator 3 after each start-up or shutdown restart. Second, starting from the sixth mold, the manipulator 3 grips the product to the heat gun 9 to remove the burr; then, the manipulator 3 grips the product after removing the burr to the barcode printing module 4 to print and paste the two-dimensional code; then, the manipulator 3. Clamp the product after printing the QR code to the weighing module 2 for weighing; finally, the manipulator 3 clamps the weighed and qualified product to the unloading flow line 6, and is conveyed by the unloading flow line 6 The product arrives at 11 places on the workbench, and the manipulator 3 clamps the unqualified product of the weight after weighing into the defect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com