Wrinkling processing equipment for producing masking base paper

A technology of textured paper and base paper, applied in papermaking, paper machine, textile and papermaking, etc., to achieve the effect of improving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

[0046] In order to solve the technical problem that the existing wrinkling scraper needs to be shut down for a long time to replace the blade, such as Figure 4 As shown, the following preferred technical solutions are provided:

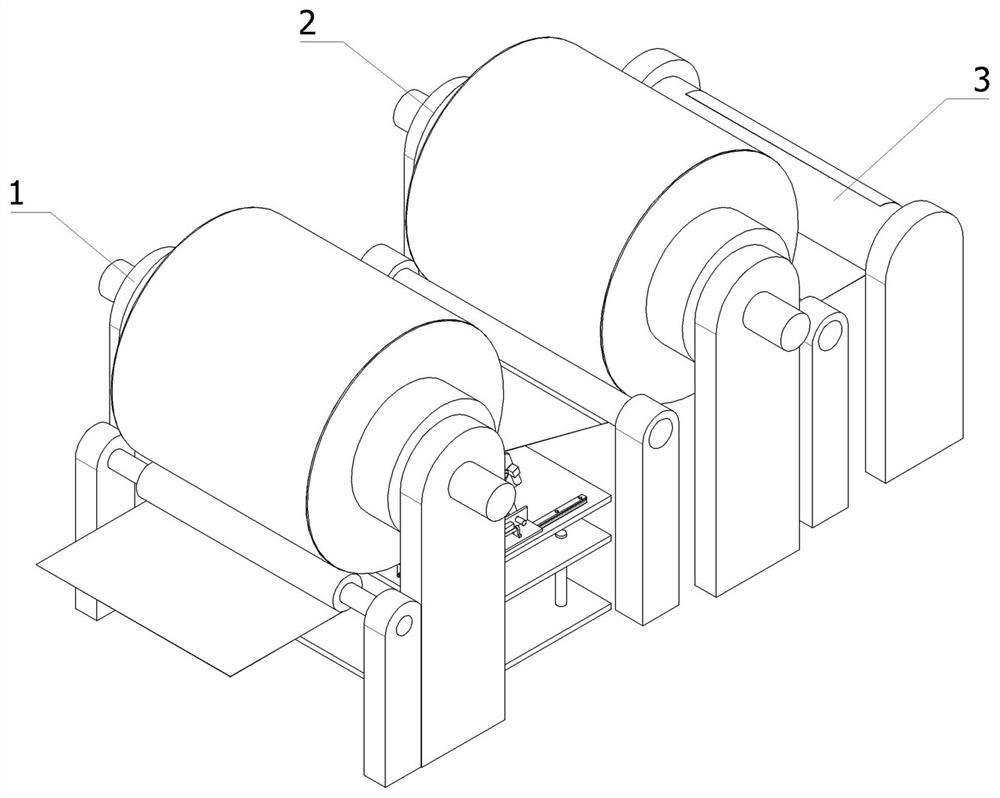

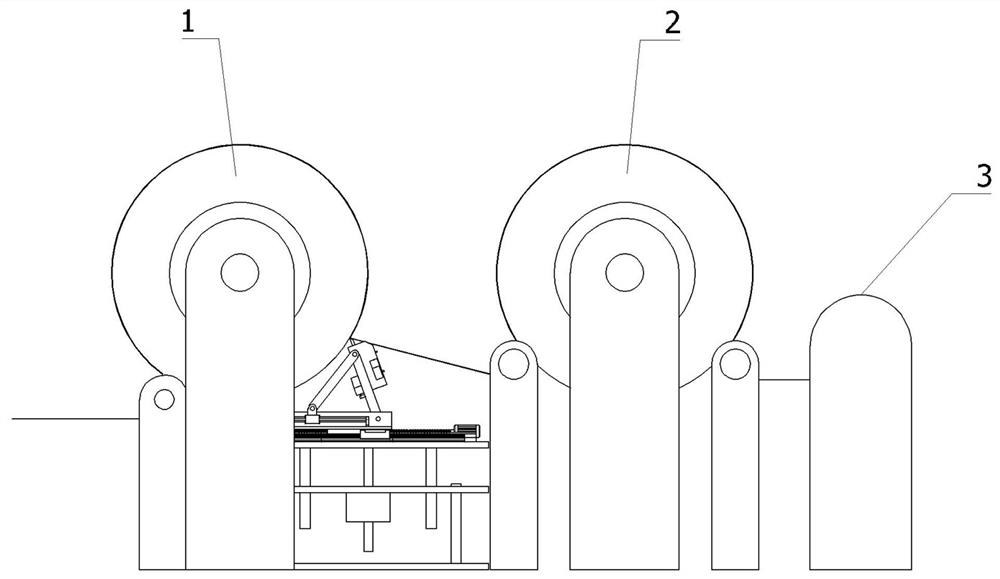

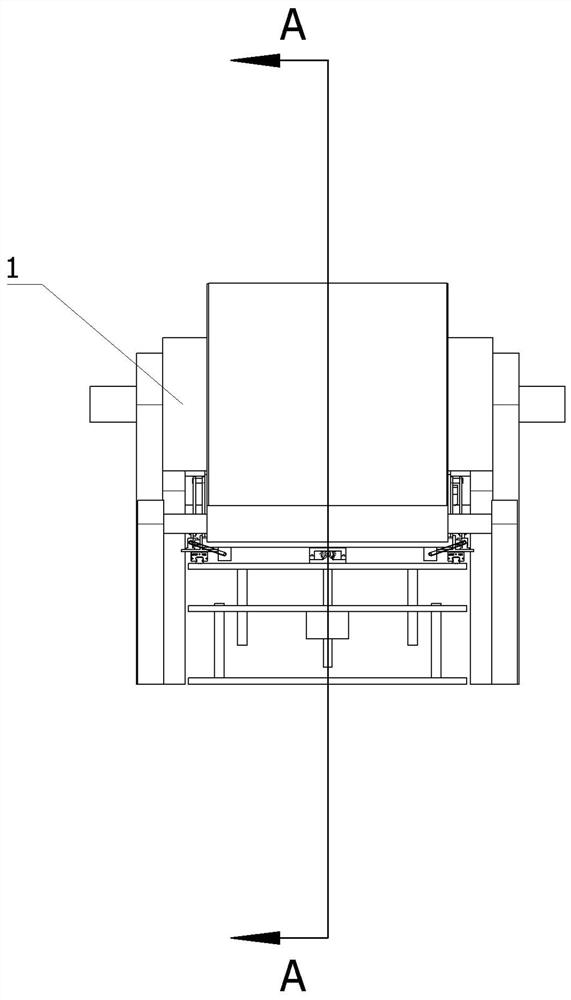

[0047] A crepe processing equipment for the production of textured base paper, comprising a first drying cylinder 1, a second drying cylinder 2, a winding roller 3 and a creping scraper assembly, the first drying cylinder 1, the second drying cylinder 2 and a winding cylinder Rollers 3 are placed coaxially and side by side in sequence; the creping scraper assembly includes,

[0048] The scraper clamp 4 is axially arranged at the bottom of the center line of the water surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com