Rod piece type column cap

A technology of column caps and rods, applied in the field of floor structure, can solve the problem of increasing column caps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

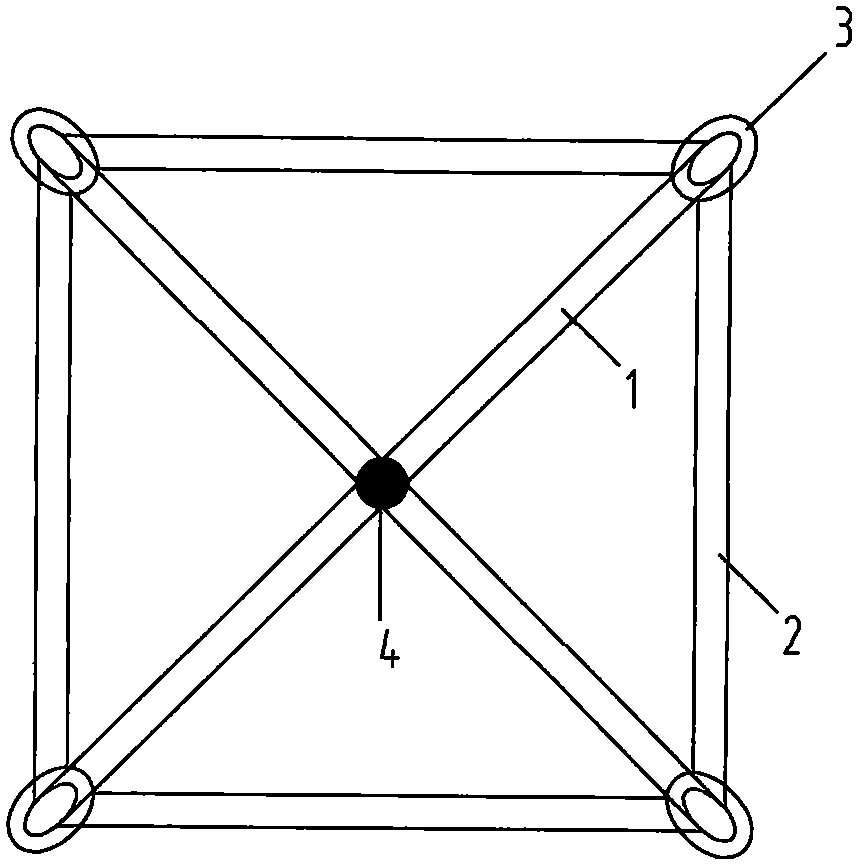

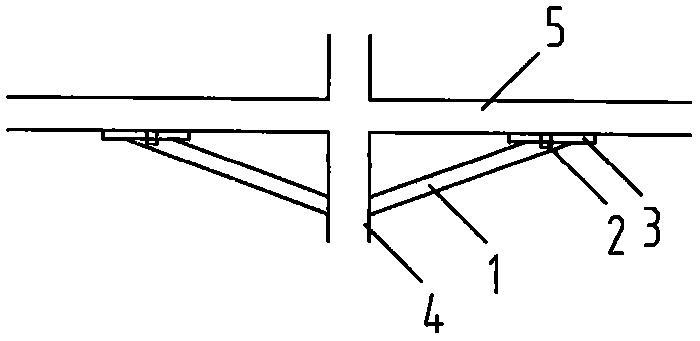

[0028] 1. The basic rod-type column cap is used for beamless floors:

[0029] Column net is the multi-storey shopping mall of 8m, reinforced concrete beamless floor, D600mm column, adopts the bar type column cap of basic type that the present invention provides, and horizontal bar (2) is centered on column (4), is located at square Around the column (4) and under the floor (5); the lower ends of the four oblique rods (1) are connected to the column (4), and the upper ends are connected to the intersection of the square; a horizontal support plate (3) is arranged at the intersection. Among them, the horizontal rod (2) is a 150*50 rectangular square steel pipe, the oblique rod (1) is a D180*10 round steel pipe, and the horizontal supporting plate (3) is a 600*400mm oval steel plate; the length of the oblique rod (1) is 2m; the corresponding floor thickness is 150mm.

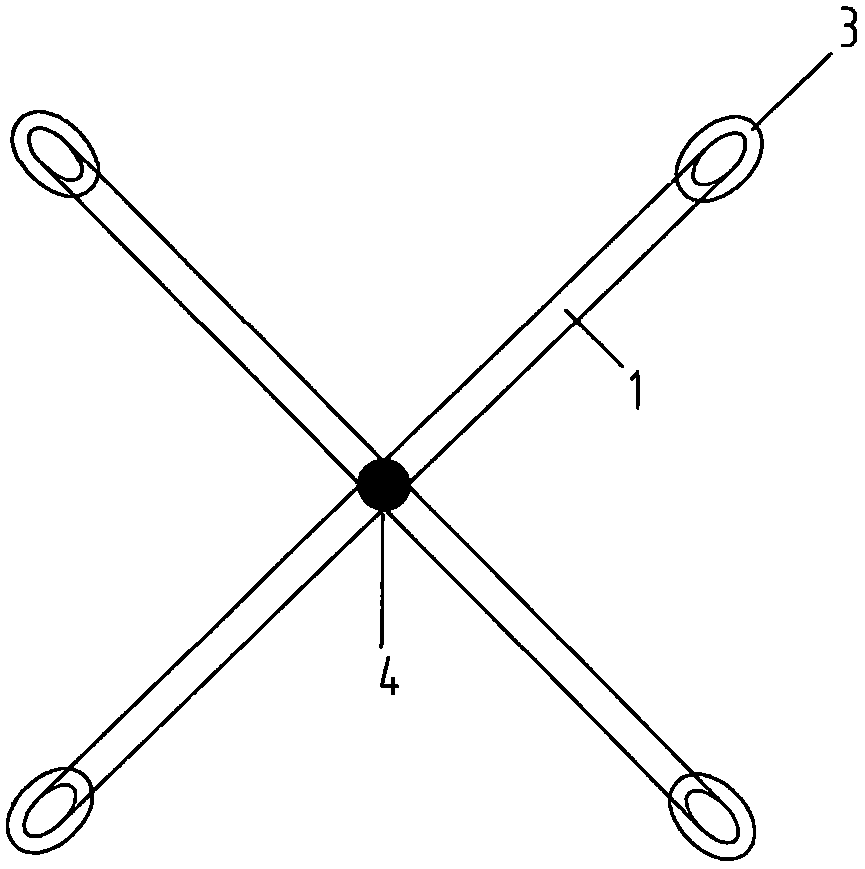

[0030] 2. Simplified rod-type column caps are used for wide flat beam frames:

[0031] It is still a multi-sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com