Fuel evaporation control system based on pilot-operated type fuel tank isolating valve

A technology of control system and isolation valve, which is applied in the direction of charging system, engine components, machine/engine, etc., can solve the problems of complex manufacturing process and high cost of honeycomb carbon rods, and achieve low manufacturing cost, excellent cost and low HC emission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

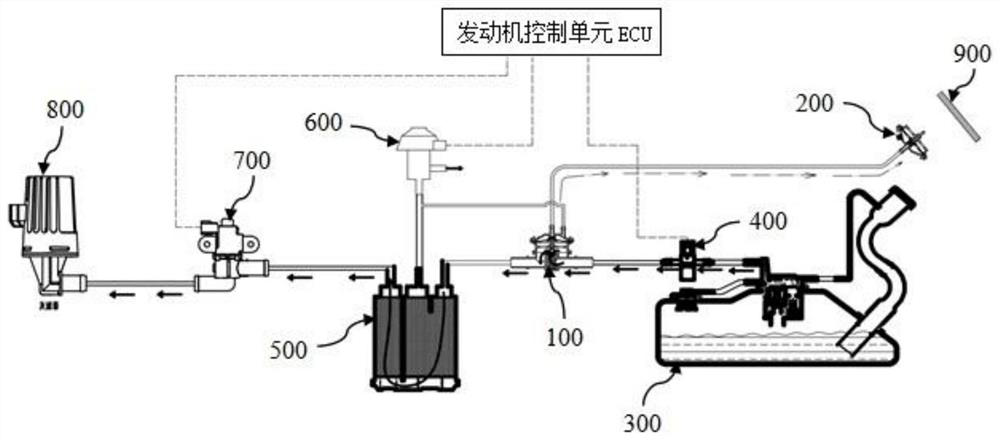

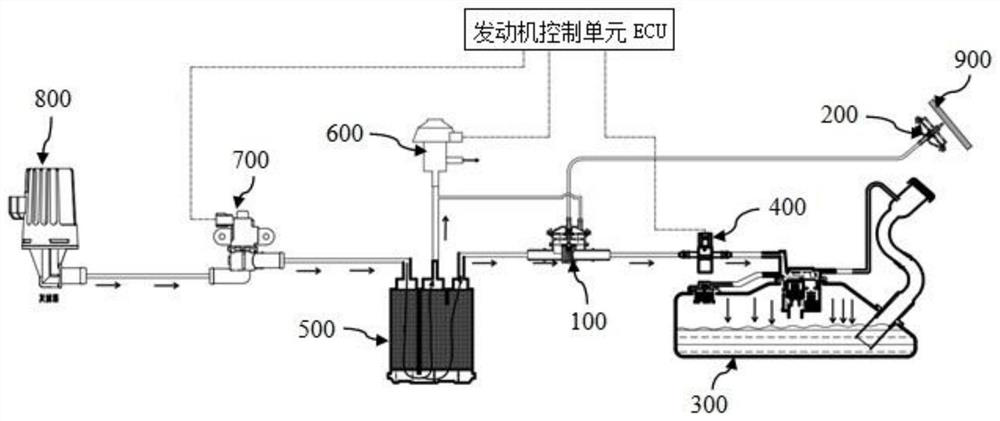

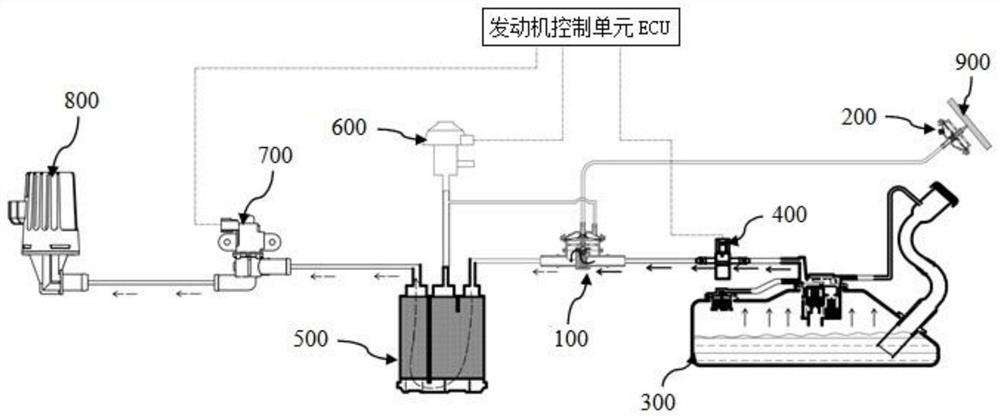

[0051] Such as Figure 1-4 As shown, the present invention provides a fuel evaporation control system based on a pilot-operated fuel tank isolation valve, including an engine control unit ECU, a desorption control valve 600, an ash filter 800 connected in sequence, a ventilation solenoid valve 700, a carbon canister 500, a pilot-operated The fuel tank isolation valve, the pressure detection module 400 , the fuel tank assembly 300 , the engine control unit controls the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com