Combined combustion-supporting air heating system of garbage incinerator

A waste incinerator and combustion-supporting air technology, applied in incinerators, lighting and heating equipment, combustion methods, etc., can solve the problem that the quality of heating steam cannot meet the design value, the temperature of combustion-supporting air cannot meet the requirements, and the air temperature cannot meet the requirements To achieve the effect of improving the convenience of operation, shortening the start-up time of the cold state furnace, and improving the balance of soda and water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

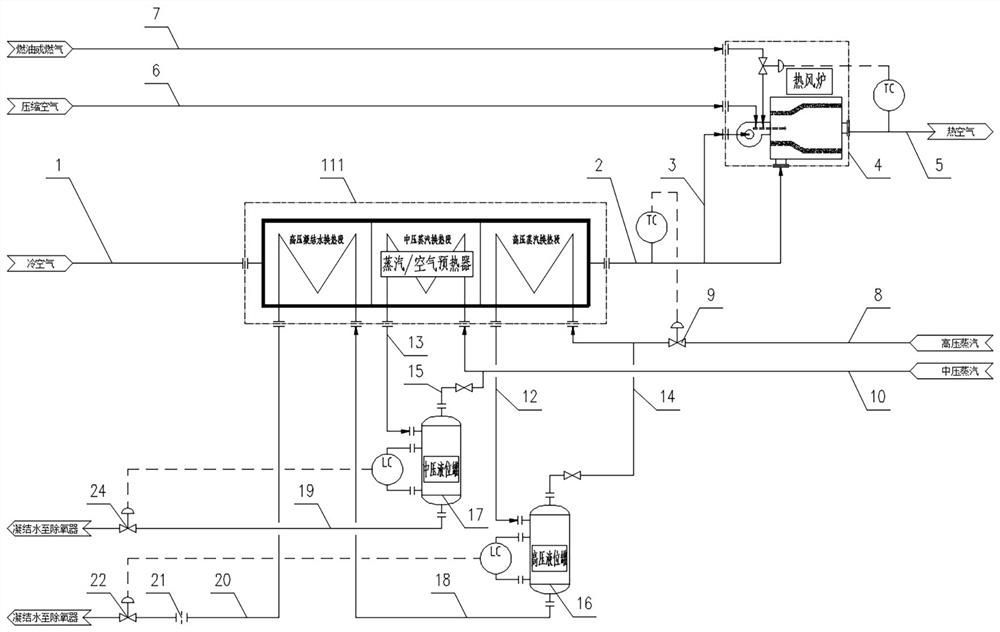

[0030] A combined combustion-supporting air heating system for a waste incinerator, such as figure 1 As shown, it includes a three-stage steam / air preheater 111. The three-stage steam / air preheater 111 includes several steam heat exchange sections. The heat exchange section and the high-pressure steam heat exchange section, the outer end of the high-pressure condensate heat exchange section is the air inlet side, and the outer end of the high-pressure steam heat exchange section is the air outlet side.

[0031] Such as figure 1 As shown, the air inlet side of the three-stage steam / air preheater 111 is connected to the cold air passage 1, and is used to heat the air flowing in from the cold air passage 1. The cold air passes through the high-pressure condensate heat exchange section, the medium-pressure steam heat exchange section and the high-pressure steam The hot section is gradually heated, and the air outlet side is connected to the first hot air passage 2, and the other ...

Embodiment 2

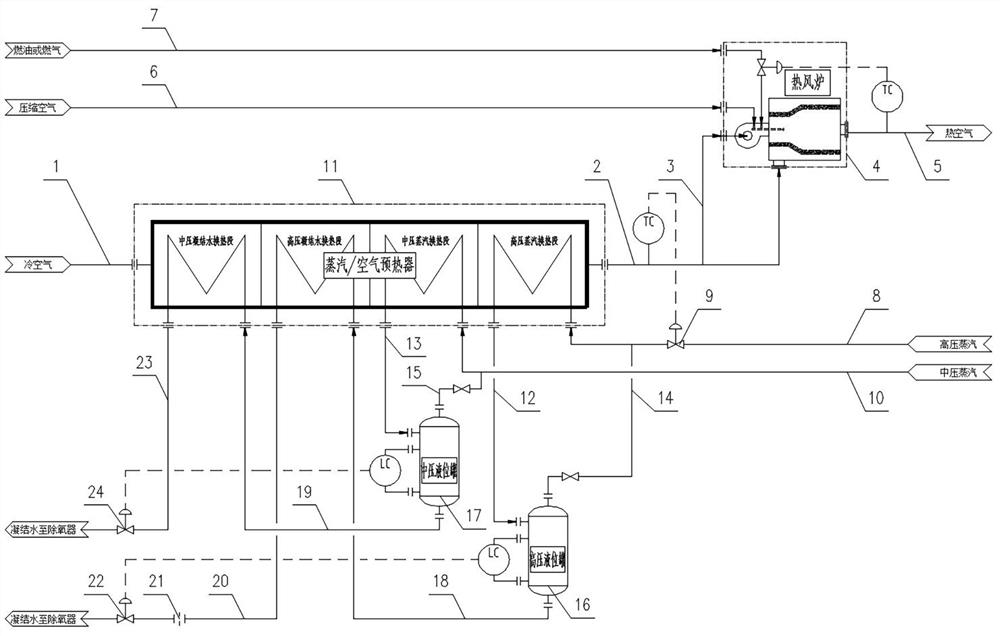

[0054] Such as figure 2 As shown, the structure of this embodiment is roughly the same as that of Embodiment 1, the difference is that:

[0055] The steam / air preheater is a four-stage steam / air preheater 11. In addition to the three stages in the first embodiment, it also includes a medium-pressure condensate heat exchange section. The medium-pressure condensate heat exchange section is connected to the high-pressure condensate The heat exchange section is close to the end of the cold air passage 1, and the outer end of the medium-pressure condensate heat exchange section is the air inlet side, which is connected to the cold air passage 1. The cold air passes through the medium-pressure condensate heat exchange section, the high-pressure condensate heat exchange section, and the medium-pressure steam in sequence. The heat exchange section and the high pressure steam heat exchange section are gradually heated;

[0056] The bottom end of the medium pressure liquid level tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com