Method for cultivating sweet potato seedlings through hotbed

A seedbed and sweet potato technology is applied in the field of cultivating sweet potato seedlings with seedling seedbeds, which can solve the problems of inability to precisely control temperature, inability to control temperature flexibly, slow heating of seed potato layers, etc., so as to avoid failure of seedling breeding, reliable heating, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

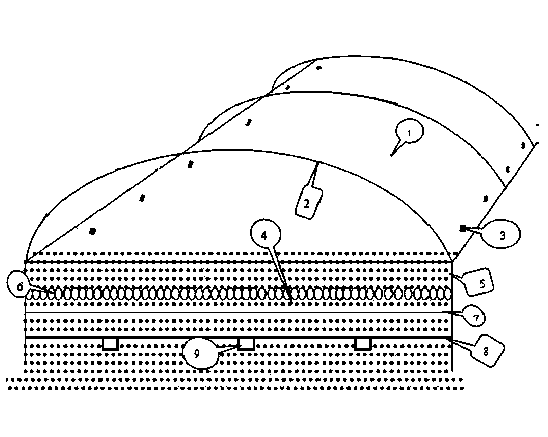

[0028] As shown in the figure, the specific implementation method is as follows:

[0029] A method for cultivating sweet potato seedlings with a seedling breeding hotbed, comprising the following steps:

[0030] 1. Preparation of seedling hotbed and row of potatoes:

[0031] A. Dig a seedbed body with a length of 6m, a width of 2m, and a depth of 0.6m; the length and width of the seedbed can be flexibly adjusted according to the area of the plot and the amount of seedlings raised.

[0032] B. Fill the bottom of the seedbed body with 15-25cm thick soil, and implant the shed skeleton, which is solid and flat;

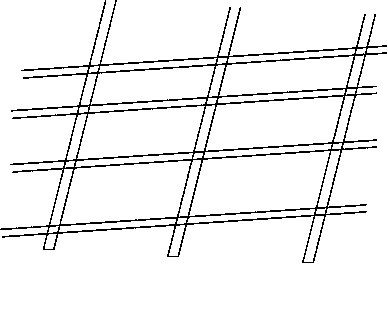

[0033] C. Open grid intercommunicating grooves on the top of the soil after step B has been leveled to form an air guide groove, and then evenly cover straw or branches with a thickness of 4-6cm to form a straw layer;

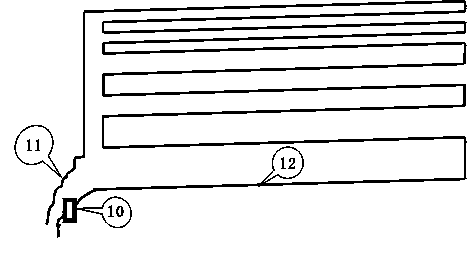

[0034] D. Cover the 8-12cm soil above the straw layer in step C, and lay the heating wire layer after it is solid and level. Each heating wire in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com