Ecological drying system

A drying system and ecological technology, applied in the field of drying, can solve the problems of electric heater drying equipment leakage, high maintenance costs, high drying costs, etc., achieve simple structure, save floor space, and prolong heating time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

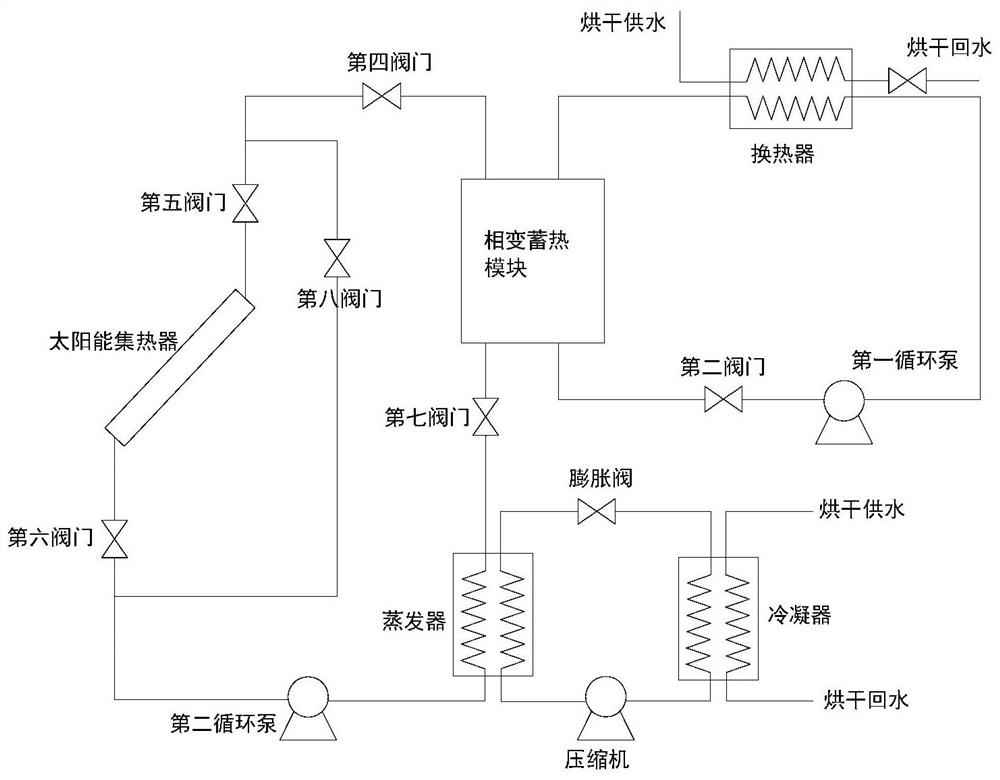

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

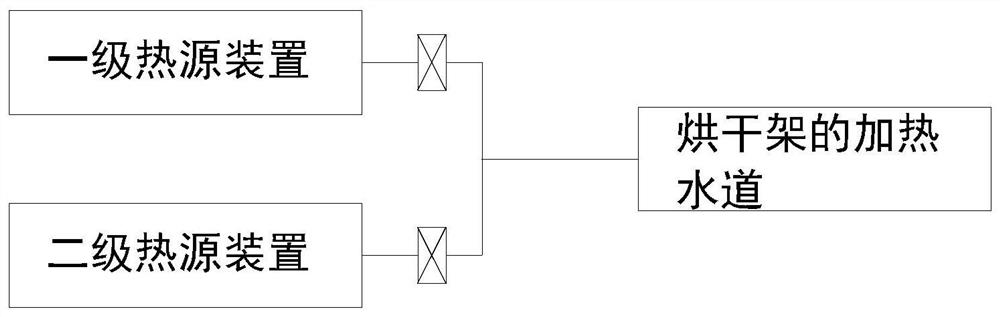

[0036] Such as Figure 1-2 As shown, an embodiment of the present invention discloses an ecological drying system, including a drying rack for drying objects to be dried;

[0037] The drying rack is provided with a main heat source water inlet, a main heat source water outlet, and a first heating channel connecting the main heat source water inlet and the main heat source water outlet;

[0038] The drying rack is connected with a primary heat source device providing a main drying heat source and a secondary heat source device providing an auxiliary heat source;

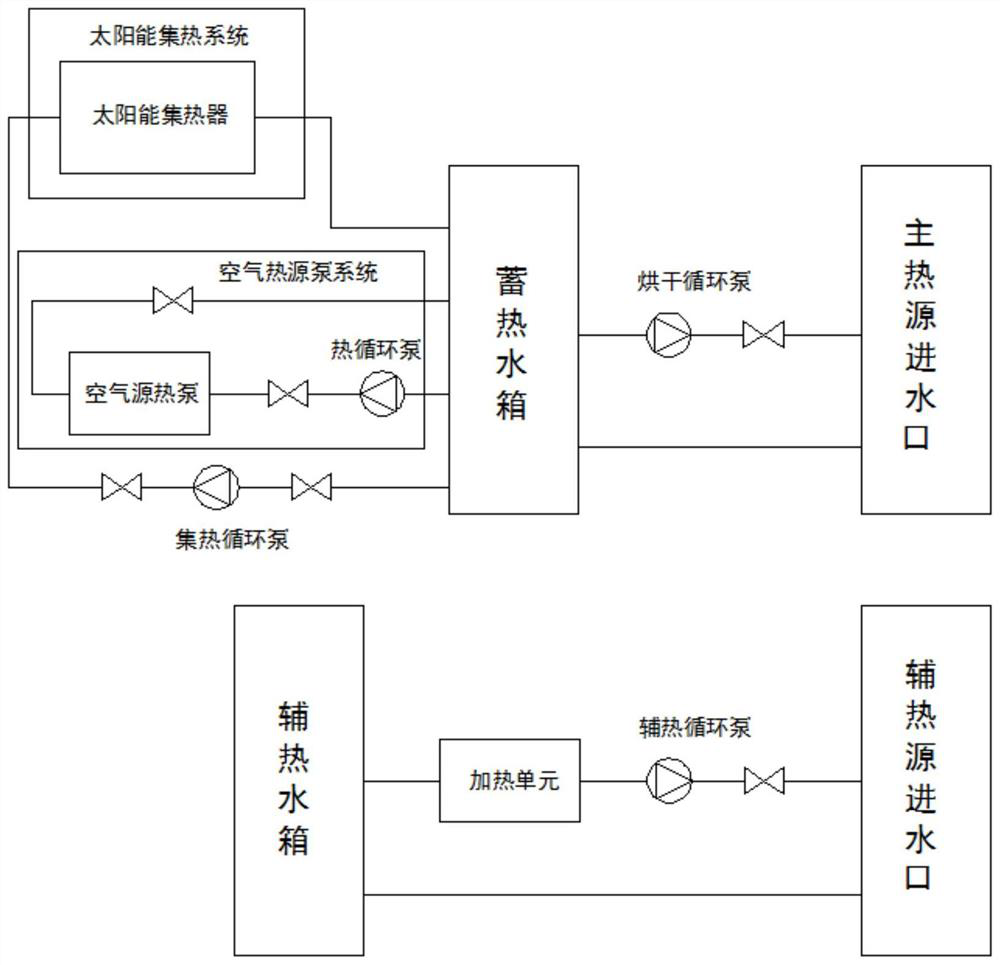

[0039] The primary heat source device includes a solar heat collection system, an air heat source pump system, and a heat storage tank;

[0040] The solar heat collection system includes a solar heat collector, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com