A motor for mineral powder crushing equipment for special mortar preparation

A technology for crushing equipment and motors, which is applied in the direction of electromechanical devices, electrical components, electric components, etc. It can solve the problems of cumbersome disassembly process, moisture in the junction box, and pulling of the wiring parts, so as to save time and effort in the assembly process and ensure the drying effect. , good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

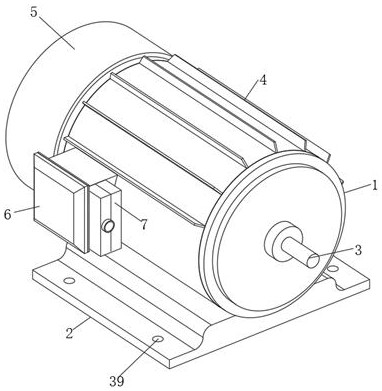

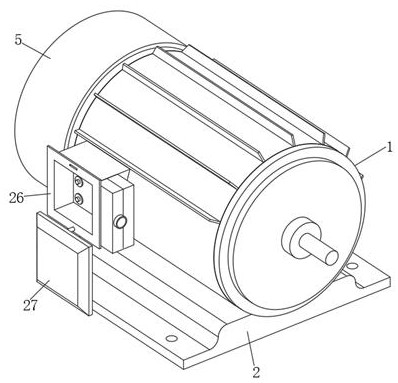

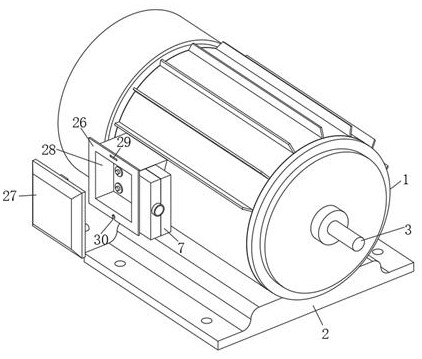

[0038] Such as Figure 1-3 As shown, a motor for mineral powder crushing equipment for special mortar preparation includes a motor housing 1, a rotating shaft 3 is arranged on the front surface of the motor housing 1, and a motor mounting base is fixedly installed on the lower surface of the motor housing 1 2. The rear end of the motor casing 1 is covered with a rear end cover 5, and a junction box 6 is fixedly installed on one side surface of the motor casing 1, and a protective mechanism 7 is provided on one side surface of the junction box 6, so that The inside of the protective mechanism 7 is provided with a wire gathering mechanism 8, the junction box 6 includes a junction box cover 26 and a junction box cover 27, the surface cover of the junction box 26 is provided with a junction box cover 27, and the junction box cover 27 A cover block 31 is fixedly installed on one side surface, an adjustment mechanism 32 is arranged on one side surface of the junction box cover 27 be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com