BUCK-BOOST with high-precision low-ripple light-load working mode

A working mode, low-ripple technology, applied in conversion equipment without intermediate conversion to AC, output power conversion devices, instruments, etc., can solve the problems of slow loop response time, large VOUT voltage ripple, etc., to reduce Voltage ripple, low energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]The present invention will be described in detail below in conjunction with the accompanying drawings.

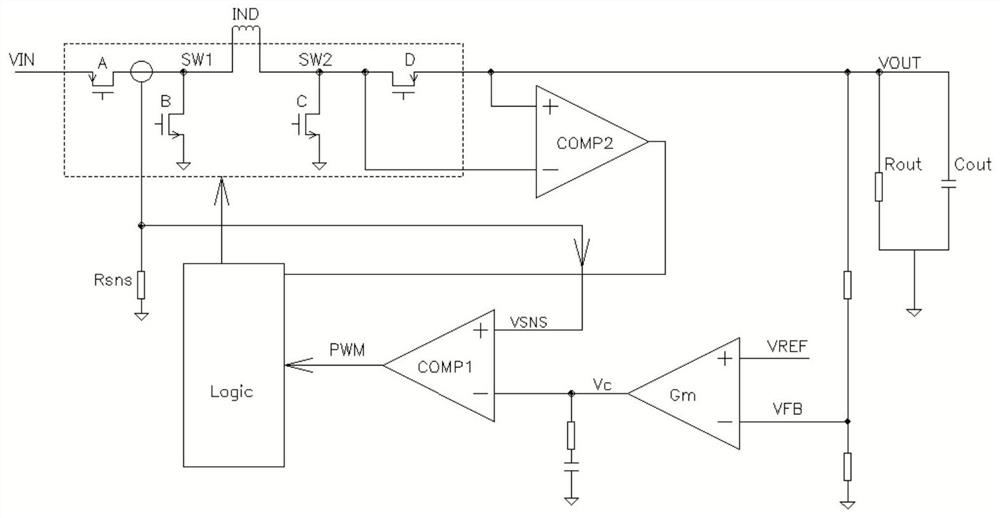

[0026] The system block diagram of the present invention is as Figure 4 shown. The internal reference voltage VREF and VOUT voltage feedback signals are differentially amplified to generate a voltage control signal Vc, and Vc is converted by V / I to generate a current control signal IC and IPFM. There is a clamping circuit on the IC signal path. When the output current of V / I conversion is greater than the value set by the clamping circuit, IC is equal to the output current of V / I conversion. When the output current of V / I conversion is less than the value set by the clamp circuit, IC is equal to the set value. The comparator COMP1 compares the inductor current sampling signal ISNS with IC to generate a pulse width modulation signal PWM. TPFM is a current control delay circuit, the delay time increases with the decrease of IPFM, and a signal pulse T3 is generated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com