Steaming oven with oil refining function and animal fat refining control method

A technology for animal fat and steaming oven, which is applied in the direction of fat oil/fat refining, fat production, kitchen utensils, etc. It can solve the problems of easy generation of a large amount of oil smoke and oil temperature, low quality of liquid oil and low efficiency, etc., so as to avoid the problem of oil deterioration, Guaranteed quality and good experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

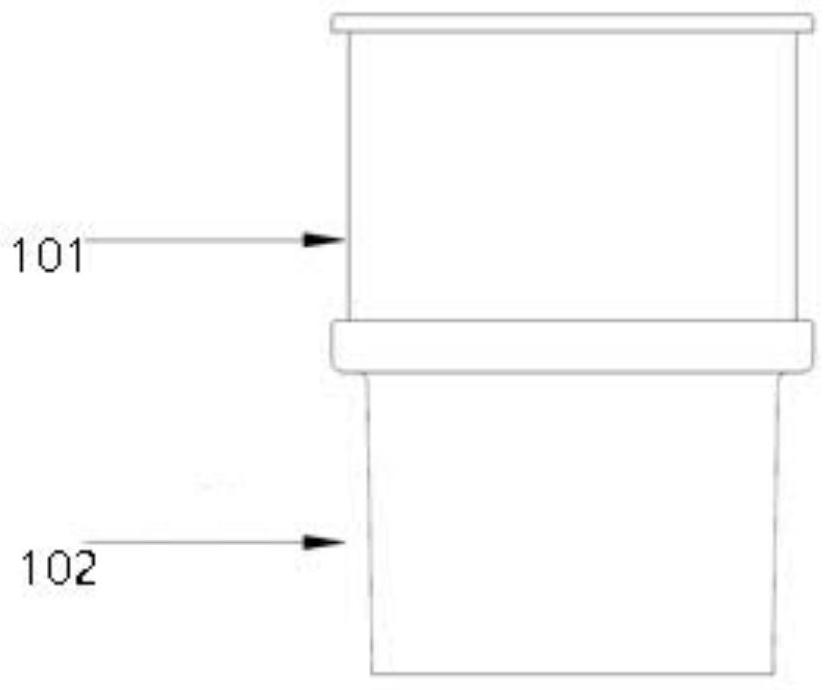

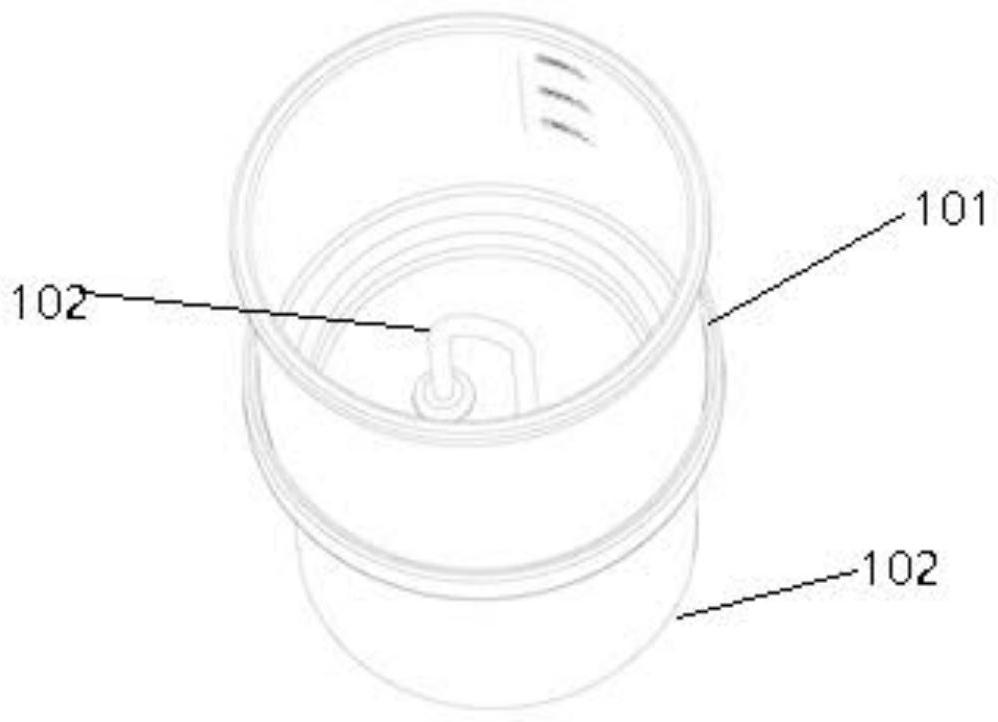

[0043] This embodiment proposes a steam oven with oil refining function, the steam oven includes: an oil refining appliance 100 and an oil refining program for controlling the oil refining process.

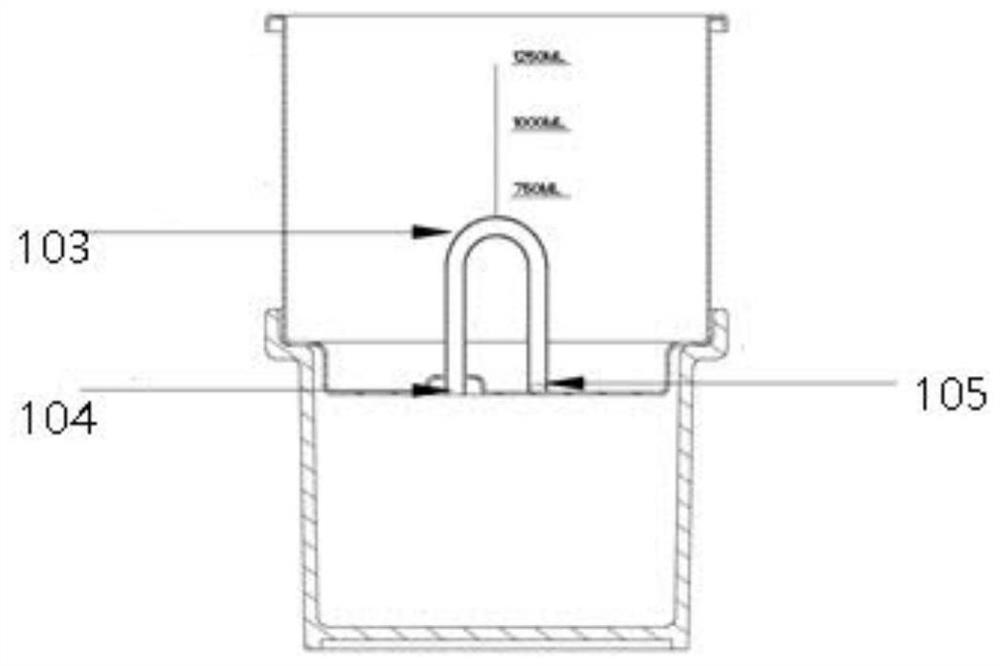

[0044] Such as figure 1 As shown, the oil refining appliance 100 includes an oil refining cup 101 and an oil storage cup 102; as figure 2 As shown, a U-shaped oil discharge pipe 103 is set at the bottom of the refining cup 101; the refining cup 101 and the oil storage cup 102 are separable, and the bottom of the refining cup and the opening of the oil storage cup are matched in structure and size. The oil refining cup can be stuck on the opening of the oil storage cup to form an integrated structure, and the oil refining cup and the oil storage cup can be separated after the oil refining is completed.

[0045] Such as image 3 As shown, the two ends of the U-shaped oil discharge pipe 103 are an oil inlet 105 and an oil outlet 104 . The oil inlet 105 is slightly higher than the...

Embodiment 2

[0071] Such as Figure 5 As shown, this embodiment proposes a method for controlling the refining of animal fats, which is applied to a steam oven with a refining function, including:

[0072] Step 301: Obtain the melting point, smoke point and refining time of the animal fat to be refined;

[0073] Step 302: Turn on the cooking control switch to inject steam into the cavity of the cooking box. After the steam enters the cavity and discharges the original air in the cavity, turn on the baking control switch to increase the temperature of the steam; wherein, after the steam exhausts the original air, The chance of oxidation of high temperature oil in contact with more oxygen is reduced.

[0074] Step 303: By controlling the baking control switch and the steaming control switch, the temperature of the steam in the cavity is maintained between the melting point and the smoke point; specifically:

[0075] Obtain the temperature value of the cavity, and use the PID control algori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com