Material sedimentation hopper with physical defoaming device

A physical defoaming and material technology, which is applied in the sedimentation tank, the feeding/discharging device of the sedimentation tank, sedimentation and separation, etc., can solve the problems of environmental impact, time-consuming and labor-intensive, low efficiency, etc., and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solution and advantages of the technical solution clearer, the technical solution will be further described in detail below in conjunction with specific embodiments. It should be understood that these descriptions are only exemplary, and are not intended to limit the scope of the technical solution.

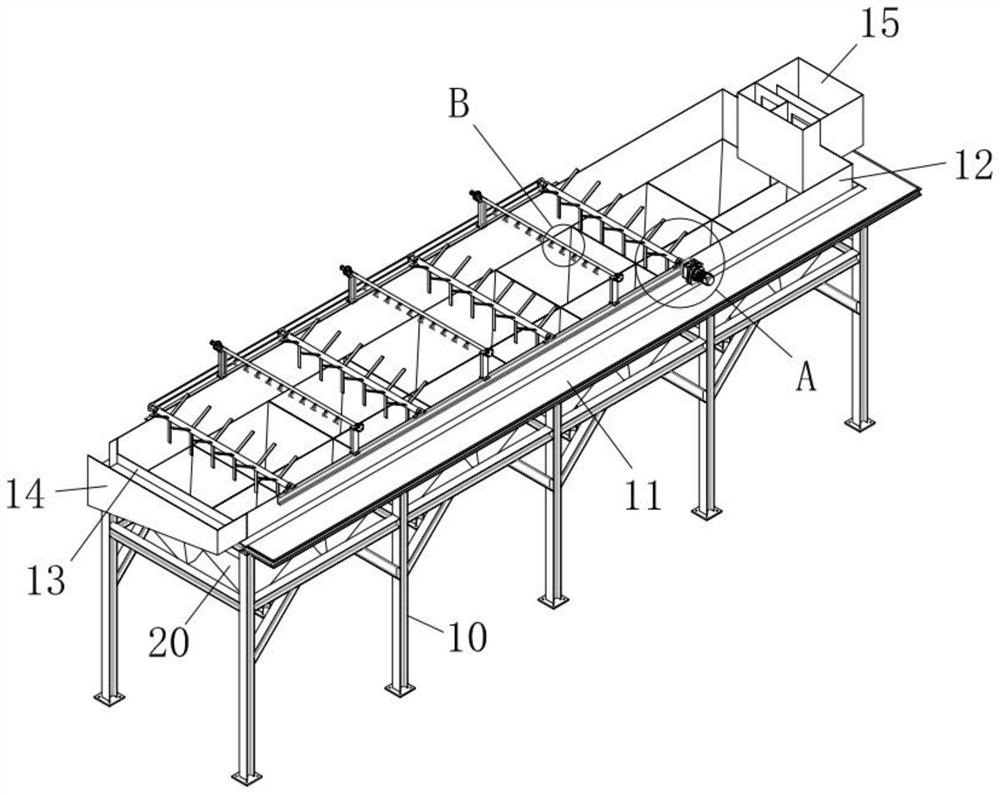

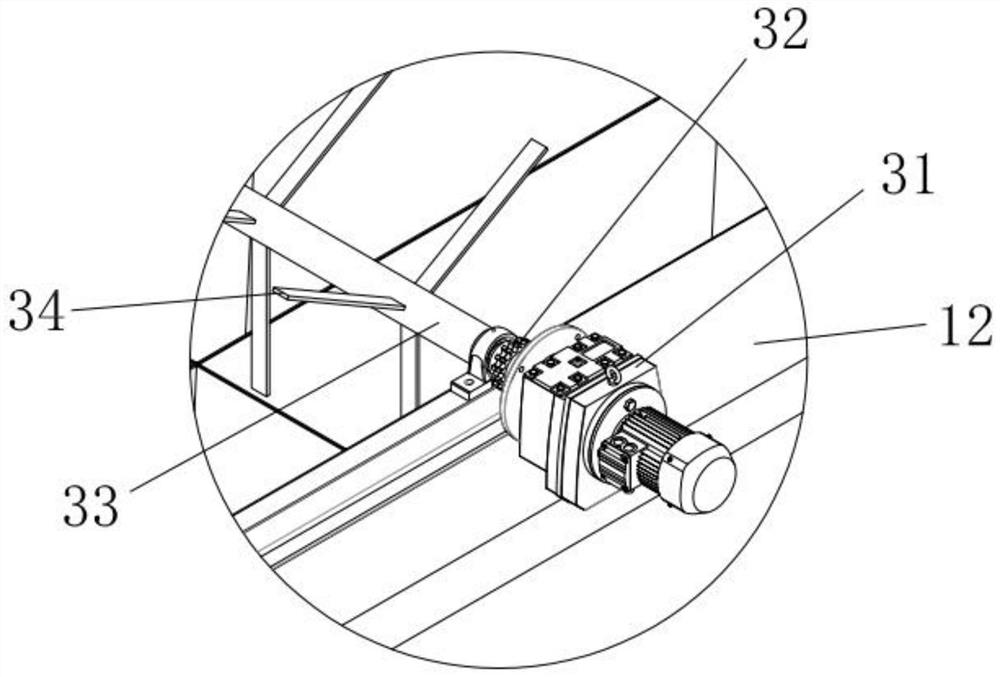

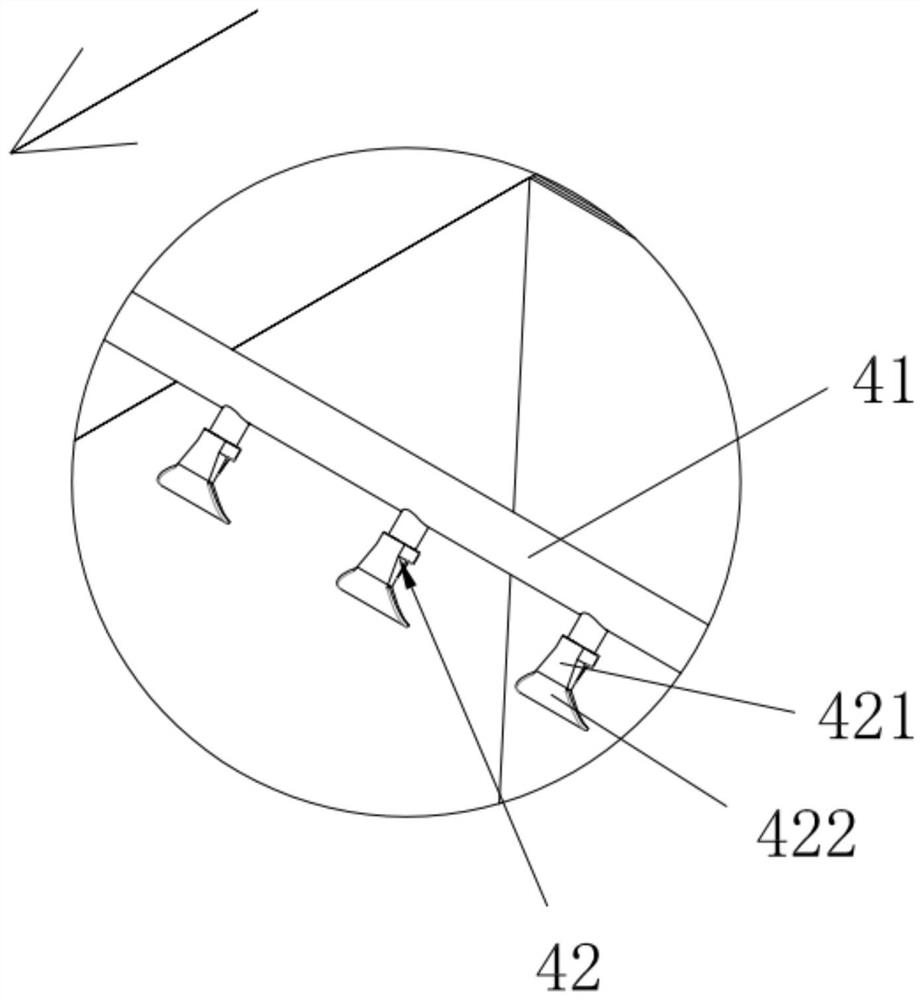

[0029] Such as Figure 1-Figure 7 As shown, this embodiment proposes a material settling hopper with a physical defoaming device, which is used to settle the granular materials in the water body, including a bracket 10, a side wall baffle assembly 12, an overflow baffle 13, a settling type Water inlet device 15, overflow bucket 20, defoaming roller assembly 30 and water spray defoaming assembly 40, wherein the middle part of bracket 10 has a hollowed out position, the hollowed out is rectangular, there are several overflow buckets 20, overflow bucket 20 along the hollowed out Several groups are arranged from the first end to the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com