Steelmaking waste slag slurry treatment system

A steelmaking waste slag and liquid treatment technology, which is applied in grain processing, fixed filter elements, applications, etc., can solve the problem of not forming a steelmaking waste slag slurry treatment system, etc., to increase heat transfer efficiency and reduce waste , the effect of lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

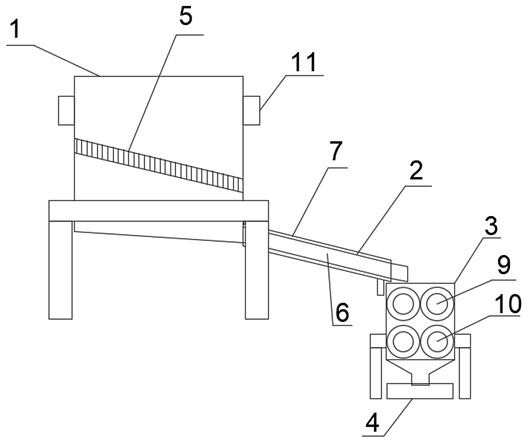

[0028] The steelmaking waste slag slurry treatment system is characterized in that it includes the following treatment steps:

[0029] S1. Filtration: pump the steelmaking waste slag slurry into the filter box 1 for filtration to remove large particles of impurities;

[0030] S2, cooling: collecting the filtrate filtered by S1, and cooling the filtrate through the cooling mechanism 2;

[0031] S3, grinding: adding the cooled filtrate into the grinding box 3 for grinding;

[0032] S4, iron removal: Add the ground filtrate to the iron removal mechanism 4 to remove iron, and then recycle the filtrate after iron removal,

[0033] The invention processes the steelmaking waste slag slurry treatment system through the steps of filtration-cooling-grinding-iron removal, and processes the slurry through a complete set of processes, which can remove the iron in the slag slurry, and the remaining part can be reused, which is relatively easy Waste less.

Embodiment 2

[0035] On the basis of Embodiment 1, the filter box 1 includes a filter box body, an inclined filter screen 5 is arranged in the filter box body, and a liquid outlet pipe is provided at the bottom end of the inclined filter screen 5, which can increase the uniformity of grinding in the subsequent grinding step. Spend.

Embodiment 3

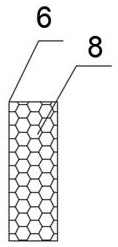

[0037] On the basis of Embodiment 1, the cooling mechanism 2 includes a cooling pipe 6, the liquid inlet end of the cooling pipe 6 is connected to the liquid outlet pipe, and a condensation jacket 7 is sleeved on the outside of the cooling pipe 6, and a water inlet pipe and a water inlet pipe are arranged on the condensation jacket 7. The outlet pipe, the inner wall of the cooling pipe 6 is provided with an inwardly recessed groove 8, the groove 8 is evenly arranged on the inner wall of the cooling pipe 6, and the filtered steelmaking waste slag slurry is cooled and then ground to reduce its temperature , and the heat is transferred to the water in the condensation jacket through heat transfer to reduce the heat loss, increase the heat transfer efficiency and reduce the heat loss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com