Treatment method of high-concentration phosphorus-containing soil

A disposal method and high-concentration technology, applied in the restoration of polluted soil, etc., can solve the problems of endangering the surrounding environment and human health, and achieve the effects of avoiding safety and environmental risks, preventing spontaneous combustion of yellow phosphorus, and isolating the air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

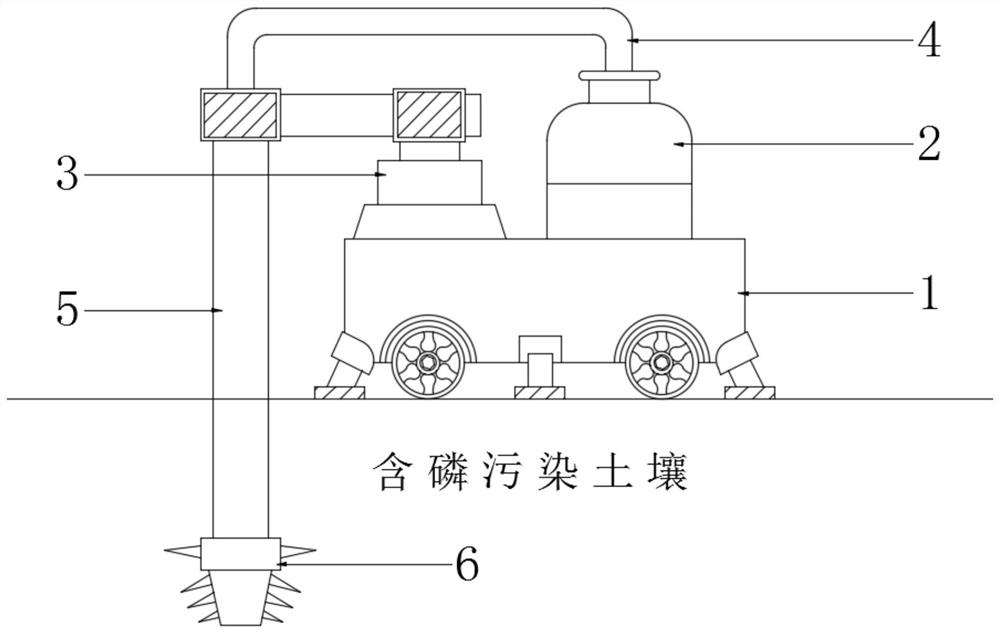

[0034] A method for disposing of high-concentration phosphorus-containing soil, comprising the following steps:

[0035] 1) First, clean up the surface of the phosphorus-contaminated site to ensure that the site of the phosphorus-contaminated site is level;

[0036] 2) Then, according to the distribution of phosphorus pollution in the soil, determine the in-situ injection point. According to the light phosphorus pollution, the injection depth should be kept at about 1-3m, and then the points should be distributed according to a triangle. The interval is 1-3m, because the influence radius of the injection point is 1-3m;

[0037] 3) Afterwards, drive the injection equipment into the phosphorus-contaminated site, inject stabilizing agents into the phosphorus-contaminated soil through the injection pipe under high pressure, and then use the stirring head to stir the soil in situ. The stirring makes the soil structure loose and the porosity increases, so By injecting while stirrin...

Embodiment 2

[0053] A method for disposing of high-concentration phosphorus-containing soil, comprising the following steps:

[0054] 1) First, clean up the surface of the phosphorus-contaminated site to ensure that the site of the phosphorus-contaminated site is level;

[0055] 2) Then, according to the distribution of phosphorus pollution in the soil, determine the in-situ injection point. According to the moderate phosphorus pollution, the depth of injection is kept at 3-4m, and then the points are distributed according to the triangle, and the interval between each point At 1-3m, because the influence radius of the injection point is 1-3m;

[0056] 3) Afterwards, drive the injection equipment into the phosphorus-contaminated site, inject stabilizing agents into the phosphorus-contaminated soil through the injection pipe under high pressure, and then use the stirring head to stir the soil in situ. The stirring makes the soil structure loose and the porosity increases, so By injecting w...

Embodiment 3

[0067] A method for disposing of high-concentration phosphorus-containing soil, comprising the following steps:

[0068] 1) First, clean up the surface of the phosphorus-contaminated site to ensure that the site of the phosphorus-contaminated site is level;

[0069] 2) Then, according to the distribution of phosphorus pollution in the soil, determine the in-situ injection point. According to the high level of phosphorus pollution, the injection depth is kept at about 6m, and then the points are distributed according to a triangle, and the interval between each point is 1 -3m, because the influence radius of the injection point is 1-3m;

[0070] 3) Afterwards, drive the injection equipment into the phosphorus-contaminated site, inject stabilizing agents into the phosphorus-contaminated soil through the injection pipe under high pressure, and then use the stirring head to stir the soil in situ. The stirring makes the soil structure loose and the porosity increases, so By inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com