CNC machining center capable of improving product quality

A machining center and product quality technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of low production efficiency, single style, and few types, so as to achieve output improvement, quality improvement, and avoid deviation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

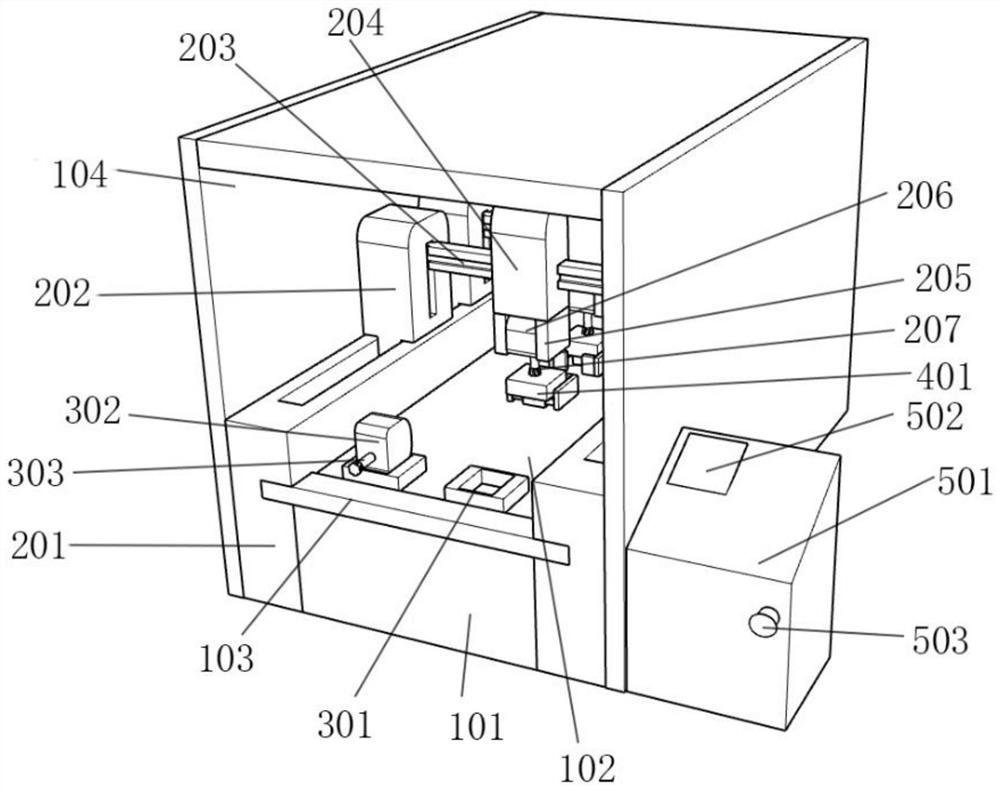

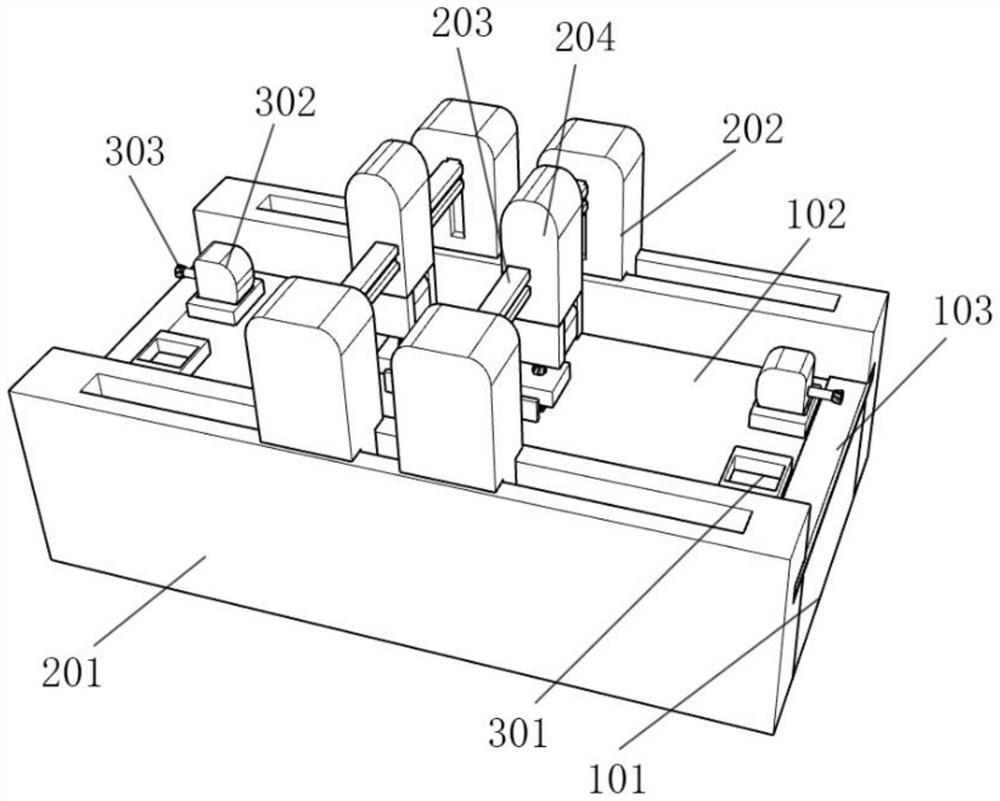

[0027] The present invention provides a kind of CNC processing center that improves product quality, with reference to figure 1 , including a main body mechanism 1, a cutting and grinding mechanism 2, and a control mechanism 5, and also has: the main body mechanism 1 includes a bottom box 101, a bottom plate 102, an edge fixing plate 103, and a casing 104;

[0028] Cutting and grinding mechanism 2: installed at both ends of the main body 1, and fixedly connected with the main body 1;

[0029] Backup mechanism 3: installed on the top of the main mechanism 1, and fixedly connected with the main mechanism 1;

[0030] Fixing mechanism 4: installed on the top of the main body 1, and fixedly connected with the main body 1;

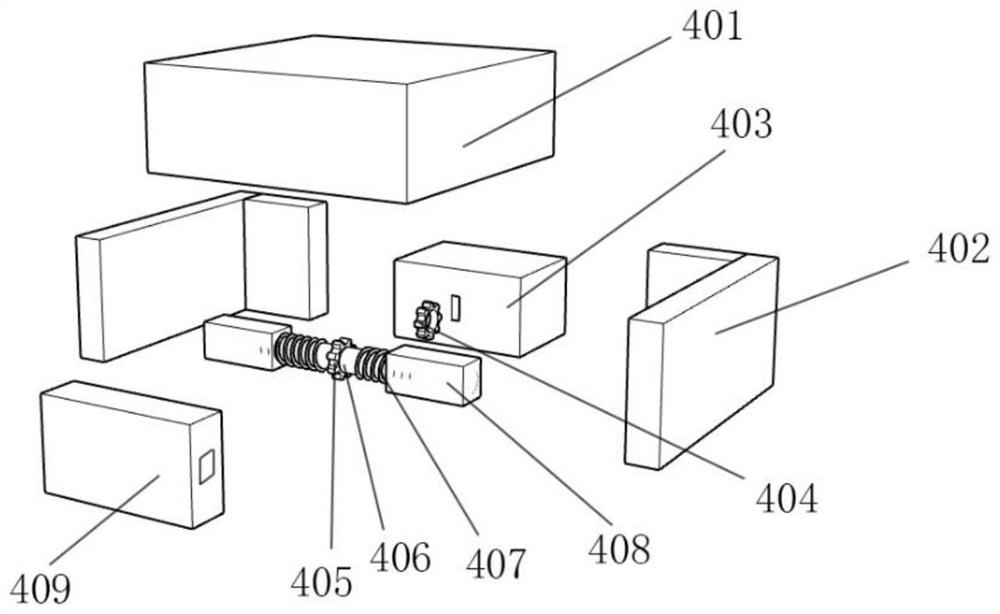

[0031] refer to image 3 Further, the fixing mechanism 4 includes an object to be processed 401, a fixed clamp column 402, a gear box 403, an output gear 404, an auxiliary gear 405, a double-ended column 406, a double-ended thread 407, a fixed double-ended cyl...

Embodiment 2

[0037] refer to Figure 4 Further, the object 401 to be processed is movably connected to the top of the second mechanism 7, the second mechanism 7 includes the second base 701, the second mounting seat 702, the second mounting plate 703, the pneumatic telescopic cylinder 704, the pneumatic telescopic column 705, The gas injection port 706, the object 401 to be processed is movably connected to the top of the second base 701, the top of the bottom plate 102 is fixedly connected with two bases 701 of the second example, and the top of the bottom plate 102 is fixedly connected with four mounting bases 702 of the second example and are located in the second example On both sides of the base 701, the top side of the mounting seat 702 of Example 2 is fixedly connected with the mounting plate 703 of Example 2, and the inner side of the mounting plate 703 of Example 2 is fixedly connected with a pneumatic telescopic tube 704, and the inner side of the pneumatic telescopic tube 704 is ...

Embodiment 3

[0039] refer to Figure 5 , the object to be processed 401 is movably connected to the top of the example 3 mechanism 6, the example 3 mechanism 6 includes the example 3 base 601, the example 3 mounting seat 602, the motor mounting plate 603, the example 3 motor 604, the example 3 output shaft 605, the example 3 thread 606, example three push column 607, the object 401 to be processed is movably connected to the top of the example three base 601, the top of the bottom plate 102 is fixedly connected with two example three bases 601, and the top of the bottom plate 102 is fixedly connected with four example three mounting seats 602 And it is located on both sides of the base 601 of the third example, the top side of the mounting seat 602 of the third example is fixedly connected with the motor mounting plate 603, the side of the motor mounting plate 603 is fixedly connected with the motor 604 of the third example, and the inner top of the motor 604 of the third example is movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com