Sand blasting robot

A robot and robot body technology, applied in abrasive jet machine tools, spray guns, used abrasive processing devices, etc., can solve problems such as low efficiency, single robot, and difficulty in adapting to high-altitude operations, and achieve high work efficiency and scientific structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] One of the embodiments of the present invention, a model with two spray guns, will be described below in conjunction with the accompanying drawings. It should be understood that the embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

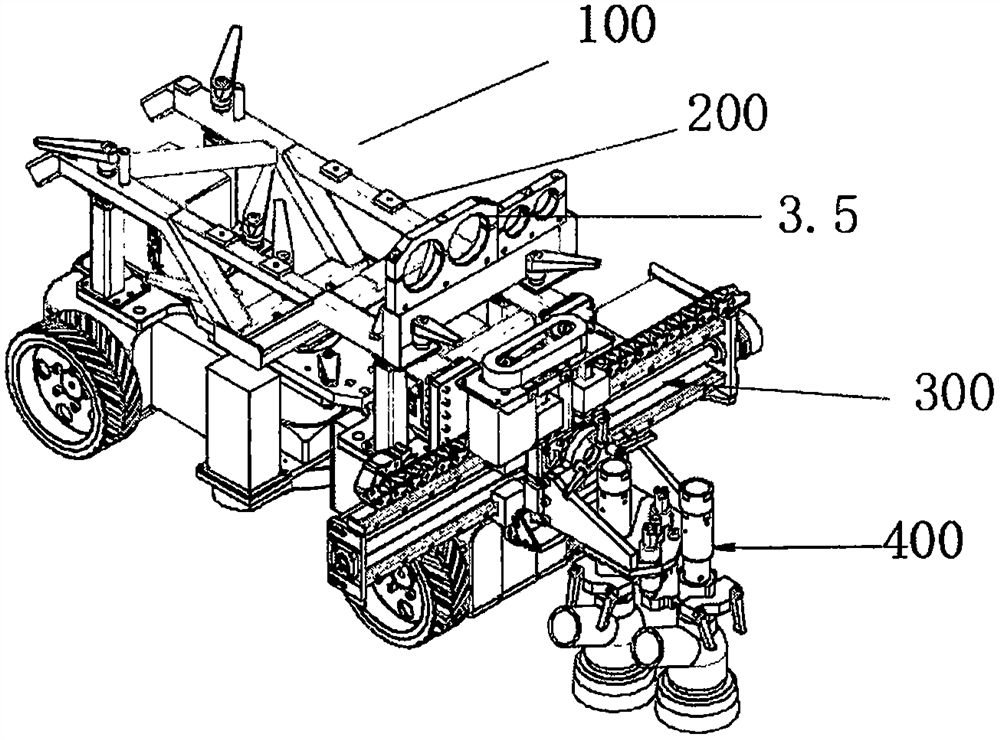

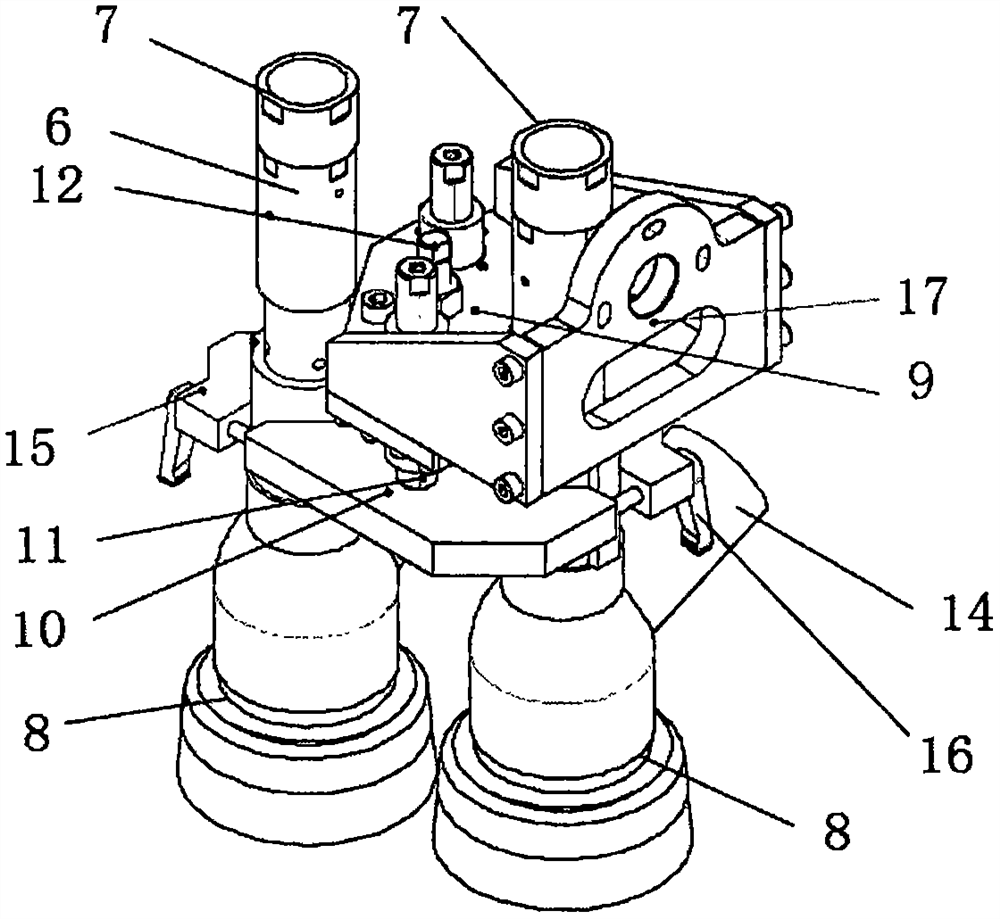

[0027] like Figure 1 to Figure 4 As shown, a sandblasting robot 100 includes: a robot body 200, a connecting transition assembly 300, and a sandblasting device 400; at one end of the robot body, connecting the transition assembly and the sandblasting device;

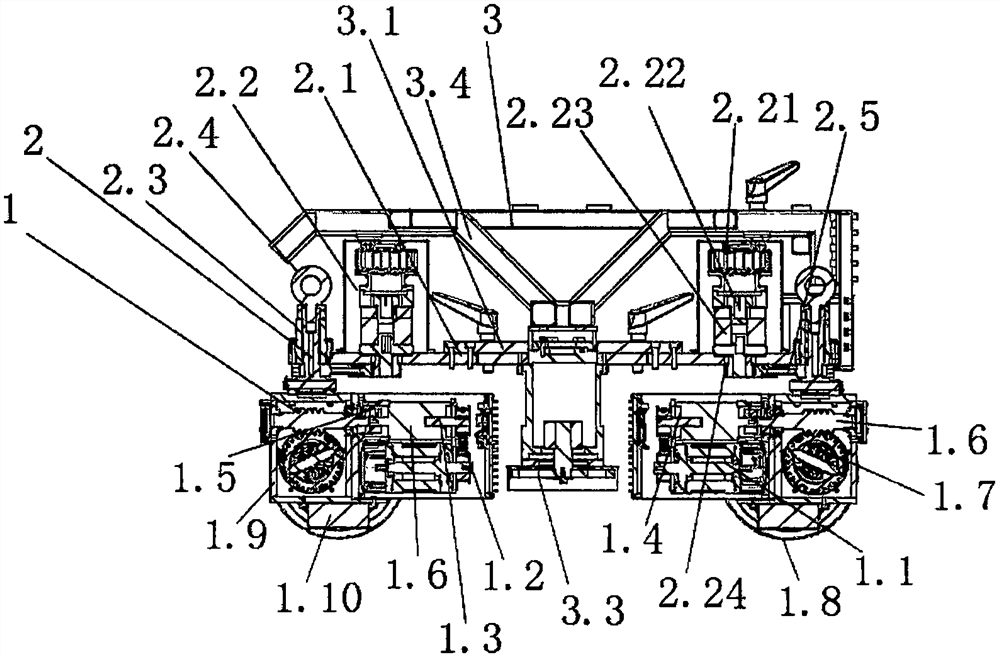

[0028] The robot body 100 includes a running mechanism 1, a steering mechanism 2, and a turning mechanism 3; the walking mechanism has two identical sets, and the turning mechanism is located in the middle of the two walking mechanisms, and the steering mechanism is located in the walking mechanism. above;

[0029] Described traveling mechanism 1, it is to connect synchronous belt, wheel 1.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com