Direct-acting swing hydraulic actuator for articulated robot

A hydraulic actuation and robot technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as large starting friction, difficult sealing, large size, etc., to reduce starting friction, reduce friction, improve servo performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

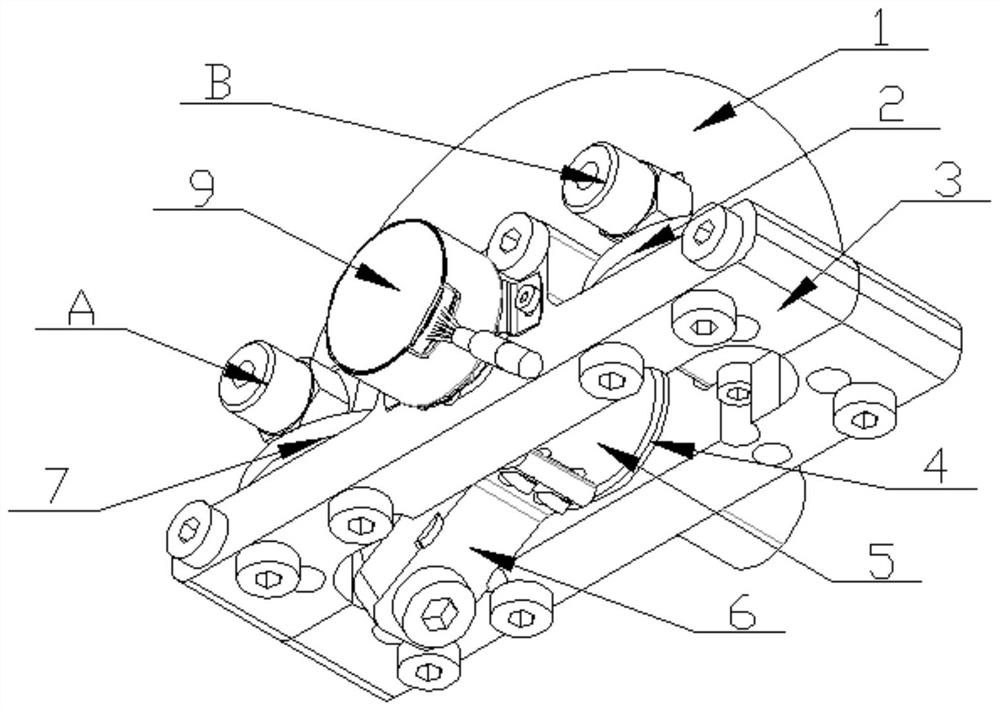

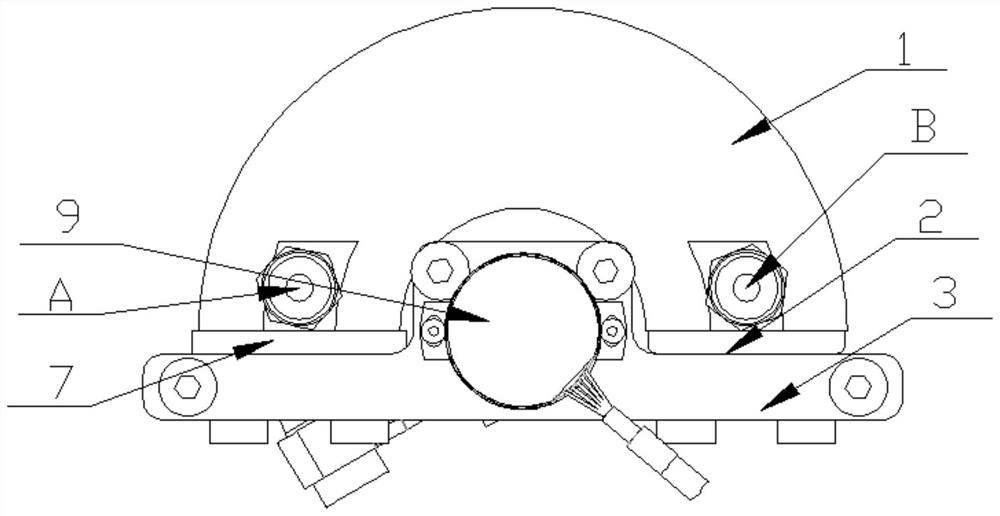

[0022] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, a direct-acting swing hydraulic actuator for an articulated robot in this embodiment, which includes an arc-shaped cylinder body 1, a rear end cover 2, a base 3, a flanged bushing 4, a swing shaft 5, Swing connecting rod 6, front end cover 7, encoder 9, arc blade 15 and arc blade connecting rod 16;

[0023] The base 3 is convex and the middle part of the base 3 is provided with a through groove, the inside of the arc-shaped cylinder 1 is an arc-shaped cavity, and the through-groove and the arc-shaped cylinder 1 are arranged corresponding to each other;

[0024] The lower end surface of the front end cover 7 and the lower end surface of the rear end cover 2 are sequentially arranged on the two ends of the same side of the upper end surface of the base 3 along the length direction of the base 3 from left to right, and the arc-shaped cylinder 1 passes through the length direction of t...

specific Embodiment approach 2

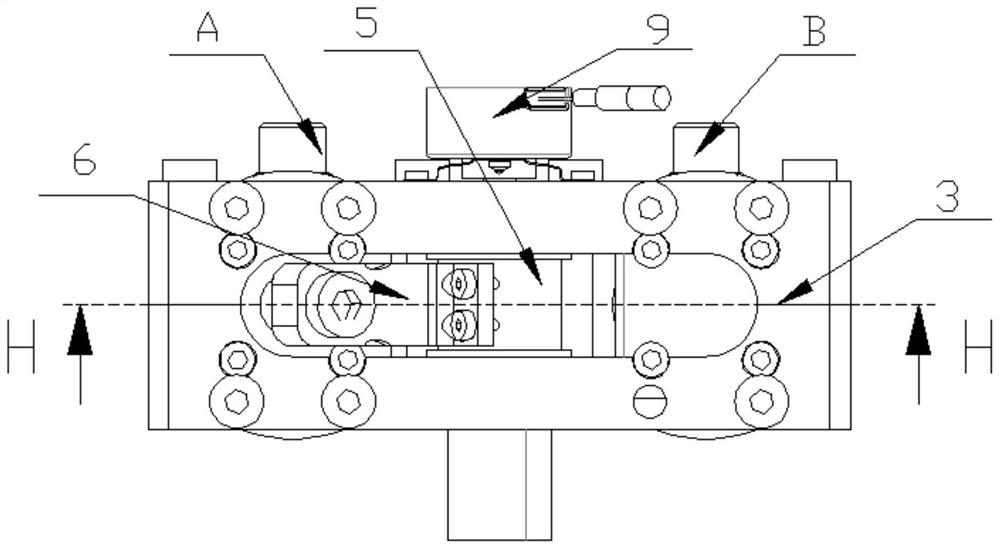

[0027] Specific implementation mode two: combination Figure 4 Describe this embodiment, it also includes the first guide ring 12 of the blade and the second guide ring 14 of the blade in this embodiment;

[0028] The both sides of the outer circumferential surface of arc-shaped blade 15 are respectively sleeved with blade first road guide ring 12 and blade second road guide ring 14, and the outer side wall of blade first road guide ring 12 and the blade second road guide ring 14 The outer sidewalls are slidingly arranged relative to the inner sidewall of the arc-shaped cavity, and the first guide ring 12 of the blade is located on one side of the rear end cover 2 .

[0029] The arrangement of the first guide ring 12 and the second guide ring 14 of the vanes can ensure that the arc vanes 15 do not directly contact and rub against the inner wall of the arc cylinder 1, thereby improving their life and reducing friction. Others are the same as the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination Figure 4 To illustrate this embodiment, it also includes a blade sealing ring 13 in this embodiment,

[0031] The outer peripheral surface of the arc-shaped blade 15 is covered with a blade sealing ring 13 , and the blade sealing ring 13 is located between the first blade guide ring 12 and the second blade guide ring 14 .

[0032] Such setting is to reduce frictional force while ensuring sealing.

[0033] Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com