Cold area steel plate automatic feeding method based on machine vision

An automatic feeding and machine vision technology, which is applied to conveyors, conveyor objects, conveyor control devices, etc., can solve the problem of inability to accurately control the start and stop of the roller table, to fully realize automatic feeding, and optical detection signal interference. and other problems, to achieve the effect of reducing labor costs, equipment maintenance costs, and hardware equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0030] The invention provides an automatic feeding method for steel plates in a cold zone based on machine vision.

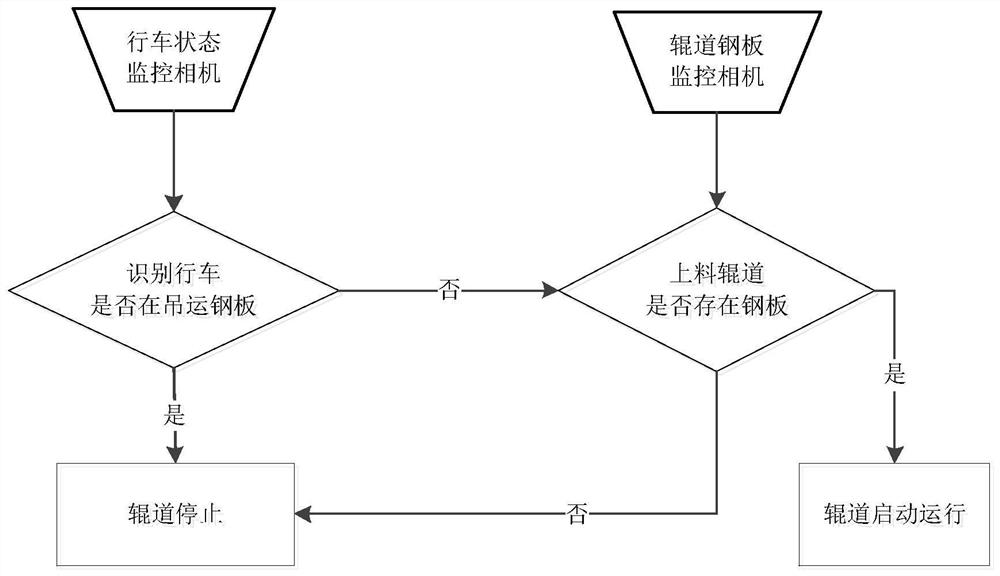

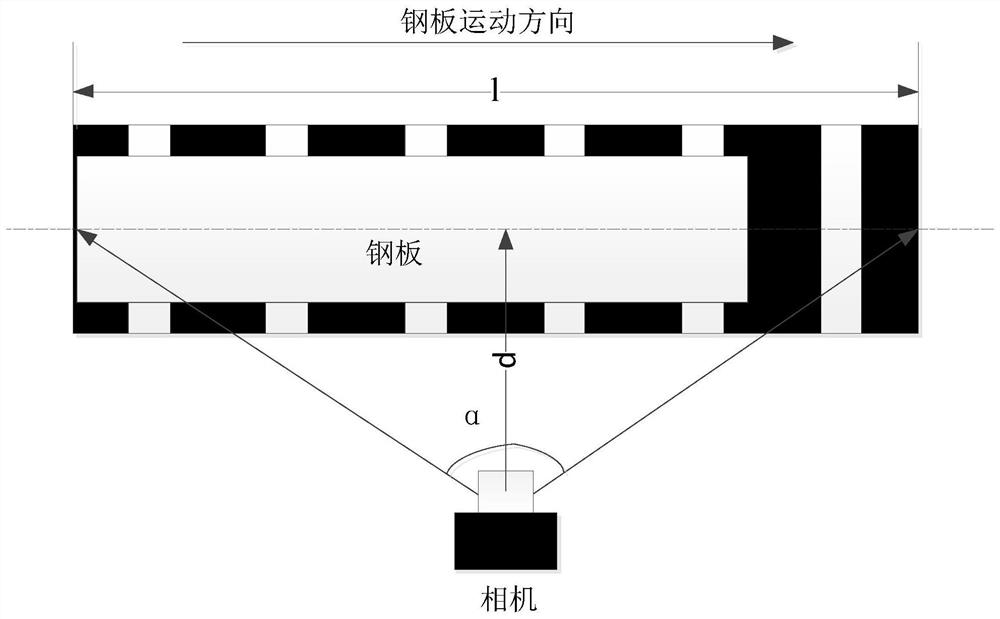

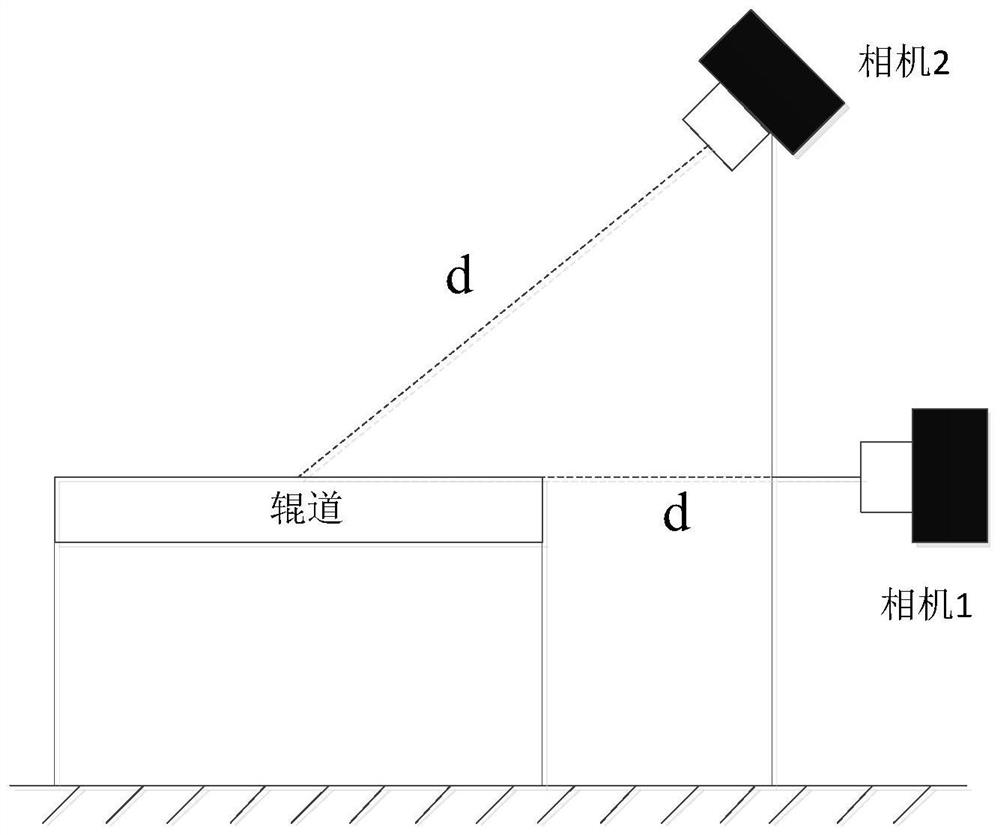

[0031] Such as figure 1 As shown, in this method, monitoring cameras are installed equidistantly on the operating side of the steel plate feeding roller table in the cold zone. The cameras are used to photograph the state of the steel plate on the roller table and the state of the driving position, and use image processing technology to determine whether there is a steel plate on the roller table and calculate the travel time. The distance between the car and the surface of the roller table, and then the start and stop of the roller table are determined by the different combinations of the steel plate state of the roller table and the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com