Winding drum speed reduction all-in-one machine

An all-in-one machine and reel technology, applied in the direction of the hoisting device, the spring mechanism, etc., can solve the problems of unfavorable space arrangement, large space occupied by the reel structure, etc., to reduce the volume, improve the structure compactness, and increase the load. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

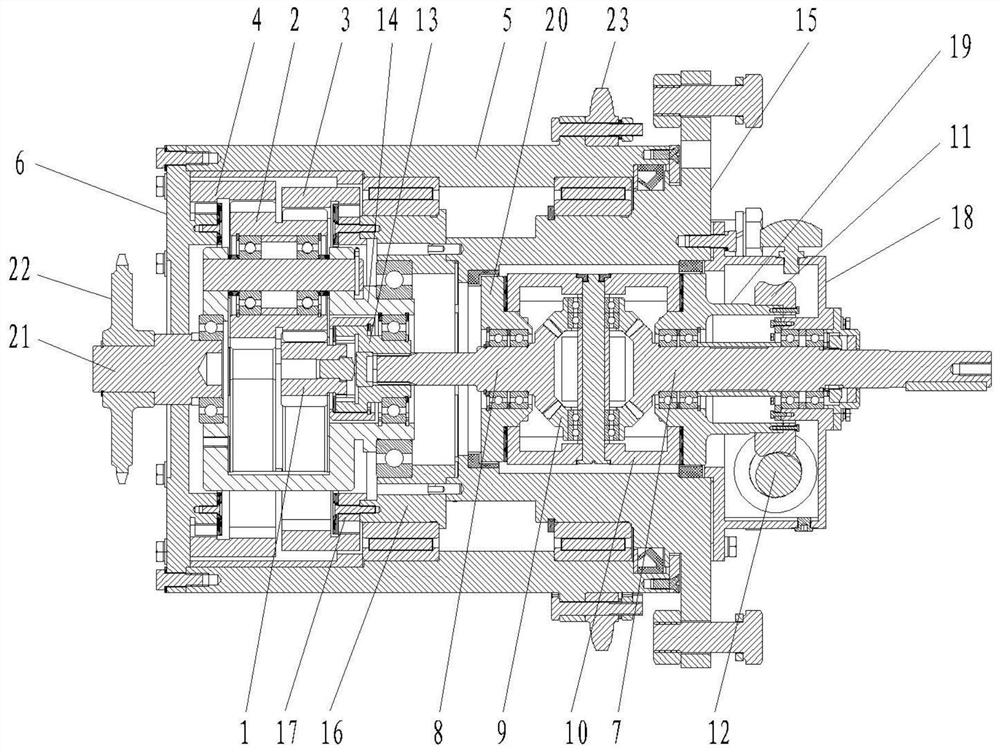

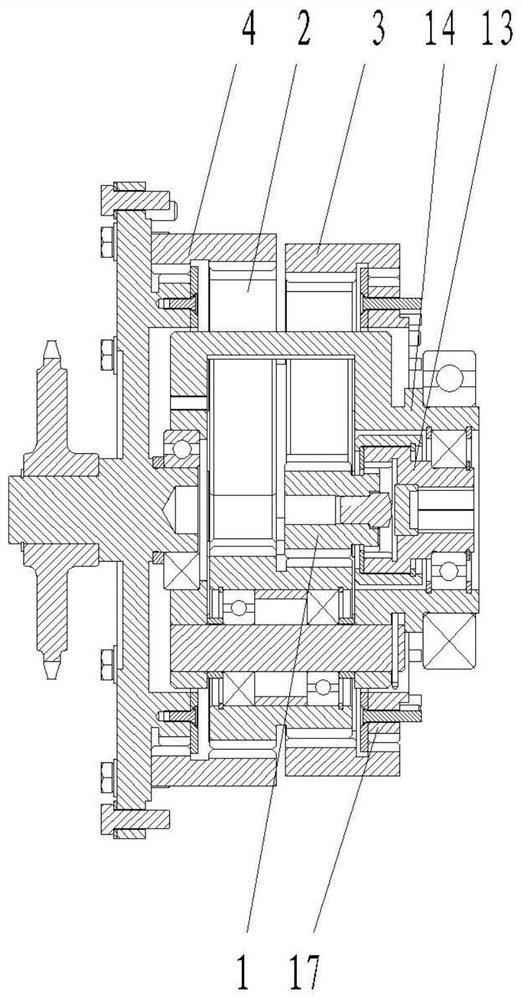

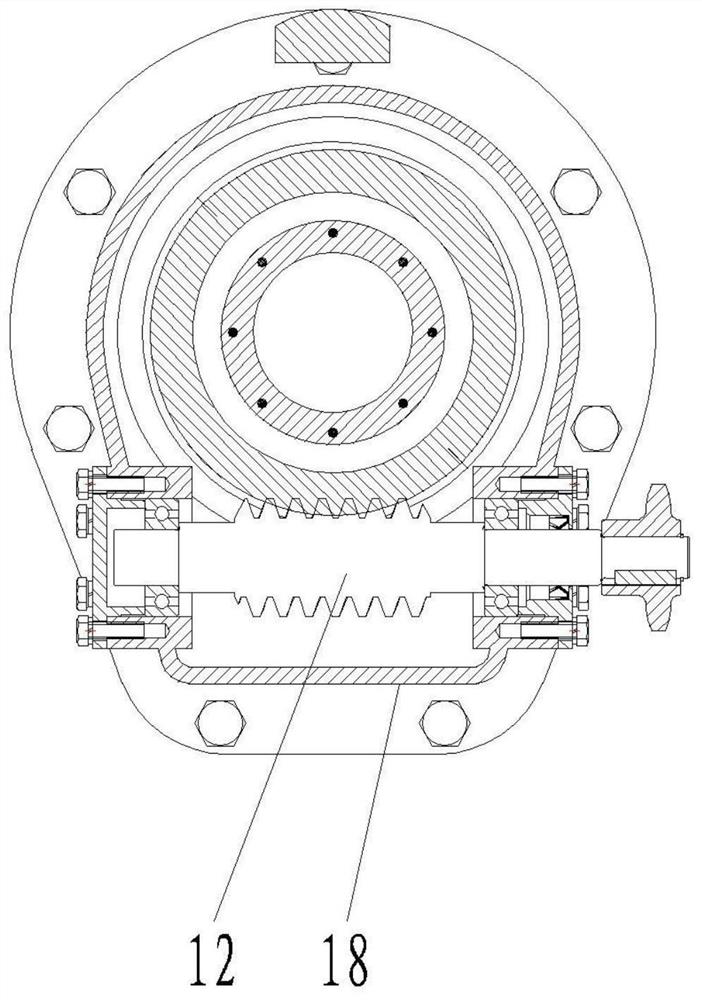

[0022] As shown in the figure: the reel speed reducer of this embodiment includes a sun gear 1, a double planetary gear 2, a ring gear 3, a ring gear 4, an outer cylinder 5 and a gear cover 6. The sun gear 1. The double planetary gear 2, the first ring gear 4 and the second ring gear 5 constitute a planetary gear train, and the double planetary gears mesh with the first ring gear and the second ring gear respectively, and the first ring gear 3 As a fixed end, the planetary gear train is installed in the outer cylinder, the gear cover is fixed on the left end of the outer cylinder, and the second ring gear is used as an output end to drive and cooperate with the gear cover. combine figure 1 As shown, the double planetary gear is a double planetary gear and is used as a planetary gear in the planetary gear train. There are multiple double planetary gears around the sun gear, and the sun gear meshes with the pinion of the double planetary gear. The double planetary gear The pini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com