Stirling refrigerator and assembly method

A technology for refrigerators and regenerators, which is applied to household refrigeration devices, refrigerators, refrigeration components, etc., can solve the problems of excessive mass and volume of the ejector and large dead volume of the compression chamber, so as to reduce the processing difficulty and cost, improve the Compact structure, the effect of reducing dead volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

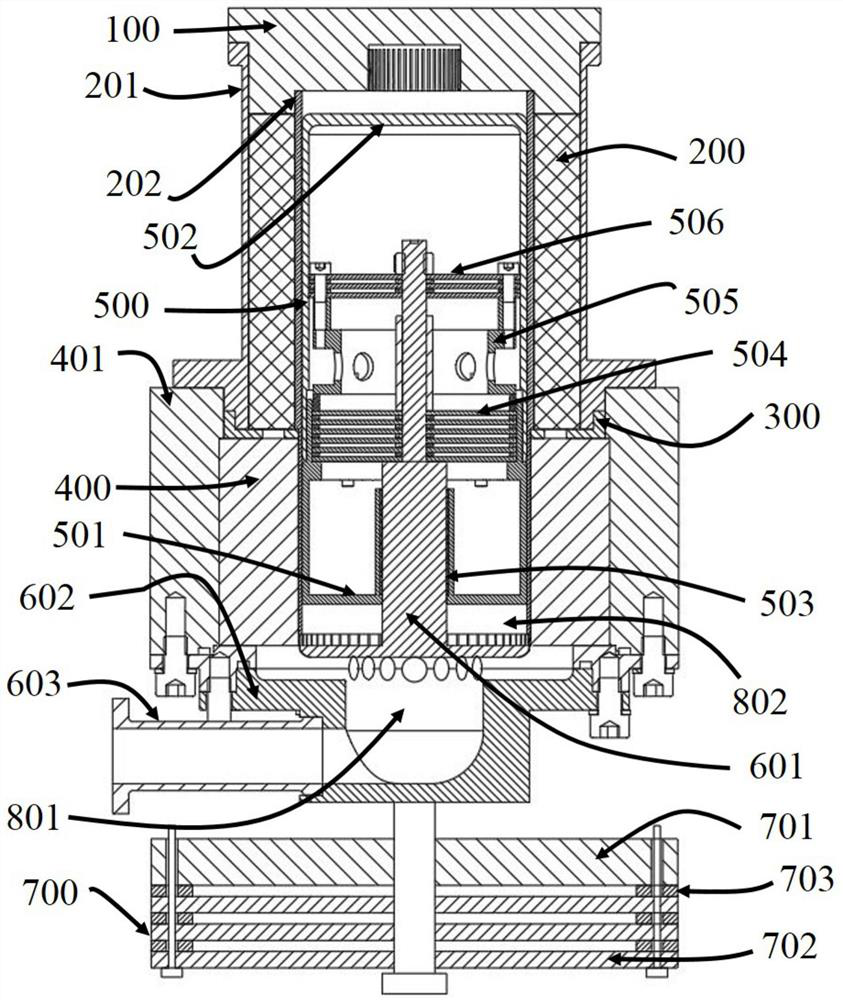

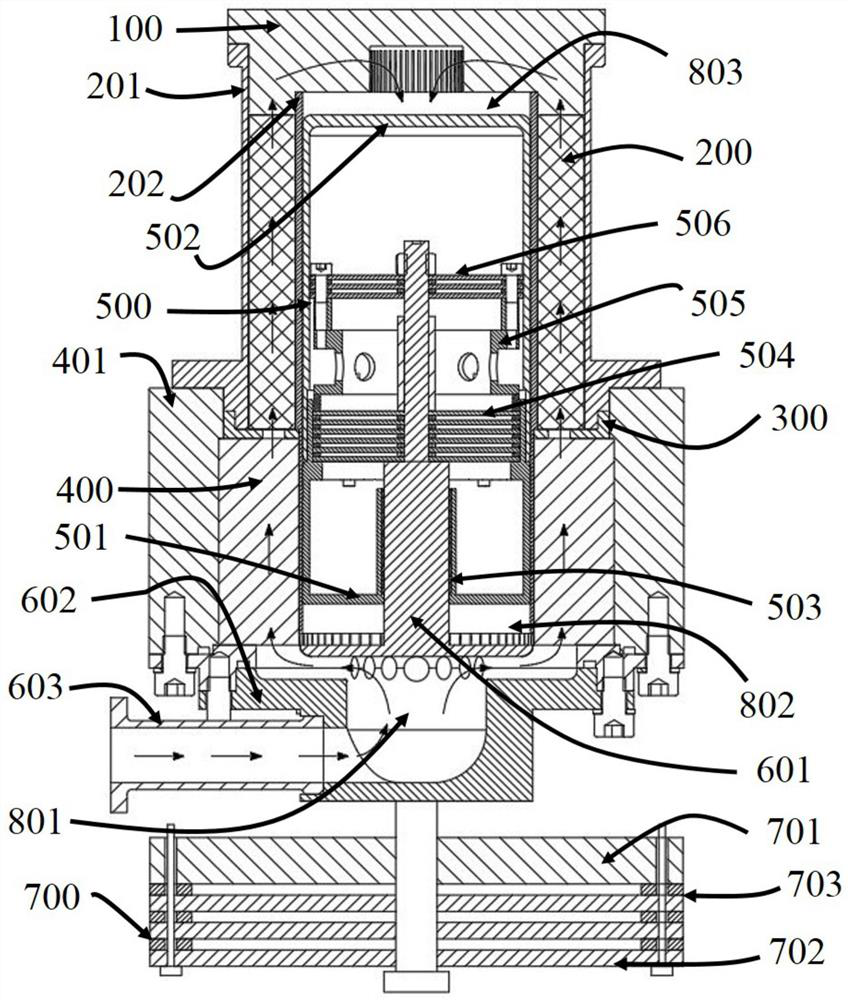

[0049] A specific assembly implementation method of the described Stirling refrigerator device has the following steps:

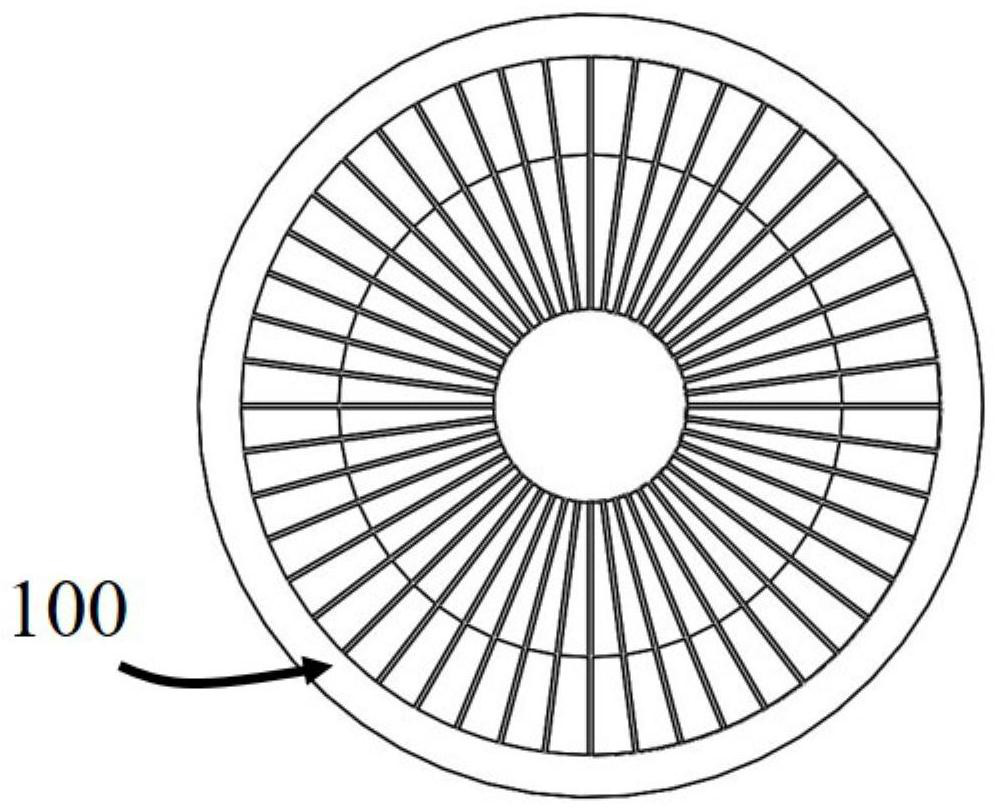

[0050] I. With the aid of positioning tooling, match the regenerator shell 201 with the cold-end heat exchanger 100, and perform vacuum brazing and sealing at the outer connection. After checking the airtightness of the weld, insert the regenerator inner wall 202 into the cold end. In the end heat exchanger 100, at the same time, the external positioning tool is used to ensure that the coaxiality between the inner wall 202 of the regenerator and the shell 201 of the regenerator is not greater than 0.03mm, and then the inner wall 202 of the regenerator is connected to the cold end heat exchanger 100 by a small amount of low-temperature epoxy glue. fixed;

[0051] II. Fill the cold accumulator 200 with stainless steel wire mesh with a wire diameter of 0.23um. The actual porosity after filling is about 0.785. After the filling is completed, install the diversi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slit width | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com