Special filler applied to metal smelting

A metal smelting and metal mining technology, applied in the direction of fluidized bed furnace, etc., can solve the problems of unfavorable development, low reserves, high coke price, etc., and achieve the effect of reducing the generation of powder, increasing the reaction intensity and stabilizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

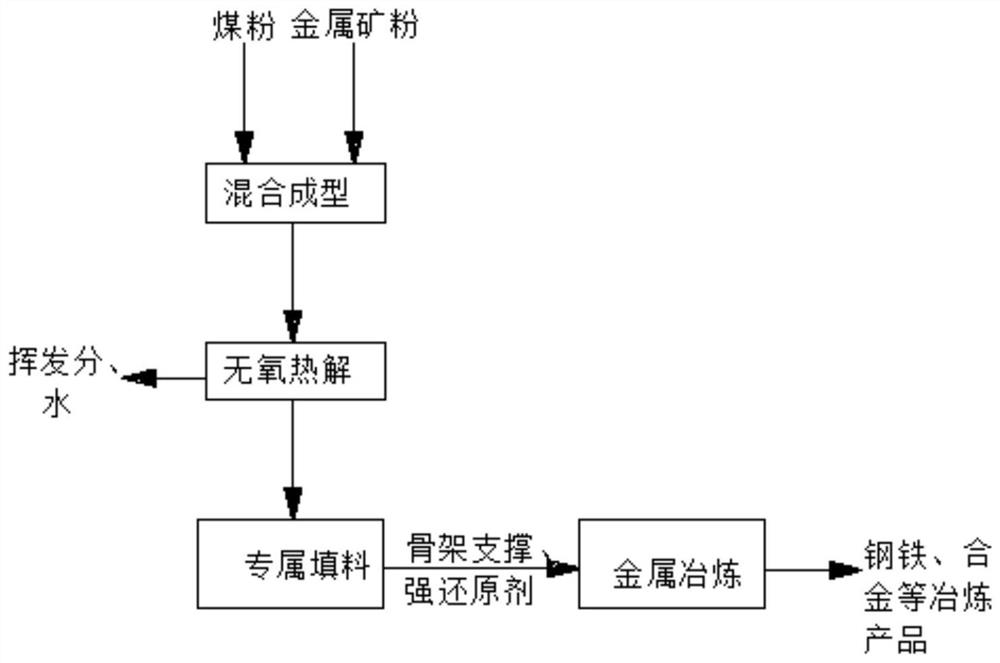

[0014] The present invention will be further described below in conjunction with accompanying drawing.

[0015] Such as figure 1 As shown, a kind of exclusive filler for metal smelting is characterized in that: the exclusive filler is mixed and shaped by coal powder and metal ore powder, and is obtained by anaerobic pyrolysis to remove moisture and volatile matter. It is made of carbon fixation, The molding material composed of ash and metal ore powder.

[0016] The porosity of the exclusive filler is ≥45%, and has good reactivity.

[0017] The exclusive filler has a stable structure, good compression resistance, and can withstand a weight of more than 100kg.

[0018] The shape of the exclusive filler can be adjusted according to the needs of back-end customers.

[0019] Working principle: The metal ore powder is mixed and formed with coal powder in proportion, and the formed mixture is subjected to anaerobic pyrolysis to remove the moisture and volatile matter in the coal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com