Transverse pull type three-stage flap valve and operation method thereof

A horizontal pull type and horizontal tie rod technology, applied in the horizontal pull type three-stage flap door and its operation field, can solve the problems of large water head loss, large pump body, imperfect technology, etc., and achieve reduced friction, simple structure, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

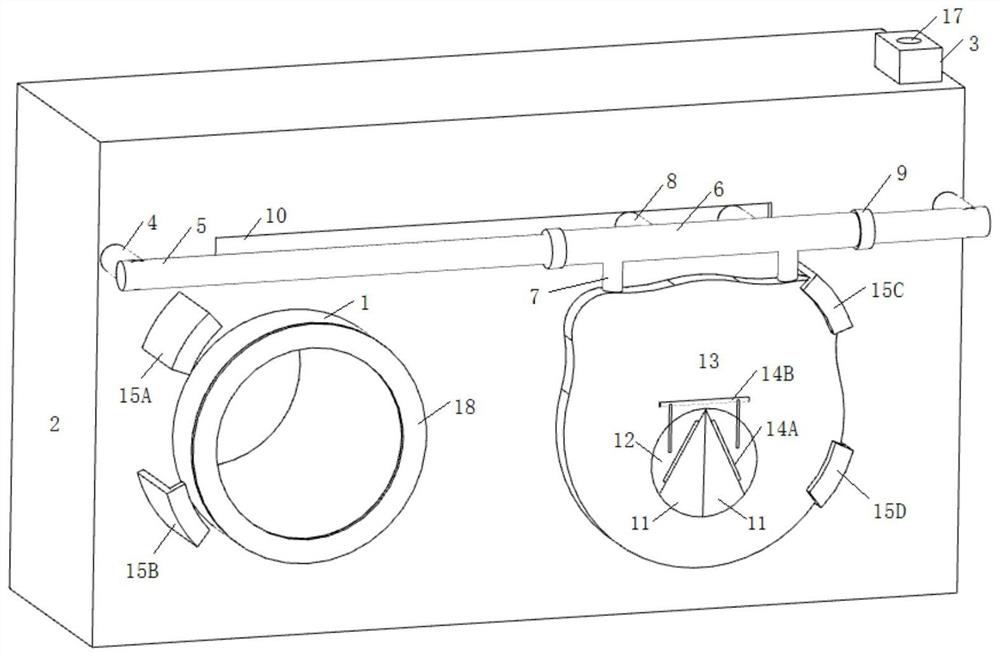

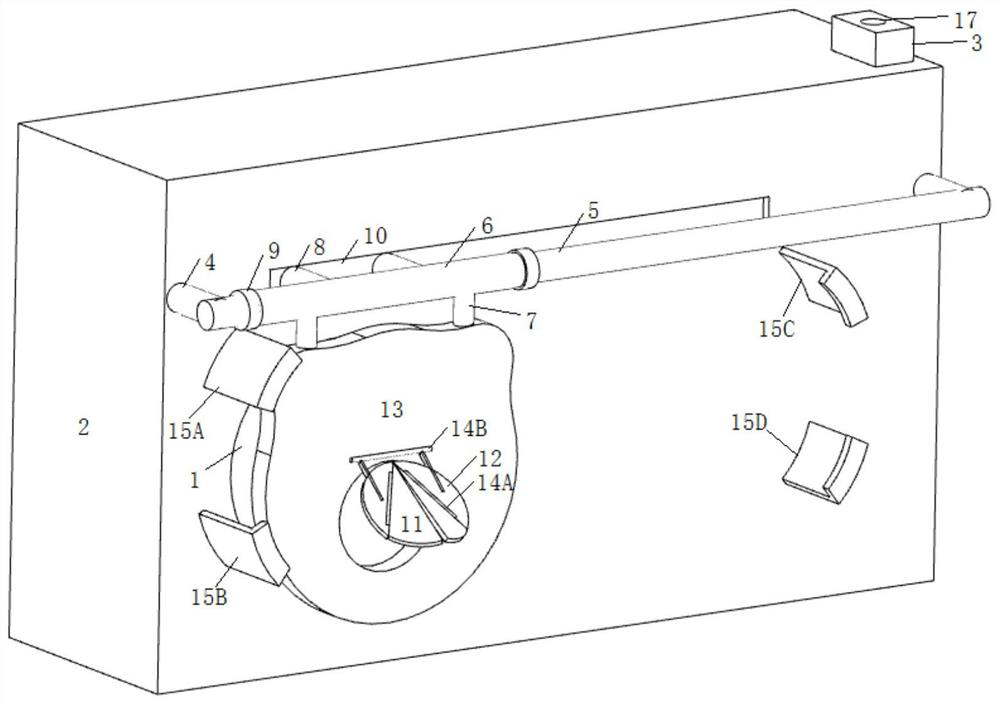

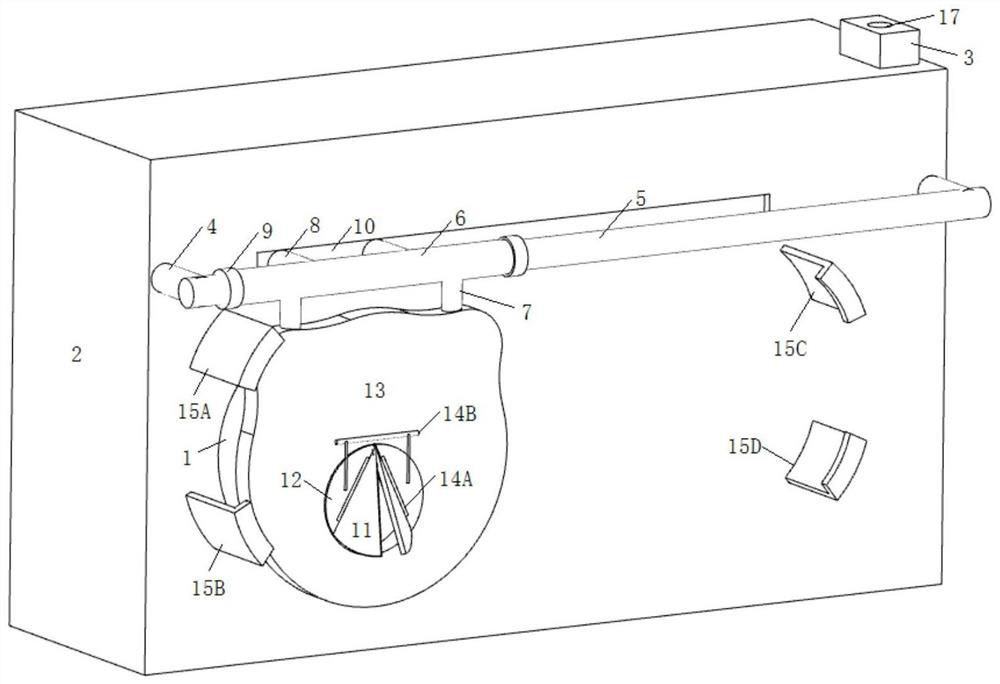

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0049] Such as Figure 1-Figure 11 As shown, a horizontal pull type three-stage flap door of the present invention comprises:

[0050] Outlet pipe 1, back wall of outlet pool 2, motor 3, first-level fixed rod 4, second-level fixed rod 5, transmission sleeve rod 6, transmission connecting rod 7, sliding rod 8, bushing 9, sliding track 10, first-level clapper Door 11, second-stage flap door 12, third-stage flap door 13, flap door shaft 14 (first-stage flap door shaft 14A, second-stage flap door shaft 14B), fixed groove 15 (fixed groove I 15A, fixed groove II 15B, fixed groove III 15C , fixing slot IV 15D), piezoelectric sensor 16 (piezoelectric sensor I 16A, piezoelectric sensor II 16B, piezoelectric sensor III 16C, piezoelectric sensor IV 16D), motor shaft 17, pipeline cushion 18, flexible material layer 19, sealing layer 20, Sliding layer 21, gear box 22, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com