Hydraulic lifting method for steel structure building

A technology of hydraulic lifting and steel structure, which is applied in the processing of building materials, construction, building construction, etc., and can solve problems such as low efficiency, long time consumption, and delay in construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention are described in detail below, and the embodiments described with reference to the drawings are exemplary, and embodiments of the present invention are described in detail below.

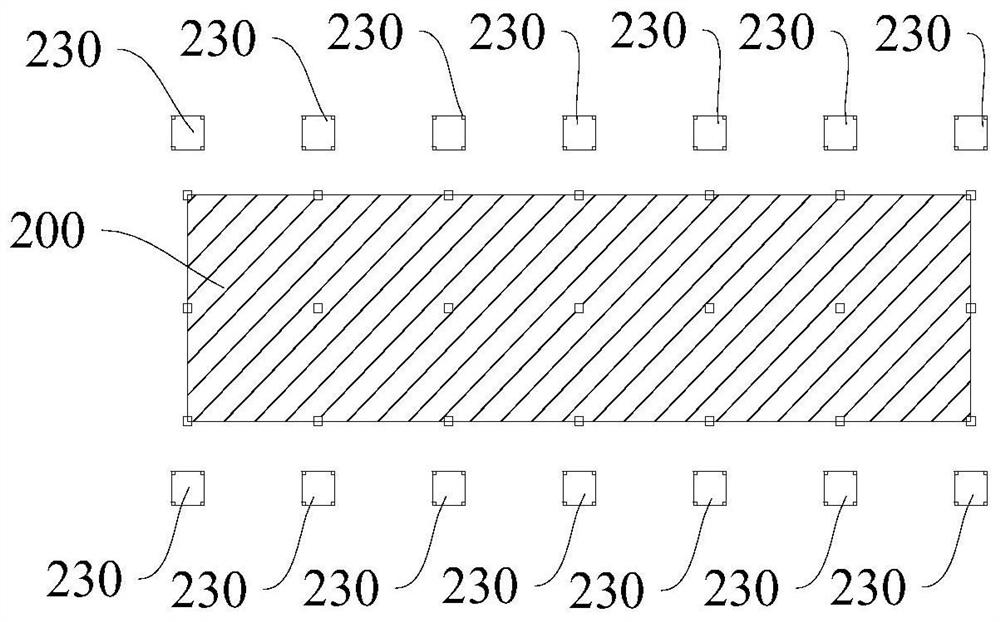

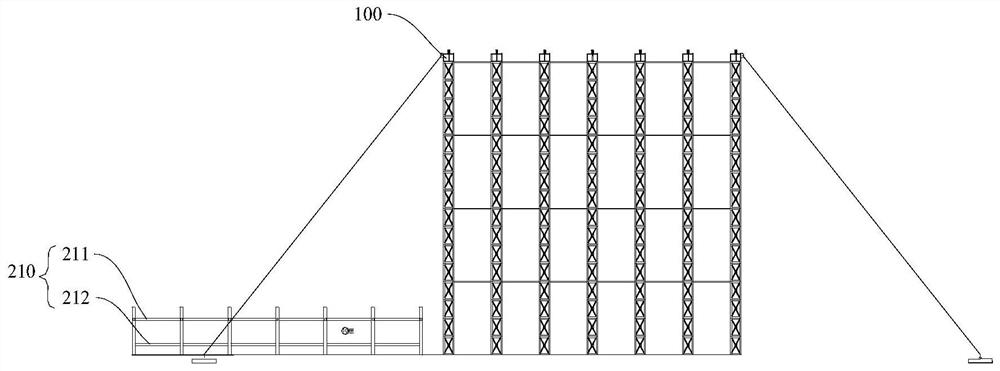

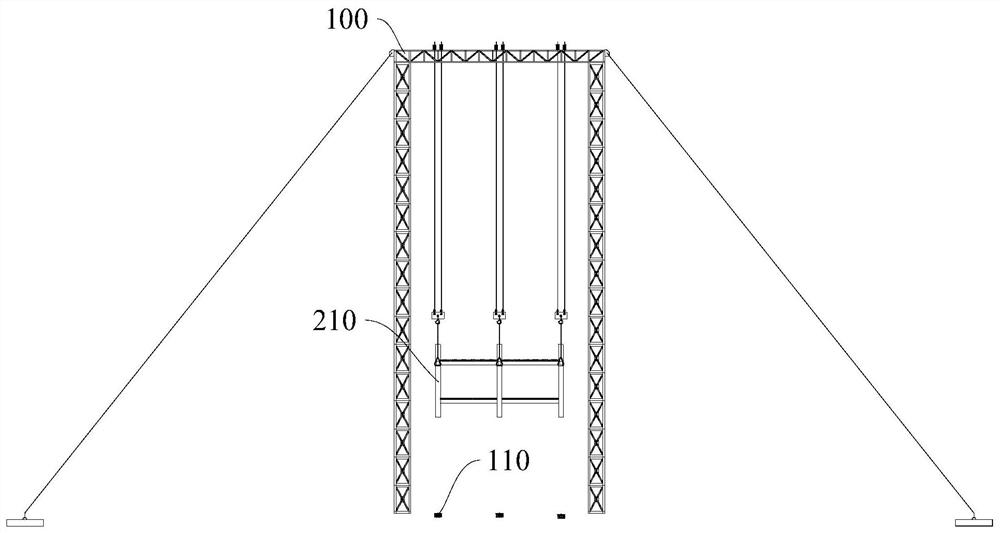

[0032] Refer below Figure 1-Figure 9 Describe the hoisting and lifting method of the steel structure building 200 according to the embodiment of the present invention, including the following steps: assembling the hydraulic hoisting equipment 100; the hydraulic hoisting equipment 100 is used to assemble the steel structure building 200 to improve work efficiency; A second building module 220, the first building module 210 at least includes two planes of the roof 211 and the top floor 212, and the second building module 220 at least includes two floors below the top floor 212; When constructing the building 200, the steel structure building 200 can be divided into a first building module 210 with a roof 211 and a top floor 212, and a second building with m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com