Non-contact bearing dynamic pressure supporting device and manufacturing method thereof

A technology of supporting device and manufacturing method, which is applied to pump devices, electromechanical devices, components of pumping devices for elastic fluids, etc., to achieve the effect of long-term operation of product equipment and excellent product equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0025] It should be noted that the orientation terms such as left, right, up, down, top, and bottom in this embodiment are only relative concepts, or refer to the normal use status of the product, and should not be regarded as having restrictive.

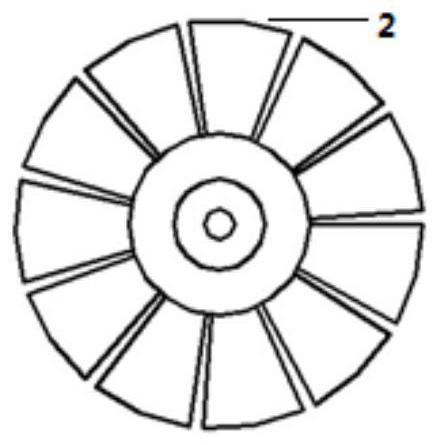

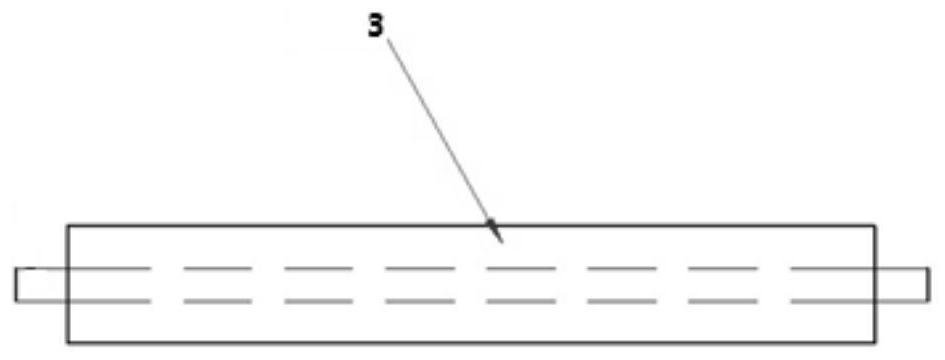

[0026] The invention proposes a non-contact bearing dynamic pressure support device and a manufacturing method thereof, which relate to the application of ultra-high-speed non-contact bearing wind output, high-speed blowing and rotating devices, and ultra-high-speed turbocharged dynamic pressure support devices; solve the problem of the service life of ordinary contact bearings Difficulties, using non-contact bearings,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com