Scheduling optimization method and system based on resource-constrained project scheduling problem model

A technology with limited resources and scheduling problems, applied in genetic models, resources, manufacturing computing systems, etc., can solve problems such as no resources available, difficult scheduling of delivery processes, and impact on delivery progress, so as to reduce delay risks and improve The effect of delivery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

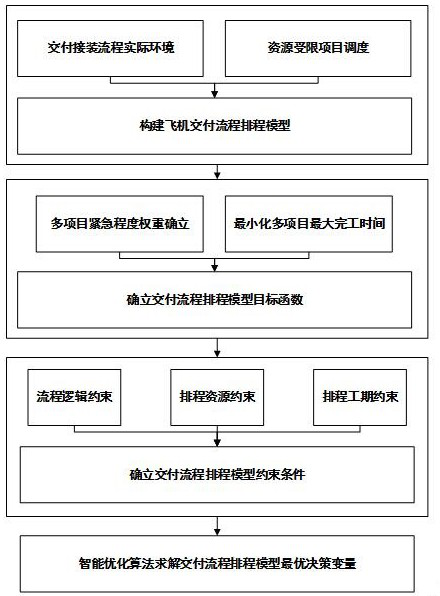

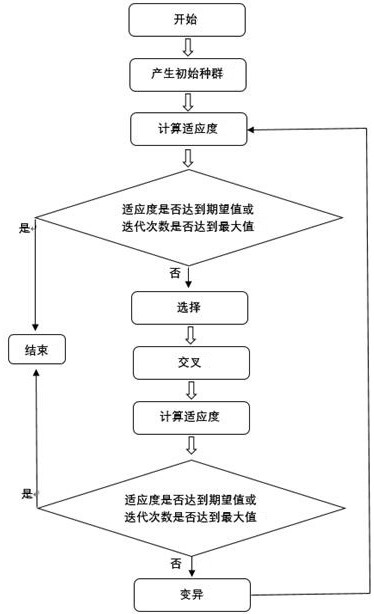

Method used

Image

Examples

Embodiment 2

[0128] On the basis of Embodiment 1, this embodiment provides a scheduling optimization method based on a resource-constrained project scheduling problem model. Further, when resources and space are satisfied, when the execution time of the existing delivery process is inconsistent with the planned time When , the current tipping project plan cannot guide project execution, so the rescheduling model needs to be triggered.

[0129] (1) The rescheduling model triggered by inspection time delay and problem disposal delay is as follows:

[0130]

[0131]

[0132]

[0133]

[0134]

[0135]

[0136]

[0137]

[0138]

[0139] The fundamental difference between this rescheduling model and the complete pick-up project scheduling model in Example 1 is that the pick-up project process in the re-scheduling model is limited to the pick-up process affected by the inspection time delay and problem handling delay, not all Pickup process.

[0140] Among them, set ...

Embodiment 3

[0167] For the scheduling problem of part of the process of delivery acceptance, this embodiment provides a scheduling optimization system based on a resource-constrained project scheduling problem model. The system is divided into three modules, including model input module, model main module and model output module.

[0168] 1) Model input module:

[0169] The input form is EXCEL form data, which mainly inputs the main relevant parameters of the pick-up process. It mainly includes the following data:

[0170] Table 1 Information on the input fields of the scheduling model of the pick-up process

[0171] field name Field Type illustrate Activity process int Numbering the pick-up process Prior process int or str The set of preceding processes corresponding to this process Process time int The execution period of the pick-up process Resource Requirements 1 float The demand for resource 1 in this process Resource Requireme...

example

[0174] Step 1. First, the user enters relevant information into the form according to the actual situation of the delivery and assembly process, resource reserves, and customer needs;

[0175] Step 2. Input the table file path in step 1 into the GUI interface (the system has defaulted); and improve other relevant calculation information, and finally select the relevant output information, such as Figure 4 shown.

[0176] 2) Model main module:

[0177] Such as Figure 5 As shown, the main body of the model mainly uses the GUI visualization window to interact with the user. After the user confirms the relevant information of the input module, select the input file path and file name in the GUI window, and select the relevant demand parameter constraints, and click Calculate to realize the model main module .

[0178] Module instance:

[0179] Step 1. After setting the input information, click the Calculate button, and the main body of the process scheduling model will start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com