GaN compatible driving circuit

A technology of compatible drive and circuit, which is applied in the field of GaN compatible drive circuit, can solve the problems of not being able to drive GaN devices without integrated drive, low on-resistance and gate charge, and demanding drive performance, achieving convenient iteration, high reliability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

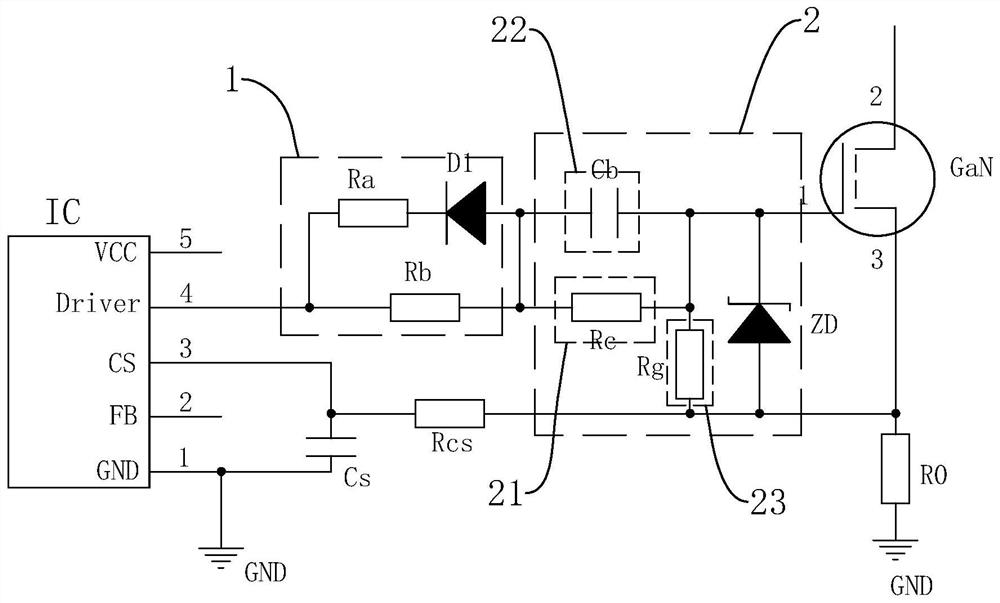

[0038] refer to figure 1 , the GaN compatible drive circuit includes a drive chip IC, a MOS drive module 1 and a GaN drive compatible module 2, the drive terminal of the drive chip IC is connected to the input terminal of the MOS drive module 1, the GaN drive compatible module 2 includes a voltage limiting unit 21, an acceleration unit 22 and a voltage dividing unit 23, the input end of the voltage limiting unit 21 is connected to the output end of the MOS drive module 1, the output end of the voltage limiting unit 21 is connected to the input end of the voltage dividing unit 23, and the gate of the N-type field effect transistor, The output end of the voltage dividing unit 23 is connected to the source of the N-type field effect transistor and the driving chip IC, and the accelerating unit 22 and the voltage limiting unit 21 are connected in parallel.

[0039] In this embodiment, the MOS drive module 1 includes a first resistor Ra, a diode D1 and a second resistor Rb, one end...

Embodiment 2

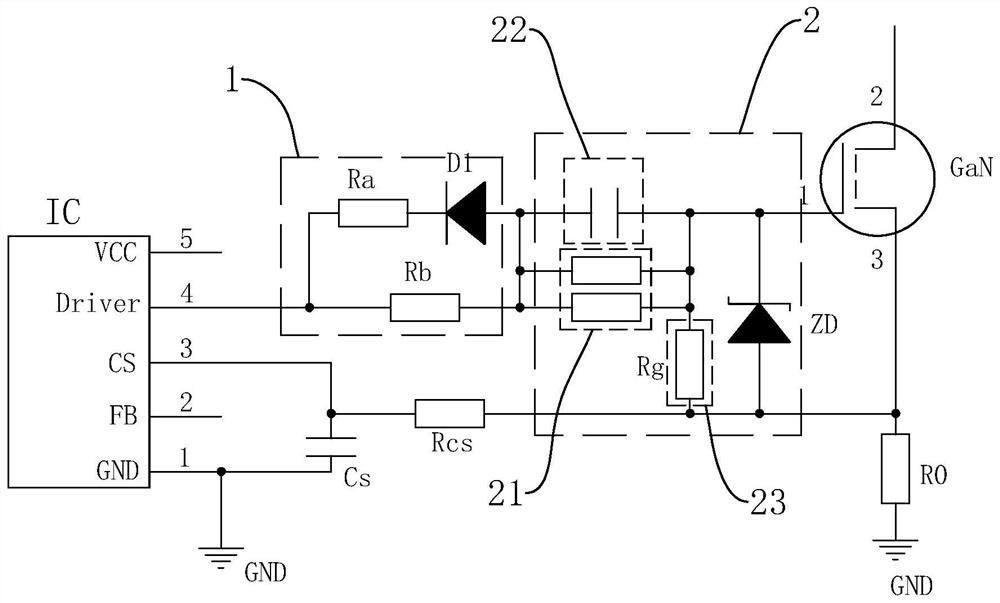

[0053] refer to figure 2 , The difference between this embodiment and Embodiment 1 is that there are multiple voltage limiting resistors, and multiple voltage limiting resistors are connected in series or in parallel.

Embodiment 3

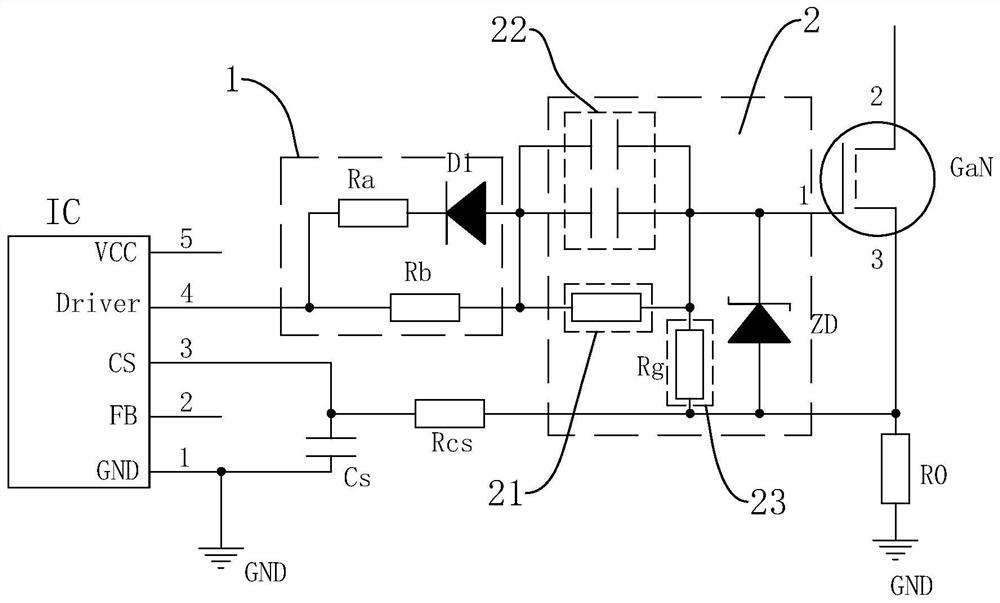

[0055] refer to image 3 , The difference between this embodiment and Embodiment 1 is that there are multiple speed-up capacitors Cb, and multiple speed-up capacitors Cb are connected in parallel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Regulator value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com