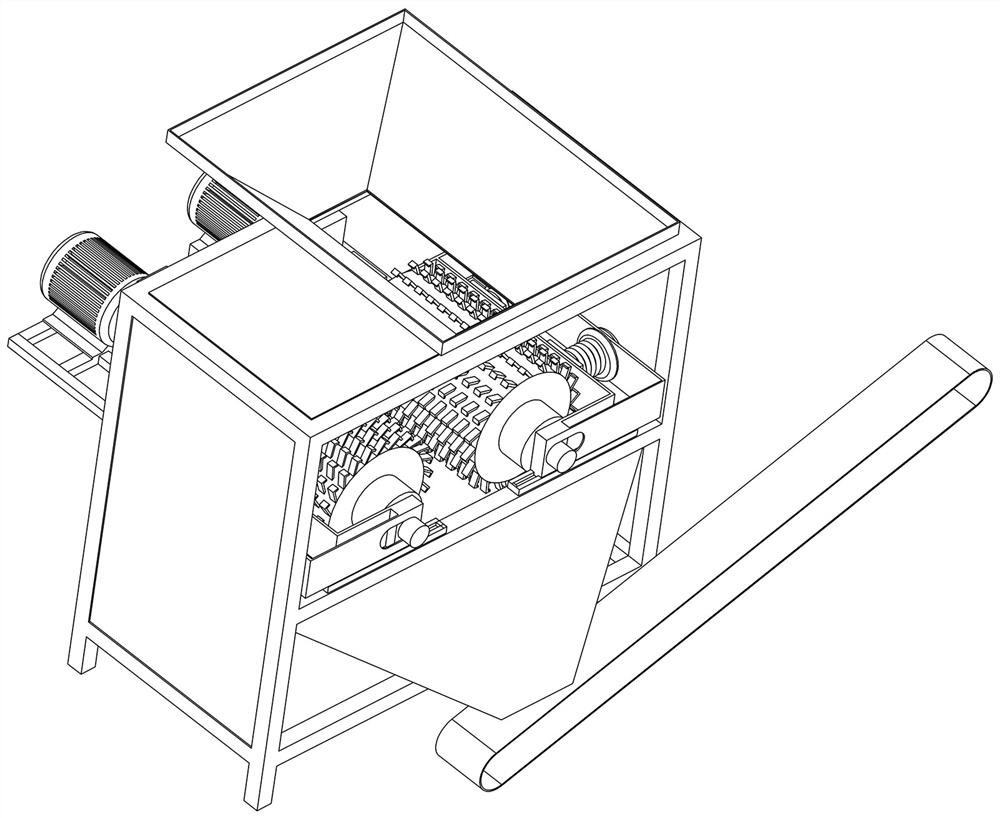

Ultra-large decoration garbage reducing, bag breaking and feeding all-in-one machine and manufacturing method thereof

A technology for decoration waste and manufacturing methods, applied in packaging, conveyors, transportation and packaging, etc., can solve problems such as lack of recycling technology and equipment, difficulties in transportation and crushing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

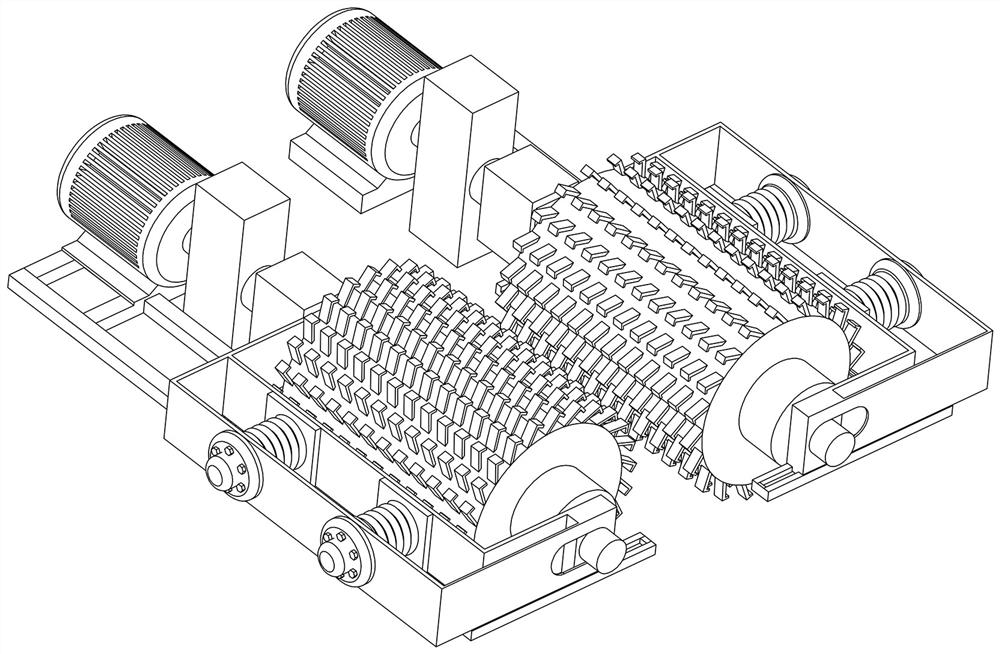

[0020] 1. The feeding device sends the garbage generated from home decoration and public facilities decoration to the "ultra-large block variable diameter bag breaking system". , aluminum packaging, various decoration materials and other materials, the diameter of the material is changed through the "adjustable extrusion method", which is called "variable diameter"; Meet the mechanical performance requirements of the lower equipment.

[0021] 2. The feeding device sends the garbage generated from home decoration and public facilities decoration to the "ultra-large variable diameter bag breaking system". "Adjustable extrusion method" is used to "break the bag". The purpose of breaking the bag is to ensure the smooth transportation of garbage to the lower level and meet the mechanical performance requirements of the lower level equipment.

[0022] 3. The feeding conveyor sends the ultra-large pieces of decoration garbage to the lower "primary separator of light and heavy materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com