Tunnel dust removal system and method

A dust removal system and tunnel technology, which is applied in mine/tunnel ventilation, dust prevention, earthwork drilling and mining, etc. It can solve the problems of difficult tunnel ventilation and excessive dust in the air, so as to improve the working environment in the tunnel, improve the processing efficiency, The effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

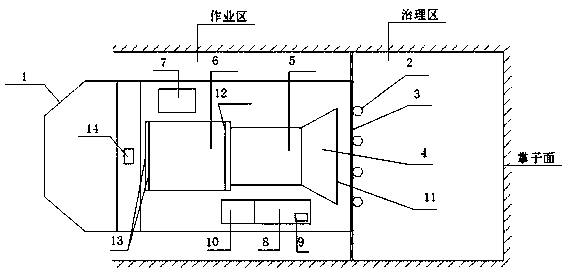

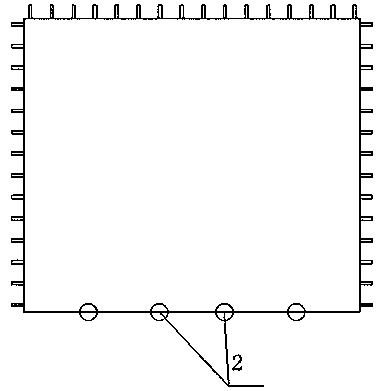

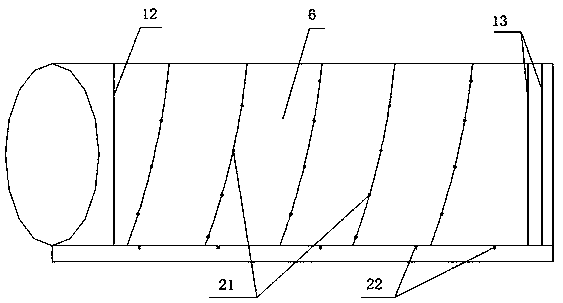

[0027] Embodiment: An autonomous air purification system for a tunnel consists of a carrier vehicle 1, an on-board engine 7 (environmentally friendly), a booster pump 9, a front dust-repelling fog cannon 2, a dust-proof fog curtain 3, a dust-absorbing cover 4, a screen 11, a wind Chassis 5, filter box 6, decompression device 12, filter screen 13, dedusting agent silo 10, detector 14, etc., using dust isolation mist curtain 3 to isolate the treatment area and operation area, before starting the dust isolation mist curtain 3 at the same time Equipped with the dust blowing fog cannon 2, the dust can be reduced outside the machine. The waste gas is sucked into the filter box 6 by a fan for deep purification, and enters the filter cartridge through the filter screen 13 for dust removal and purification again, and is discharged after being tested. The invention adopts a combination of physical and chemical methods, sprays dust on the periphery, and uses dust suppressant and water mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com