Preparation method of natural composite fruit powder

A kind of fruit powder, natural technology, applied in the field of preparation of compound pomace powder, can solve the problems of difficult drying, slow drying speed, poor rehydration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

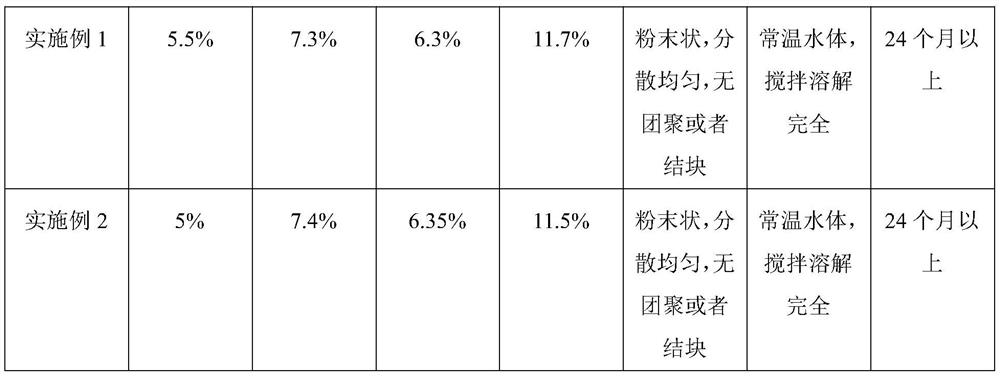

Embodiment 1

[0031] (1) Acceptance of raw materials: The mulberry variety is the "Big Ten" variety (the industry's conventional mulberry variety model) with strong fruit aroma, bright color and high utilization rate. (refuse to purchase pesticide residues, heavy metals exceeding the standard, diseased and insect fruit, moldy fruit, rotten fruit, immature fruit) can be processed; blueberries and red bayberry are also picked and fully mature quality, qualified for acceptance (refuse to purchase pesticide residues, heavy metals exceeding the standard, Diseased fruit, moldy fruit, rotten fruit, immature fruit) can be processed;

[0032] (2) Pedicel removal: remove the fruit pedicles at the bottom of mulberry, blueberry and red bayberry to reduce the bitterness of fruit powder;

[0033] (3) Cleaning and selection: wash away the silt and sundries with running water; manually remove impurities such as mildew, unripe fruits, branches and leaves on the conveyor belt;

[0034] (4) Crushing: The sel...

Embodiment 2

[0043] (1) Acceptance of raw materials: The mulberry variety is the "Big Ten" variety (the industry's conventional mulberry variety model) with strong fruit aroma, bright color and high utilization rate. (refuse to purchase pesticide residues, heavy metals exceeding the standard, diseased and insect fruit, moldy fruit, rotten fruit, immature fruit) can be processed; blueberries and red bayberry are also picked and fully mature quality, qualified for acceptance (refuse to purchase pesticide residues, heavy metals exceeding the standard, Diseased fruit, moldy fruit, rotten fruit, immature fruit) can be processed;

[0044](2) Pedicel removal: remove the fruit pedicles at the bottom of mulberry, blueberry and red bayberry to reduce the bitterness of fruit powder;

[0045] (3) Cleaning and selection: wash away the silt and sundries with running water; manually remove impurities such as mildew, unripe fruits, branches and leaves on the conveyor belt;

[0046] (4) Crushing: The sele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com