A device and method for in-situ lateral movement of a ship's caudal fin structure

A technology of ships and stern fins, which is applied in the field of ship stern fin structure in situ traversing and floating devices, which can solve the problems that the dock space cannot be fully utilized, and achieves the advantages of easy disassembly and maintenance, small storage area, and improved use efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

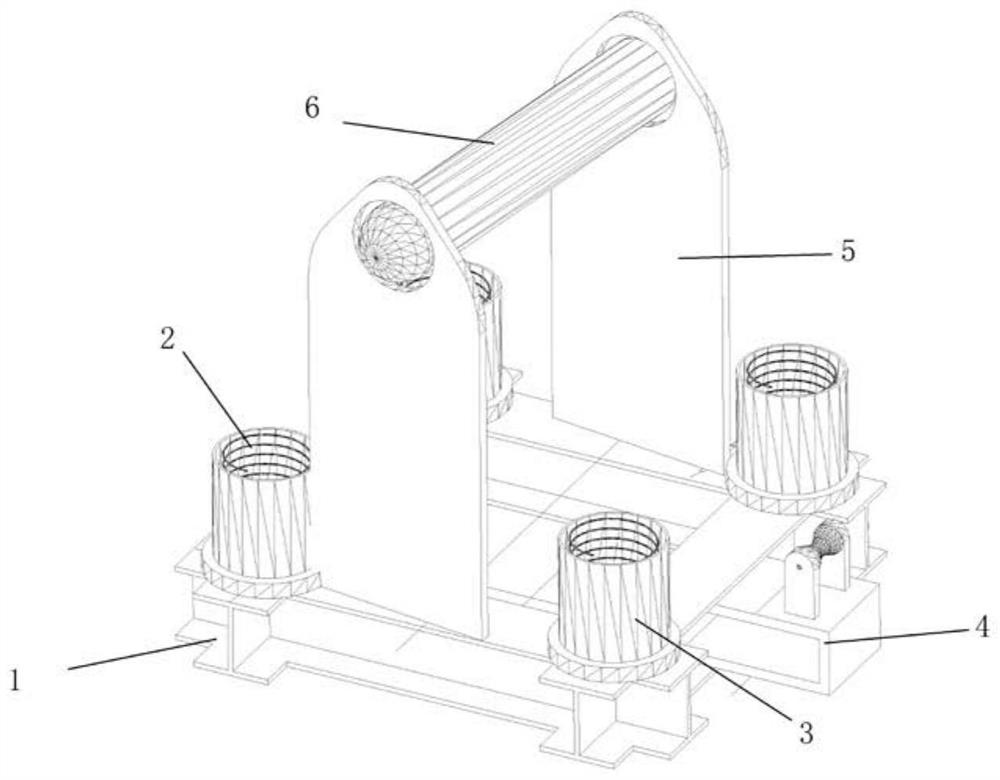

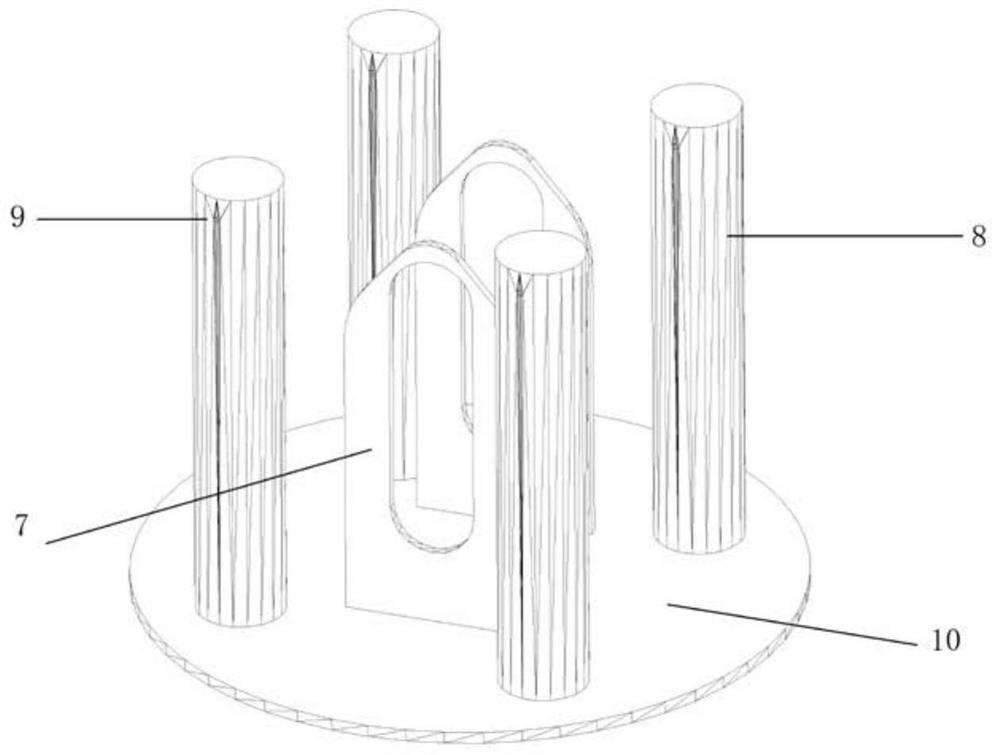

[0034] This embodiment provides an in-situ lateral movement and floating device for a ship's tail fin structure, which includes a lower support structure, an upper support structure and a high support pipe 14, and the lower support structure includes a support base 1, a fixed sleeve 3, a fixed eye plate 5 and a base The fixed pulley 4, the support base 1 is rectangular, the fixed sleeve 3 is installed on the four corners of the support base 1, the top support spring 2 is arranged inside the fixed sleeve 3, and the fixed eye plate 5 is installed on the opposite side of the support base 1. On both sides, the fixing eye plate 5 is provided with positioning holes, and the positioning holes are provided with connecting pins. The upper support structure includes a support pipe base 10, a fixed pipe column, and a guide eye plate 7. The fixed pipe column and the guide eye plate 7 are welded to the bottom of the support pipe base 10. The fixed pipe column matches the fixed sleeve 3, and...

Embodiment 2

[0036] The present embodiment provides a method for in-situ lateral movement and buoyancy of a ship caudal fin structure, including the following steps:

[0037] Step 1. Before the ship's tail fin structure is mounted, set the in-situ traverse floating device on the support position of the stern, weld the support base 1 on the embedded part of the dock ground, and embed the fixed pipe string 8 on the support pipe base 10. into the fixed sleeve 3, through the fixed eye plate 5 and the guide eye plate 7 through the connecting shaft pin 6. At this time, due to the force of the top support spring, the support pipe base 10 and the fixed pipe column 8 are in a suspended state.

[0038] Step 2: Ballast the 5-ton ballast iron on the base of the support pipe to make the entire traverse floating device in a compressed state, and use a pin to pass through the locking pin hole 9 on the side of the fixed pipe string 8 and the fixed sleeve 3, so that the whole The jacking spring is kept in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com