Metal plating fixing device convenient to control

A fixing device and metal plating technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problem of easy falling off of plated parts, achieve the effect of improving plating efficiency, good stability, and preventing detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

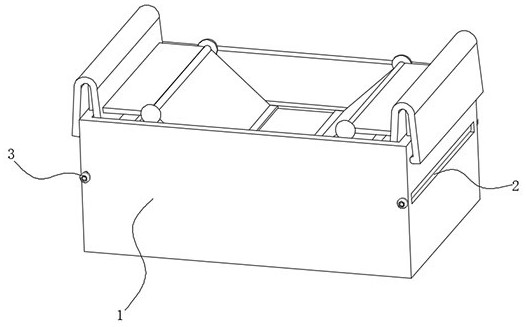

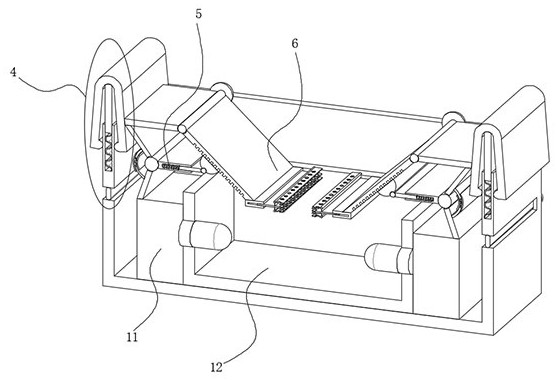

[0032] use Figure 1-Figure 7 A controllable metal plating fixing device according to an embodiment of the present invention will be described as follows.

[0033] Such as Figure 1-Figure 7 As shown, a metal plating and fixing device that is easy to control according to the present invention includes a coating box 1, and the two sides of the inner cavity of the coating box 1 are symmetrically opened with a through opening, and the two sides of the outer surface of the coating box 1 A release handle 3 is rotatably connected through the turning port, and the two sides of the outer surface of the coating box 1 are symmetrically provided with locking slots 2 .

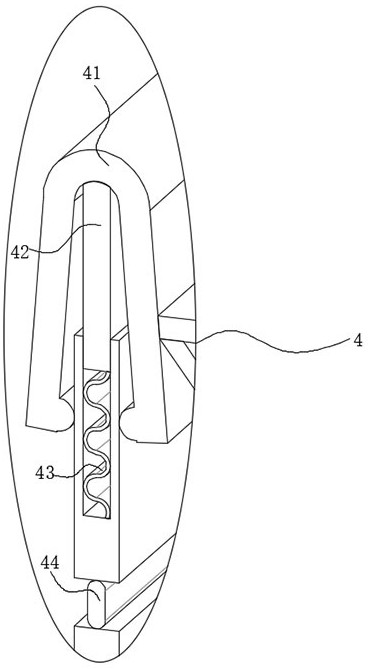

[0034] The coating box 1 includes a clamping device 4, one side of the outer surface of the clamping device 4 is fixedly connected with a splint 6 for plating, and one side of the lower surface of the splint 6 for plating is fixedly connected with a three-way transfer device 5, The bottom end of the three-way switching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com