Oil and gas well casing discarding operation device and method

A technology for operating devices and oil and gas wells, which is applied to casings, drill pipes, drilling equipment, etc., can solve the problems of heavy sliding base, unstable operation methods, and high operating costs, so as to improve cutting operation efficiency and improve clamping The effect of stability and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

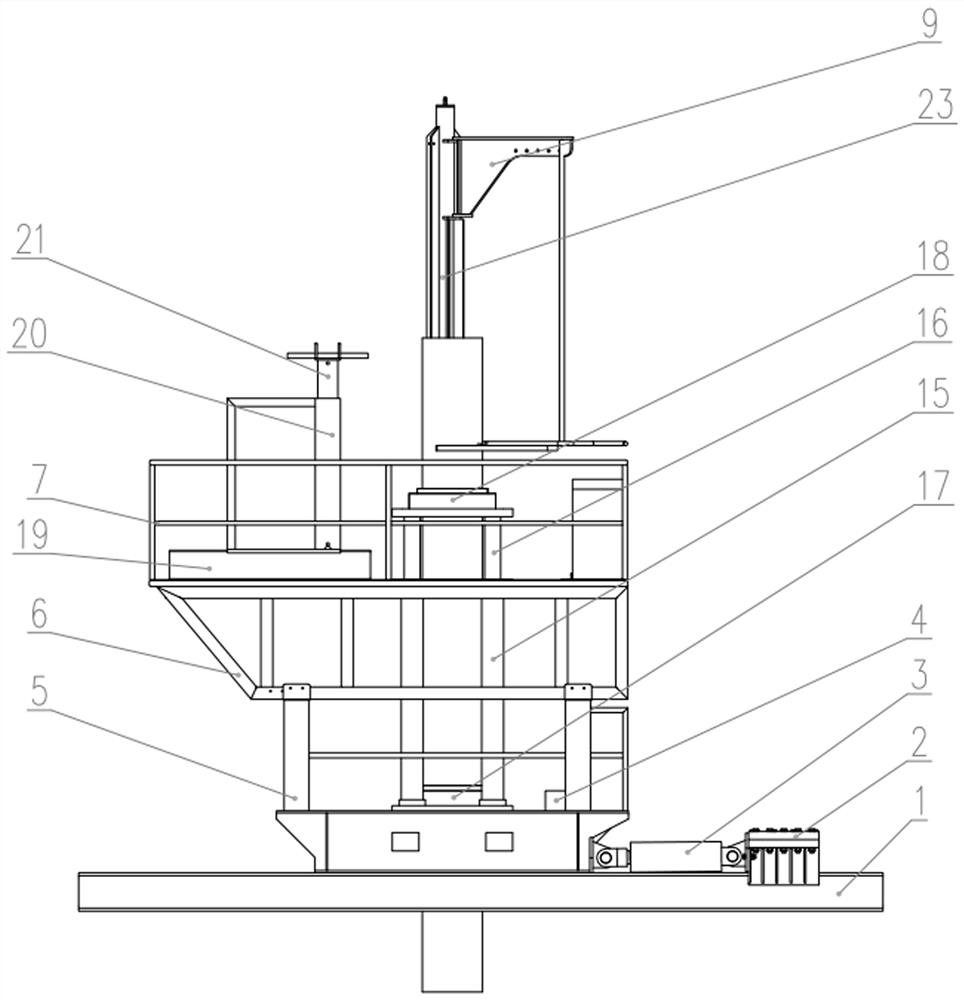

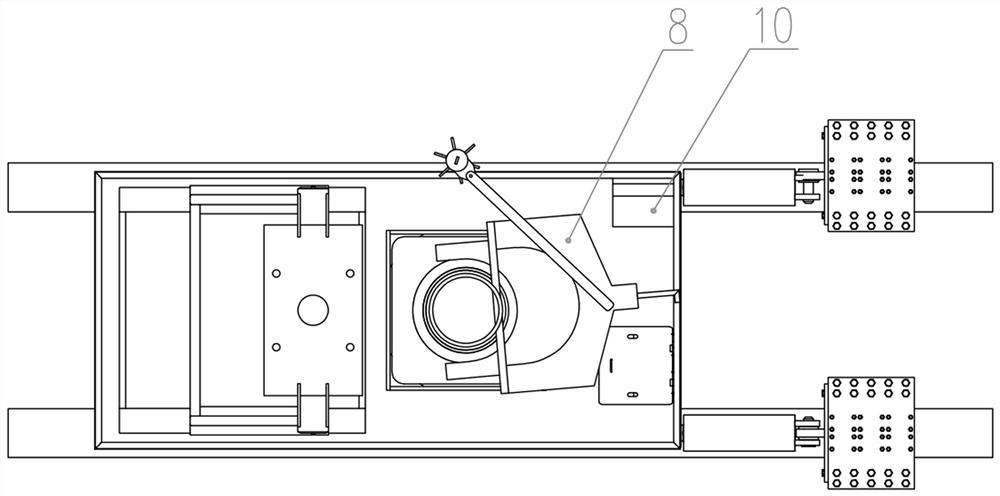

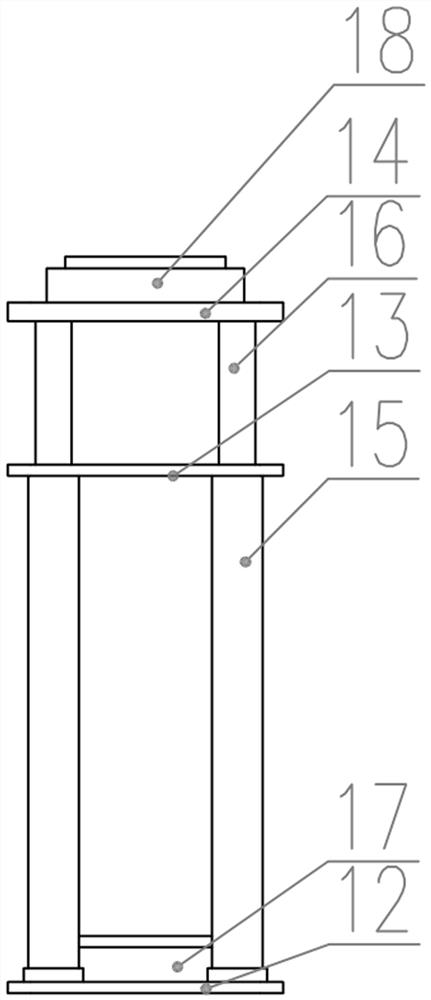

[0046] The preferred solution is as Figure 1 to Figure 5 As shown, a casing disposal operation device for oil and gas wells is provided. A lower operating platform 5 is provided at the bottom of the operating frame, and a lifting device is provided on the lower operating platform 5. The movable end of the lifting device is engaged with the floating hydraulic casing clamp The tile 18 is connected, and the bottom of the lifting device is provided with a fixed hydraulic casing slip 17; the work frame is provided with a boom 23, and the boom 23 is provided with a rotating boom 9, which is used to hang the casing cutting device 8 and / or punching device.

[0047] The lifting device is used to drive the floating hydraulic casing slips 18 to move up and down, and the floating hydraulic casing slips 18 cooperate with the fixed hydraulic casing slips 17 for reciprocating lifting of the casing. The casing cutting device 8 is used to cut the pulled casing. The rotating boom 9 on the boo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com